I.Technical Data for KJZ series

|

Material cutting |

Cold roll steel, hot roll, galvaniz roll, stainless steel , aluminum |

|

Item |

Unit |

Range |

|

Thickness |

MM |

0.3-2, 0.5-3, 1-6, 3-8. |

|

Width |

MM |

800, 1250,1500,2000 |

|

Load weight |

T |

15-20 |

|

Leveling precision |

MM/M2 |

1 |

|

Feed precision |

MM/M |

0.5 |

|

Line speed |

M/MIN |

40. |

|

Power |

KW |

95 |

A unique concept in high speed, zigzag roll feeding, the DXY/EV allows parts to be fed in a staggered pattern for optimum material yield material is fed in a simultaneous X-Y movement allowing incoming material to travel at high speeds through the rolls on the X-Axis. At the same time, the Y-axis movement is controlled by a rotating linear ball screw which maximizes speed and provides high torque and low inertia.

The zigzag feed is compact and can be easily mounted to any side of press, the roll feed is driven by an AC servo motor while the Y axis movement of the feed is powered by an servo motor and linear ball screw. The working zigzag as following drawing

Servo driven feeds share many of the advantages with the press driven variety, such as minimal space requirement, low maintenance, and high speeds. However, servo feeds also provide benefits that press driven units cannot. The fact that they utilize a microprocessor based control gives them an added dimension. Features such as programmable move patterns, self diagnostics, auto correction, and the ability to communicate with automation - just to name a few - set them apart from other types of feeds.

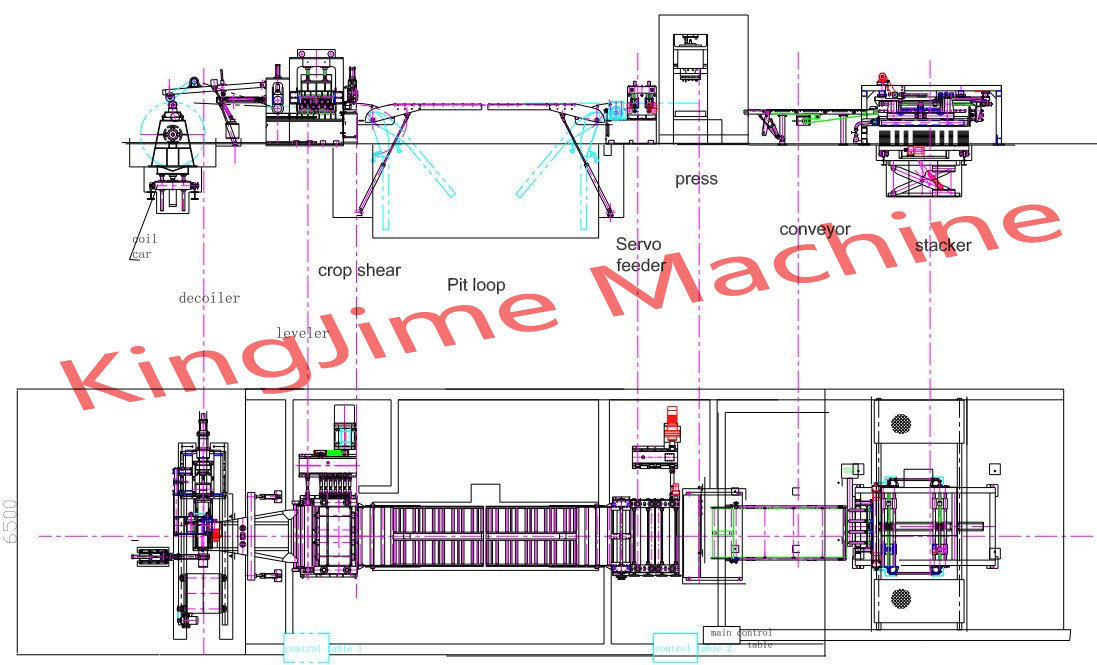

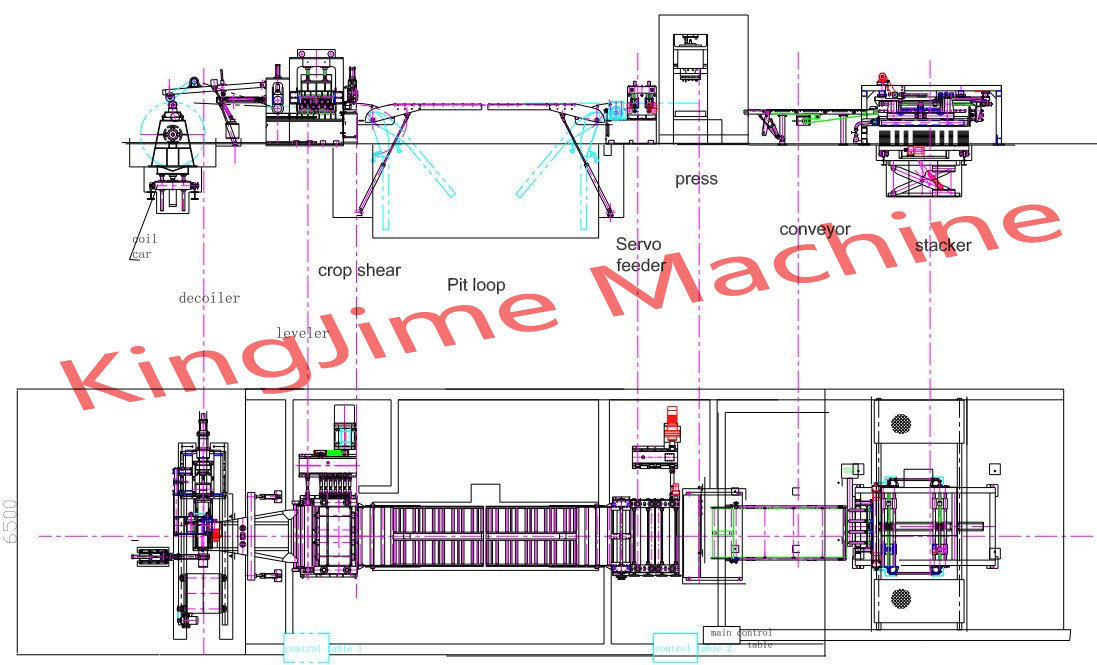

III. LIST OF EQUIPMENTS UNDER SCOPE OF SUPPLY:

1. Coil car

2. Decoiler

3. peeler table

4. precision leveler

5. Loop Bridge

6. Side Guide Roller

7. ZIG ZAG Servo feeder

8. Press machine

9. Conveyor table

10. stacking table

11. lifting table

12. Hydraulic Systems

13. Pneumatic Systems Electrical System PLC Control