Molding Rubber Silicone for Stone Product

- US $9.89

200 - 40,000 kilogram

- US $6.89

40,001 - 999,999 kilogram

group nameRTV-2 silicone rubber for molds making

-

Min Order200 kilogram

brand nameHong Ye silicone rubber

modelHY630 E630

payment methodT/T, L/C, Westem Union

-

update timeFri, 08 Nov 2013 16:11:36 GMT

Paramtents

color as request

catalyst free

sample available

mix ratio 100:3 or 1:1

hardness 10-40 shore A

shelf 12 months

package 25kg and 200kg per drum

Certification ROHS.MSDS.SGS ISO9001:2000

operation pouring and brushing

MOQ 200kgs

Packging & Delivery

Min Order200 kilogram

Briefing

2. Ligh viscosity and good flowability

3. Low shrinkage

4. Favorable tension

Detailed

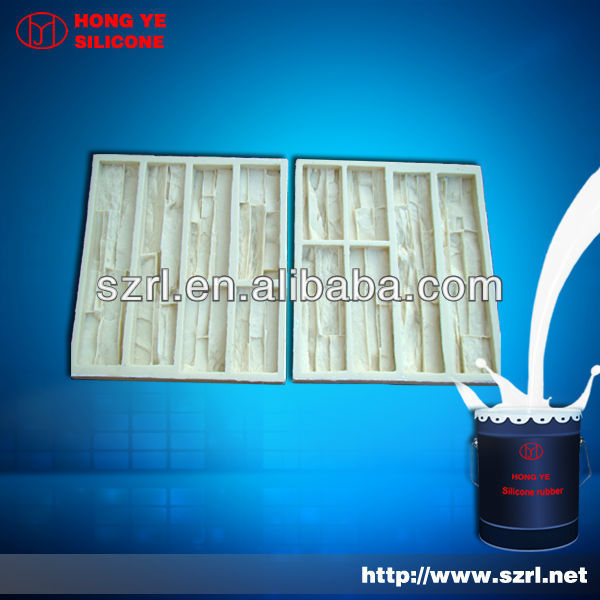

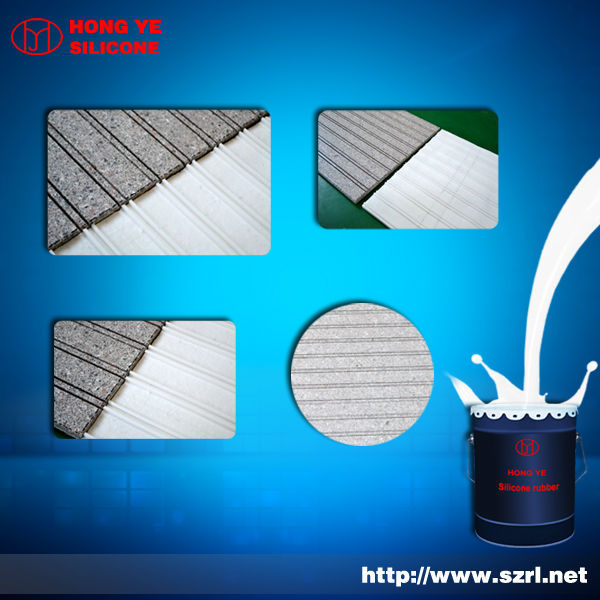

Molding Rubber Silicone for Stone Product application:

Modling silicone can be used for production of different sizes of polyurethane moulds,gypsum moulds,plaster moulds, resin moulds,polyresin moulds,PU resin moulds,wax moulds,stone moulds ,epoxy moulds,acrylic moulds,polyester moulds making

A. Decorative items: cornices moulding ,columns moulding,ornaments moulding,statues molding.....

B. Casting of funiture and decoration crafts molding

C. Construction: prefabrication of decrative features molding,pavement molding,paving stone moulding,urban

furniture molding,concrete products molding

D. Soap moulding,candles crafts moulding,toys moulding,sculpture moulding

Molding Rubber Silicone for Stone Product main features:

1. Good characteristics of easy-operation

2. Light viscosity and good flowability

3. Low shrinkage

4. Excellent tensile and tear strength

5. Favorable hardness

6. High temperature resistance, acid and alkali-resistance and ageing resistance

7. High duplication times

Molding Rubber Silicone for Stone Product frequently asked question:

Why does the silicone rubber molds appeared striately and unsmoothly?

It is because the appearance of the product or the model itself is not perfect, and it has not been polished before the further operation. So when you make silicon molds, firstly you should polish the product, spray the mold spray evenly on the product. In this case, the problem can be avoided.

To recommend suitable product for your application, we would be much appreciated to have your following information:

1. What is the material of your product?

2. What is the size of your product?

3. How do you make silicone mold, by pouring or brushing?

silicone rubber package details

silicone rubber certifications:

SGS

ROSHS

FDA

ISO900

Any questions of Molding Rubber Silicone for Stone Product, please feel free to contact Kaimi:

MOBILE:0086-18938867528

E-MAIL: hyju(at)szrl(dot)net

skype:hyjiangying

You need a product

Related Searches

You May Like

- Nearest port for product export

- Shenzhen, Guangzhou, Xiamen, Shanghai

- Delivery clauses under the trade mode

- FOB, CFR, CIF

- Acceptable payment methods

- T/T, L/C, Westem Union

- Export mode

- Export through agents