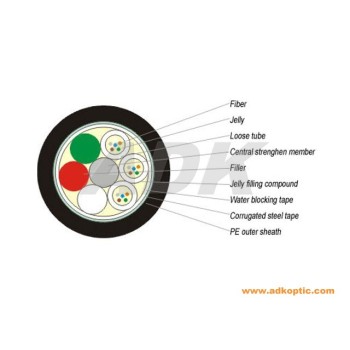

GYTS Optical Fiber Cable

group nameOutdoor Optical Fiber Cable

-

Min Order5 kilometer

brand nameADK

modelGYTS

payment method

-

update timeTue, 22 Jan 2013 20:03:55 GMT

Packging & Delivery

Min Order5 kilometer

Briefing

GYTS optical fiber cable, 8/16/24/48/96/144 fibers, G652D, steel strength member, 1km, wooden drum package.

Detailed

Features

◇ Low dispersion and attenuation

◇ Proper design, precise control for fiber excess length and distinct stranding processrender the cable excellent mechanical and environmental properties

◇ The armoring of corrugate steel tape make cable have nice properties of moisture resistanceand crush resistance

◇ With small cable diameter, light cable weight, easily to lay

◇ Operating Temperature : -40~+60 ℃

Description

Loose tube style, optical fiber cable with metallic central strength member of steel wire/strand and moisture barrier inner sheathed. Cable protected by a black PE oversheath, suitable for duct or aerial application. Tubes contain optical single-mode or multimode fibers colour coded as per color coding scheme.

Parameter

Fiber count | Cable dia.(mm) | Cable net weight(Kg/km) | Min. bending radius(mm) | Min. tensile strength(N) | Min. crush pressure(N/100mm) | |||

Static state | Dynamic state | Short term | Long term | Short term | Long | |||

term | ||||||||

-30 | 11 | 123 | 110 | 220 | 1500 | 600 | 1000 | 300 |

32-36 | 11.6 | 144 | 120 | 240 | 1500 | 600 | 1000 | 300 |

38-60 | 12.3 | 155 | 130 | 260 | 1500 | 600 | 1000 | 300 |

62-72 | 13.1 | 190 | 140 | 280 | 1500 | 600 | 1000 | 300 |

74-84 | 13.9 | 208 | 140 | 280 | 1700 | 600 | 1000 | 300 |

86-96 | 14.7 | 228 | 150 | 300 | 1800 | 600 | 1000 | 300 |

98-108 | 15.5 | 247 | 160 | 320 | 2000 | 600 | 1000 | 300 |

110-120 | 16.3 | 268 | 170 | 340 | 2200 | 600 | 1000 | 300 |

122-132 | 17.1 | 290 | 180 | 360 | 2300 | 600 | 1000 | 300 |

134-144 | 17.9 | 313 | 180 | 360 | 2500 | 600 | 1000 | 300 |

Item | Specification |

Central strength member | All dielectic FRP |

Tube material | Polybutylene terephtalate |

Color of loose tubes | Blue, orange, green, bidder can offer coloers and should be stated |

Color of fibers in per tube | Blue, orange, green, bidder can offer coloers and should be stated |

Tube filling compound | Thixotropic jelly |

Core filling compound | Pelrolcum jelly |

Ripcord | Aramid or polyester cord |

Tape wrap | Polyester tape |

Identification tape marking | AFPC syria |

Inner jacket | 1.0±0.1mm thickness |

Armor | Corrugated steel tape |

Outer jacket | 1.5±0.1mm thickness |

Surface marking | AFPC syria |

Optical characteristics | |

Attenuation | 1310nm≤ 0.34dB/km 1383nm≤ 0.34dB/km 1550nm≤ 0.20dB/km 1625nm≤ 0.24dB/km |

Attenuation vs wavelength Max @difference | 1285~1330nm≤ 0.03dB/km 1525~1575nm≤ 0.02dB/km |

Dispersion coefficient | 1285~1340nm≥-3.0ps/nm.km,≤3.0ps/nm.km 1550nm≤18ps/nm.km 1625nm≤22ps/nm.km |

Zero dispersion wavelength | 1312±10nm |

Zero dispersion slope Typical value | ≤0.090ps/nm2.km 0.086ps/nm2.km |

PMD Max individual fiber Link design value(M=20, Q=0.01%) Typical value | ≤0.2 ps/√km ≤0.1ps/√km 0.04ps/√km |

Cable cutoff wavelength | ≤1260nm |

Mode field diameter(MFD) | 1310nm9.2±0.4nm 1550nm10.4±0.5nm |

Effective group index of refraction | 1310nm1.466 1550nm1.467 |

Point discontinuities | 1310≤0.05dB 1550≤0.05dB |

Geometrical characteristics | |

Cladding diameter | 124.8±0.7um |

Cladding non-circularity | ≤0.7% |

Coating diameter | 245±5um |

Coating –cladding concentricity error | ≤12.0um |

Coating non-circularity | ≤6.0% |

Core- cladding concentricity error | ≤0.5um |

Curl (radius) | ≥4m |

Delivery length | 2.1~50.4km/reel |

Environmental characteristics | |

Temperature dependence | ≤0.05dB/km, Induced attenuation at -60~85℃ |

Temperature humidity cycling | ≤0.05dB/km, induced at -10~85℃, 98%rRH |

Watersoak dependence | ≤0.05dB/km, Induced attenuation at 23℃, for 30days |

Damp heat dependence | ≤0.05dB/km, Induced attenuation at 85℃ and 85% RH for 30 days |

Dry heat aging | ≤0.05dB/km, at 85℃ |

Mechanical specification | |

Proof test | ≥9.0N, ≥1.0%, ≥100kpsi,offline |

Macro bend induced attenuation 1 turn around a mandrel of 32mm diameter 100 turn around a mandrel of 50mm diameter 100 turn around a mandrel of 60mm diameter | 1550nm≤0.05dB 1310/1550nm≤0.05dB 1625nm≤0.05dB |

Coating strip force | 1.7Ntypical average force ≥1.3N,≤8.9N peak force |

Dynamic stress corrosion susceptibility | ≥20 |