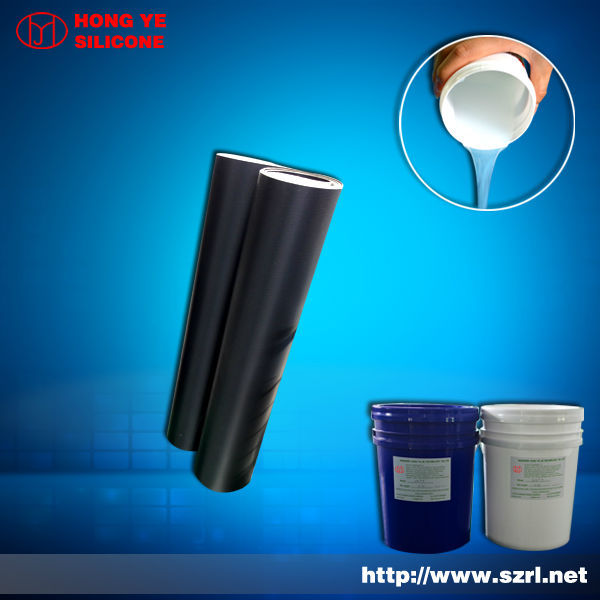

Addition cure silicone rubber for screen printing Ink

- US $15.88

200 - 40,000 kilogram

- US $12.88

40,001 - 999,999 kilogram

group namesilicone rubber for textile coating& trademarks

-

Min Order200 kilogram

brand nameHong Ye silicone rubber

modelTB0330# silicone rubber

payment methodT/T, L/C, Westem Union

-

update timeFri, 08 Nov 2013 22:31:03 GMT

Paramtents

color transparent

Mixing ratio 1:1 10:1

MOQ 200KG

Sample Available

Payment T/T L/C Western union

Package 25kg/drum 200kg/drum

Features Liquid

HS Code 39100000

Port shenzhen

Packging & Delivery

Min Order200 kilogram

Briefing

exceptional fluidity

good quality

Low shrankage

MSDS FDA

Detailed

Addition cure silicone rubber for screen printing Ink

Packaging & Delivery

| Packaging Detail: | 1kg 5kg 25kg 200kg or wood case as per your requirement |

| Delivery Detail: | 3-5 day after you confirm your order |

Specifications

1.printing with swith silicone rubber products

2.Superior Elongation

3.No Harm to Human body

4.Superior Chemical resistance

Place of Origin: Guangdong China (Mainland) | Brand Name: Hong Ye Silicone Rubber | Model Number: Silicone rubber TB0330 |

color: Any | Viscosity: low | Tensile Strength: strong |

tear strength: High | Size stability: good | reproduction times: high |

elongation: high | Linear shrinkage rate: low | anti-scar: -50-180°C |

Stripping the gender: good |

|

|

How to use Addition cure silicone rubber for screen printing Ink

1. The cast pouring, for example:

Prepare a frame, fix the prototype for copy into the frame, (if the prototype’s material is glass or ceramic, the release agent is necessary to prevent sticking.

2. Take 2~3%curing agent of RTV, and mix it evenly with rubber.

3. Vacuum deforming in 1~3 min, inject the rubber into the type box, then vacuum deforming again, curing 24 hours in nature room temperature, use it after demand.

4. Detmold after 3 hours’ room temperature curing, and then use it after 24 hours’ keep mold under the same condition

(Note: our company does not recommend you to add silicone oil. If a special soft silicone mold or fine detailed and complex patterns products are required, 5%-10% silicone oil can be added to soften the mold for easy demold.)

Silicone ink for Characteristic:

Easy and simply operation 10A:1B with normal printing process

Catalyzed by platinum, no toxicity and non-corrosiveness

No solvent or cured by products

Non pollution environment, environment friendly silicone ink,

Non harm to human body. caused by the organic solvent into environment friendly, in noxious ink

Non cause environmental problems when test and destroy ester of silicone ink.

Silicon Ink with SGS approval, the silicone ink based on safety design easily pass any international inspection

Cured silicone in with high elastic, soft smooth hand feeling when touch, slippery, high stretchable and non bleeding

adhered on textile fiber well after being cured and forms elastomeric of silicone .

good ink for silicone rubber products and latex with great adhesive.

Produce high tear strength, create high quality printing effect.

moderate fluidity and cure time application. Easy process

Low and higher temperature resistance(-50 to 300)

More informaiton,please feel free to contactions Christy:

TEL: 086-755-89948006

FAX: 086-755-89948030

MOBILE: 086-18938867547

EMAIL:hyxj(at)szrl(dot)net

You need a product

You May Like

- Nearest port for product export

- Shenzhen, Guangzhou, Xiamen, Shanghai

- Delivery clauses under the trade mode

- FOB, CFR, CIF

- Acceptable payment methods

- T/T, L/C, Westem Union

- Export mode

- Export through agents