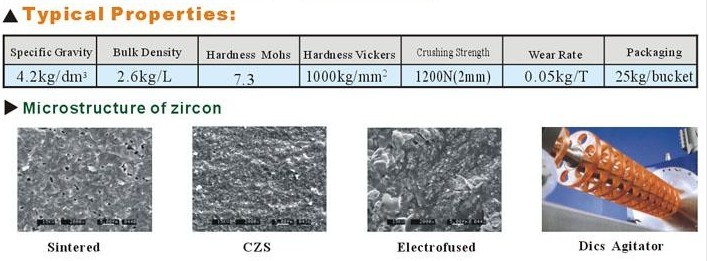

CZS Zirconium Silicate Beads

group nameGrinding Beads

-

Min Order1 piece

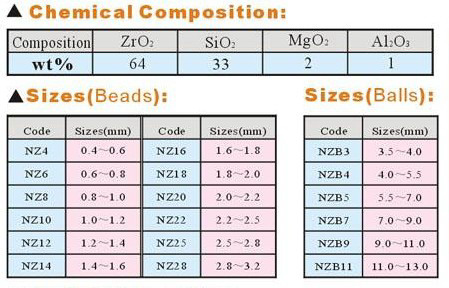

modelCZS-64

payment methodL/C, D/P, T/T, Western Union

-

update timeThu, 26 Sep 2013 10:17:54 GMT

Paramtents

ZrO2 composition 64%

Packging & Delivery

Min Order1 piece

Briefing

Detailed

Features:

☆High crushing strength: Homogenous micro structure ~ Lower bead wear;

☆Higher gravity: Special composition ~ Higher density ~ Higher efficiency.

☆High sphericity: 96% sphericity ~ Better fluid ~ Higher through put;

☆No air pockets: Free from fragile beads ~ Easy change colors;

☆Smooth surface: Deeply polished surface ~ Easy wash; lower wear of contacted parts of mills;

☆Narrow sieving: 0.1mm tolerance ~ Lower bead wear; narrower distribution particles of grinded material.

You need a product

You May Like

- Nearest port for product export

- Ningbo

- Delivery clauses under the trade mode

- FOB, CFR, CIF, EXW, CIP, DDP, Express Delivery

- Acceptable payment methods

- T/T, L/C, PayPal

- Export mode

- Have the independent export and import right