drilling desander for soild control system

group nameSolids Control System

-

Min Order1 piece

modelQJ

-

update timeMon, 08 Apr 2013 00:35:44 GMT

Paramtents

Condition New

size 8"&10"

Packging & Delivery

Min Order1 piece

Briefing

2.rapid treatment speed

3.less energy consumption

4.occupying small

Detailed

1.desander has large disposal capacity

2.rapid treatment speed

3.less energy consumption

4.occupying small

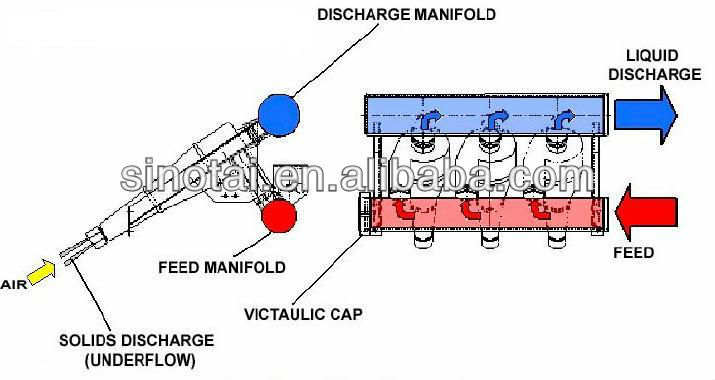

Desander

Main feature:

1.Desander is the second class and the third class solid control equipment to treat the drilling fluid.

2.According to the size of the cone diameter, it is divided into desander and desilter.

3.Usually the cone diameter is more than 6″is called desander and used as the second-control equipment in drilling operation.

4.We commonly used 8 "and 10" cones desander to separate solid-phase particle size 47-76μm in the drilling fluids

5. It apply for directional drilling.

The main technical performance and specification for the desander:

Model | QJ200S | QJ250S | QJ300S | QJ200 | QJ250 | QJ300 |

Capacity | ≤120m3/h ≤528GPM | ≤180m3/h ≤792GPM | ≤240m3/h ≤1056GPM | ≤120m3/h ≤528GPM | ≤180m3/h ≤792GPM | ≤240m3/h ≤1056GPM |

Cone size | 8" | 10" | 12" | 8" | 10" | 12" |

Pressure | 0.15~0.35Mpa | |||||

Inlet Size | 75-100mm | 100-150mm | 150-200mm | 75-100mm | 100-150mm | 150-200mm |

Outlet Size | 125-150mm | 150-200mm | 200-250mm | 125-150mm | 150-200mm | 200-250mm |

Separation size | 47-76μm | 47-76μm | 47-76μm | |||

Screen area | 1.0m2(600×1600mm) | No Under fluids Shaker | ||||