Addition Cure Silicone Rubber for Rapid Prototyping

- US $14.00

200 - 40,000 kilogram

- US $9.50

40,001 - 999,999 kilogram

group nameAddition cure silicone rubber

-

Min Order200 kilogram

brand nameHong Ye silicone rubber

modelHY E642 silicone rubber

payment methodT/T, L/C, Westem Union

-

update timeFri, 08 Nov 2013 18:58:24 GMT

Paramtents

Color Transparent

Certificate FDA, RoHS , Reach , ISO

Package Vacuum Pumping

Shelf Life 12 months

Application For molds making

Delivery Within 3 days after payment

Payment terms T/T, L/C

MOQ 200 kg

Operation way Brushing, pouring

Hardness 40 Shore A

Packging & Delivery

Min Order200 kilogram

Briefing

1. High Transparency; High tear and tensile strength

2 Long shelf life with low shrinkage

Detailed

HY- E642 Addition Molding Silicone

Description of Addition Cure Silicone Rubber for Rapid Prototyping:

HY- E series addition molding silicone is generally named two-components silicone rubber, Part A and part B. It features an exceptional fluidity and good operability. The mixing ratio is 1:1 (10:1),mainly be suitable for making molds application.

Applicationsof Addition Cure Silicone Rubber for Rapid Prototyping:

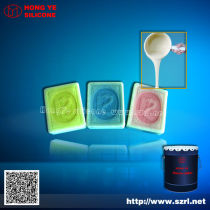

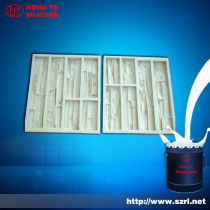

HY- E series addition molding silicone could be mainly used for making concrete stones, wax molds, PU molds, resin molds, gypsum casting, candle molding and chocolate , candy and any other FDA food product mold making,prototyping etc.

Advantages of Addition Cure Silicone Rubber for Rapid Prototyping:

*low shrinkage (less than 0.1% )

*high tensile and tear strength with high copy times

*easy for operation (mixing ratio at 1:1 /10:1)

*very good flow and easy for pouring operation

*Fast and non-shrink cure at room temperature which can be accelerated considerably by the application of heat

*Outstanding resistance to concrete

Technique Data Sheet of HY-E642 addition cure silicone for rapid prototyping:

Product | E-642 |

Appearance | Translucent |

Hardness(shore A) | 30±2 |

Mix ratio(A:B) | 1:1/10:1 |

Viscocity Part A(mPa.s) | 23000±2000 |

Viscocity Part B(mPa.s) | 3500±500 |

Tensile strength (kgf/cm2) | 45±5 |

Tear-strength (kN/m) | 20±2 |

Elongation(%) | 500±50 |

Pot life/working time (mins) | 30-40 |

Curing time/setting time (hrs) | 3-4hrs(25°C) 110-20mins(60°C) |

Shrinkage rate (%) | 0.1 |

(Note: Other hardness is adjustable)

Operation instruction of HY-E Series molding silicone for rapid prototyping:

1. Pls clear the model and tool totally before operation to prevent cure inhibition.

2.Weigh the two part correctly by electronic weight in two separate container .

3. Mixing the two part in 1:1/10:1 and stir part A and part B evenly in 2-3 minutes .

4.And get the mixture for vacuum-pumping for de-air the bubble in around 2-3 minutes . (If there is no vacuum machine, pls pour the mixture carefully and slowly down the side of the mold frame so that less bubbles caused)

5. Enclose the product (the original model) with four plastic plates or wooden plates.

6. Clean your products and brush a layer of release agent(detergent or soap water) on your product.

7. Pour the vacuumed mixture into the model frame from the side of the mold frame.

Warm Tips for Rapid Prototyping of Silicone Rubber:

As our E-series silicone is platinum cure silicone , which is very easy to cause cure inhibition , so pls do remember thoroughly clean the model and tool before operation . Besides , pls avoid the liquid E-series silicone contact or mix with the following material , otherwise the silicone won’t be cured:

1. Liquid condensation silicone ( condensation silicone not completely cured or organic tin compounds )

2 .Sulphur, sulfide and sulfur rubber materials.

3. Amine compounds as well as contains the amine materials.

4 .Pewter solder flux.

Shelf Life of Silicone Rubber for Rapid Prototyping:

8-10 months when stored under 24°C in original unopened packages.

Package of Silicone Rubber for Rapid Prototyping:

If ratio is 1:1 :Packed in 20kg/pail + 20kg/pail and 200kg/pail + 200kg/pail.

If ratio is 10:1 :Packed in 20kg/pail + 2kg/pail and 200kg/pail + 20kg/pail.

Any more information , please feel free to contact Ms Cecilia

Office No.: 086-0755-89311348

Fax No.: 086-0755-89948030

Mob: 86-18938867615

Skype: summertaoteng

Email: hyyi(at)szrl.net

Website: ..........net

You need a product

You May Like

- Nearest port for product export

- Shenzhen, Guangzhou, Xiamen, Shanghai

- Delivery clauses under the trade mode

- FOB, CFR, CIF

- Acceptable payment methods

- T/T, L/C, Westem Union

- Export mode

- Export through agents