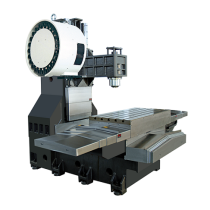

VMC1890L Vertical Machining Center

group nameVERTICAL MACHINING CENTER

-

Min Order1 piece

brand nameSINO CNC MACHINERY

modelVMC1890L

payment methodL/C, T/T, Western Union, MoneyGram

-

update timeMon, 26 Nov 2018 15:41:31 GMT

Packging & Delivery

Size500cm x 500cm x 410cm

Weight16000.00kg / piece

Min Order1 piece

Briefing

Detailed

Product Overview

Machine Characteristics

Machine Parameter

CODE | ITEM | DETAILS | |

1 | WORKTABLE(WIDTH×LENGTH) | mm | 900×2000 |

2 | T SLOTS | mm | 5-22 |

3 | DISTANCE BETWEEN T SLOTS | mm | 165 |

4 | MAX.LOAD BEARING OF WORKTABLE | kg | 1200 |

TRAVEL | |||

5 | X AXIS | mm | 1800 |

6 | Y AXIS | mm | 900 |

7 | Z AXIS | mm | 800 |

8 | DISTANCE FROM COLUM TO SPINDLE CENTER | mm | 960 |

9 | DISTANCE FROM TABLE TOP SURFACE TO SPINDLE NOSE | mm | 180-980 |

SPINDLE | |||

10 | SPINDLE HOLE TAPER | BT50 | |

11 | SPINDLE SPEED RANGE | r/min | 20-4500 |

12 | SPINDLE POWER | kw | 19.9 |

13 | SPINDLE TRANSIMISSION | BELT | |

14 | SPINDLE PART DYNAMIC BALANCE TYPE | G1 | |

15 | SPINDLE ACCURACY | SPINDLE FACE RUNOUT::0.005mm | |

SPINDLE RADIAL RUNOUT :NEAR-END 0.007mm | |||

TOOLS HOLDER SIZE | |||

16 | TOOLS HOLDER STANDARD | MSA403 BT50 | |

17 | RIVET STANDARD | MSA403 P50T-1 | |

FEED | |||

18 | X/Y FEED RATE | m/min | 20/20 |

19 | Z FEED RATE | m/min | 15 |

20 | CUTTING FEED SPEED | mm/min | 0-15000 |

TOOLS MAGAZINE | |||

21 | TOOLS MAGAZINE MODEL | MANIPULATOR | |

22 | CAPACITY | PCS | 24 |

23 | FULL TOOLS MAX TOOL DIAMETER | mm | Ф112 |

24 | NEIGHBOR EMPTY TOOL DIAMETER | mm | Ф200 |

25 | MAX.TOOLS ALLOWABLE WEIGHT | kg | 18 |

26 | MAX.TOOLS ALLOWABLE LENGTH | mm | 300 |

27 | TOOL CHANGE TIME | s | 5 |

28 | TOOL CHANGE WAY | FORWARD/REVERSAL | |

POWER SOURCE | |||

29 | MACHINE ELECTRIC CAPACITY | KVA | 30 |

30 | COOLING PUMP FLOW RATE | L/min | 60 |

31 | MACHINE COMPRESSED AIR | kg | 5~6 |

32 | POWER REQUIREMENT | 380V±10% 50Hz | |

ENVIRONMENTAL REQUIREMENT | |||

33 | ENVIRONMENTAL TEMPERATURE REQUIREMENT | 0℃~40℃ | |

34 | RELATIVE HUMIDITY | 20%~80% | |

MACHINE SIZE | |||

35 | MACHINE DIMENSION | mm | 5500×3700×4100 |

36 | MACHINE WEIGHT | kg | 16000 |

37 | MACHINE SHIELD | FULL PROTECT | |

ACCURACY | |||

38 | X/Y/Z POSITION ACCURACY | mm | ±0.012 |

39 | X/Y/Z RE-POSITION ACCURACY | mm | ±0.008 |

You need a product

You May Like

- Nearest port for product export

- SHANGHAI, NINGBO

- Delivery clauses under the trade mode

- FOB, CFR, CIF, EXW

- Acceptable payment methods

- T/T, L/C

- Export mode

- Have the independent export and import right