liquid Encapsulant and Potting silicone for pcb board

- US $13.92

100 - 40,000 kilogram

- US $5.58

40,001 - 999,999 kilogram

group nameelectronic potting silicone rubber

-

Min Order100 kilogram

brand nameHong Ye silicone rubber

modelHY210

payment methodT/T, L/C, Westem Union

-

update timeFri, 08 Nov 2013 19:23:53 GMT

Paramtents

mixing ratio 10:1 or 1:1

color clear or yellowish

HS code 39100000

MOQ 100kgs

certificant Rohs,SGS

Brand Hong Ye Silicone rubber

Packging & Delivery

Min Order100 kilogram

Briefing

Easy operation

Nontoxic and durable

waterproof

low linear shrinkage

Detailed

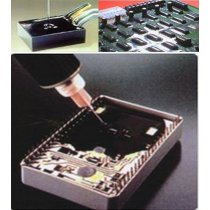

Encapsulant and Potting silicone Description:

It can be vulcanized under room temperature or high temperature with low viscosity, easy mixing and pouring, and it is applicable to bulk pouring with excellent electrical performance. It is applicable to sealing, bonding, coating for electronic parts.

Encapsulant and Potting silicone Rubber Applications:

It serves sticky viscosity, low shrinkage and non-corrosiveness. It can be used for a long time under the temperature of -60~200C with the characteristics of moisture-proof and waterproof, radiation-proof, as well as weatherable and anti-ageing. It is applicable to sealing, bonding and coating for electronic parts.

Features of Encapsulant and Potting silicone:

1 Low viscosity,good flowable,light weight

2 No need primer for some kinds of materials

3 Excellent heat and cold resistance,It can operate from -50 C to 180 C .

4 Excellent weather resistance , acid and alkali , salt spray resistance , ozone resistance and resistance to chemical erosion resistance .

5 Excellent electrical insulation .

6 Removable , sealed components can be removed to replace , re - filling plastic repair without leaving any traces

7 RoHS and REACH certificate

Using instruction of Encapsulant and Potting silicone

1. First stir the Part A completely before using(to be sure the segiment is evenly mixted) to mixing the Part B as Part A.

2. Mix the Part A and Part B completely according to the mix ratio(10:1by weight) and can be used after deaired

3.this product can be vulcanized at room temperature. After basic curing then go to the next step.Full curing process will be within 24h.The enviromental temperature, especially the humidity, will affect the curing time greatly. Customers should make appropriate adjustments acording to local conditions. The mixed silicone should be finished at one time to avoid any waste of material.

Encapsulant and Potting silicone Notes:

1.The following material may hinder the curing of HY 9055, So pls use after the test. When necessary, pls clean the application areas.

Organotin compound or Condensation silicone with organotin

Sulphur, sulfide and sulfur rubber materials.

Amine compounds as well as contains the amine materials.

Pewters solder flux

2. HY 9055 Encapsulant and Potting silicone should be sealed storage.The mixture should be used up disposably to avoid causing waste.

3. HY 9055 belongs to non-dangerous goods, but keep away from mouth and eyes.

4. When it gets stratified after a period of storage, Please mix it evenly before using,which does not affect the performance.

Any questions of Encapsulant and Potting silicone,please feel free to contact Ms Cassi

TEL: 086-755-89948006

Cellphone: 0086-15220073603

You need a product

Related Searches

You May Like

- Nearest port for product export

- Shenzhen, Guangzhou, Xiamen, Shanghai

- Delivery clauses under the trade mode

- FOB, CFR, CIF

- Acceptable payment methods

- T/T, L/C, Westem Union

- Export mode

- Export through agents