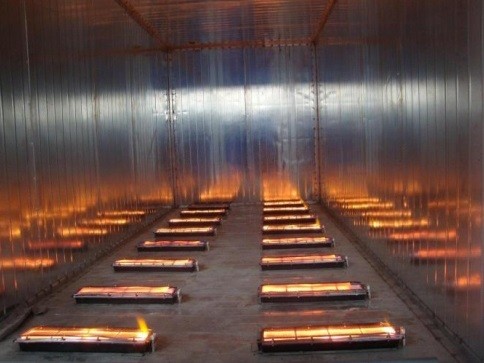

Infrared Gas Heating Powder Coat Oven

group nameInfrared Powder Coating Oven

-

Min Order1 piece

brand nameCOLO powder coating machine

modelCOLO- Infrared Oven

payment methodT/T, L/C, MoneyGram

-

update timeWed, 18 Feb 2026 22:12:03 GMT

Paramtents

Delivery Time 7-15 Working Days

Shipping By Sea

Application Metal Finishing Industry

Packging & Delivery

Min Order1 piece

Briefing

Detailed

|

Model

|

COLO- Infrared Oven

|

|

Working Dimension (mm)

|

2.4width x 2.2height x 3.2 depth(mm)

|

Overall Dimension (mm) | 2.6 width x 2.4 height x 3.4depth(mm) |

|

Power supply

|

Gas/Diesel/LPG

|

Voltage | 220V/380V(50-60Hz) |

Motor power | 4kw |

Warm-up Time | 15-30min (180°C) |

Temperature stability | < ± 3-5°C |

Temperature max. | 250°C |

Circulation/ Air flow | Vertical ,Variable through holes on the walls |

Ventilation performance | 1000-1677m3/h |

Transportation | Trolley |

You need a product

You May Like

- Nearest port for product export

- NINGBO, SHANGHAI

- Delivery clauses under the trade mode

- FOB, CFR

- Acceptable payment methods

- T/T, L/C, MoneyGram