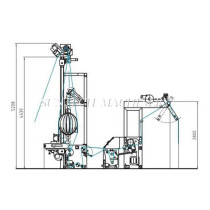

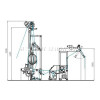

SUNTECH Evolution type for raw and wet fabrics tubular slitting machine

- US $4000.0

1 - 5 piece

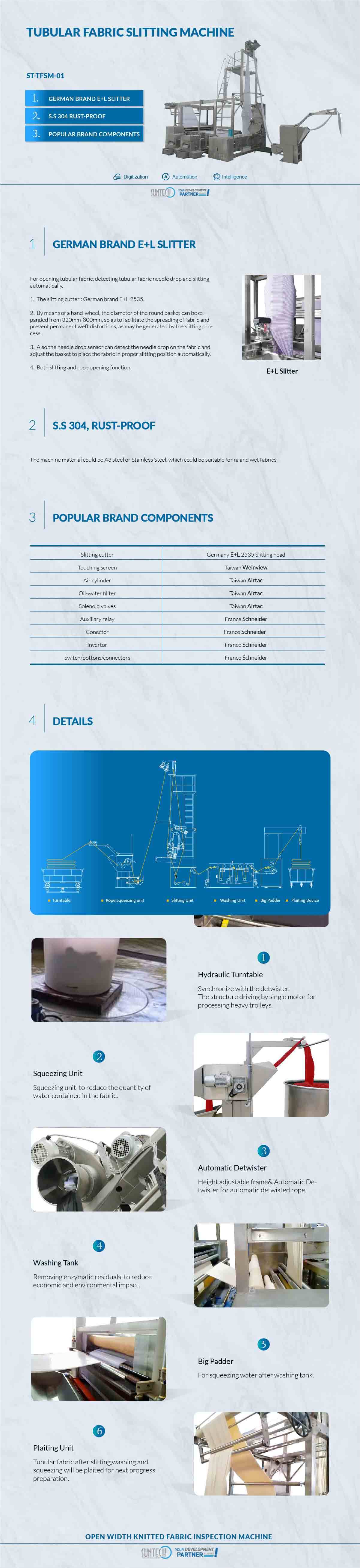

group nameRope Opener Tubular Slitter

-

Min Order1 piece

brand nameSuntech

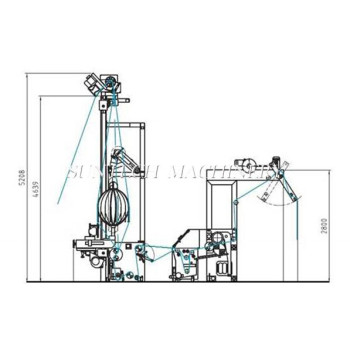

modelST-TFSM-01

payment methodL/C, T/T, Western Union

-

update timeThu, 07 May 2020 17:49:27 GMT

Paramtents

Condition New

Voltage 3phase-380V; 50HZ(can be adjusted to suit for different countries)

Power(W) Special Model

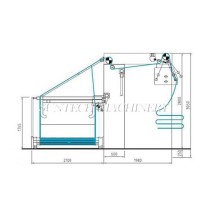

Dimension(L*W*H) As per different models

Weight Per model

Certification ISO,CE

Warranty 13 months

After-sales Service Provided Engineers available to service machinery overseas

Item Knitting Rope Opener and Slitting Machine For Textile Industry

Speed: 0-80m/min

Packging & Delivery

Min Order1 piece

Briefing

Detailed

You need a product

You May Like

- Nearest port for product export

- Ningbo, Shanghai

- Delivery clauses under the trade mode

- FOB, CFR, CIF, EXW, Express Delivery

- Acceptable payment methods

- T/T, L/C

- Export mode

- Export through agents