Gypsum Molding Silicone/Silicon

- US $8.89

200 - 40,000 kilogram

- US $6.89

40,001 - 999,999 kilogram

group nameRTV-2 silicone rubber for molds making

-

Min Order200 kilogram

brand nameHong Ye silicone rubber

modelHY628# silicone rubber

payment methodT/T, L/C, Westem Union

-

update timeTue, 05 Nov 2013 11:59:04 GMT

Paramtents

feature 1 good price

feature 2 high quality

feature 3 good tension

Packging & Delivery

Min Order200 kilogram

Briefing

Detailed

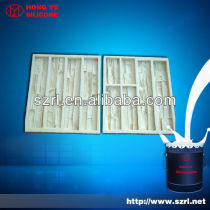

Gypsum Molding Silicone/Silicon application:

Gypsum Molding Silicone/Silicon that can be cure under room temperature. silicone rubber mainly used for the manufacturer of products made of unsaturated resin, epoxy resin, polyurethane, etc.

Gypsum Molding Silicone/Silicon application features:

Gypsum Molding Silicone/Silicon is mainly with the advantages of good tensile strength, high tear strength, high temperature resistance, high duplication times and repeated use, etc. silicone rubber(HY-638) is the most suitable for small products or fine and precision products which is difficult to demould. This silicone rubber is one of the products with the highest use level in the production of craftwork gifts and the shrinkage less than 0.2%.

Gypsum Molding Silicone/Silicon instruction:

1. Adding curing agent 1%, the silicone can still be operated within 2.5 hours and can be

demoulded after 6-8 hours.

2. Adding curing agent 2%, the silicone can still be operated within 50 minutes to 1 hour and

can be demoulded after 2-3 hours.

3. Adding curing agent 3%, the silicone can still be operated within 28 - 30 minutes and can

be demoulded after 1.5-2 hours.

4. Adding curing agent 4%, the silicone can still be operated within 10 - 15 minutes and can

be demoulded after 1 -1.5 hours.

Frequently asked questions of Gypsum Molding Silicone/Silicon

Why does the silicone rubber mold have few molding times?

The silicone rubber mold has few molding times is due to follwoing reasons: adding too much silicone oil which will destroy the molecular of silicone rubber; making the mold for small and fine detailed products with higher hardness silicone rubber which is easy to break; making the mold for large products with soft silicone rubber which will reduce the tensile and tear strength of the mold, and the mold will have deformation. Thus, we should take the proper silicone rubber to make the mold for suitable products.

The infomration just for reference,need more information about Gypsum Molding Silicone/Silicon, please feel free to contact with Ms. Judy at the number of 0086-18938867591 or QQ: 18938867591 Skype: judy.zhao723

Thank you for your attention~

Ms. Judy

You need a product

You May Like

- Nearest port for product export

- Shenzhen, Guangzhou, Xiamen, Shanghai

- Delivery clauses under the trade mode

- FOB, CFR, CIF

- Acceptable payment methods

- T/T, L/C, Westem Union

- Export mode

- Export through agents