SLJ series high-safety and energy efficient hot air circulation dipping paint electric drying oven

group nameThe fuel/gas heating drying oven

-

Min Order1 piece

brand nameLary

modelSLB series

payment methodT/T

-

update timeSat, 06 Dec 2025 10:22:42 GMT

Paramtents

Product name drying oven

Other name dipping paint drying oven

Application electric motor, stator, transformer, coil, electri

Working temp. 250℃

Temp. fluctuation ≤±1℃

Heating power 37.5-54KW

Material of Muffle Stainless steel or ceramic or Customized

Control chamber Customized

Temperature Uniformity ≤±2.5%

Environment of oven Hot air circulation

Packging & Delivery

Min Order1 piece

Briefing

Detailed

SLB seriestransformer curing oven

Keywords:electric drying oven, spray paint drying oven, dipping paint drying oven, coil drying oven, hot air circulationdrying oven, drying oven for stator

Productattributes:Productname: drying oven

Other name: dipping paint drying oven

Application: electric motor, stator,transformer, coil, electrical products

Working temp.:250℃

Temp. fluctuation:≤±1℃

Heating power:37.5-54KW

Control chamber:Customized

Temperature Uniformity:≤±2.5%

Environment of oven: Hot air circulation

Chamber size:Customized

Pictures:

Features:

1) Adopts our unique design of heatexchanger which will make high thermal efficiency, and low temperature of the emissions .

2)Sensitive and reliable thermostatic control system and over temperature alarmsystem.

3)Over pressure protection system. When the wind pressure (the gas exhausting) isabnormal, it will give out sound and light alarms and cut off heating power toensure the safety of equipment.

4)Complete circulating ventilation and unique heated-air circulation systemensure the temperature rises evenly. Large ventilation rate during the wholecourse and unique pre-posed ventilation function guarantee that combustible gasconcentration in the oven is always within safety limits.

5)Because of large and efficient ventilation, the concentration of steam ofdissolvent in the working chamber is always low, which accelerates thevolatilization of dissolvent in the insulating paint of dried products. Thus,drying duration is shortened. It not only raises efficiency but also savesenergy.

6)Heating element adopts electric heating tube with low surface temperature,which eliminates the most dangerous factor that triggers explosion.

7)There is a pressure outlet in large area on the top of the oven, which cutsdown losses as possible in case of accident.

8)Insulation resistance tester can measure at any time.

9)Trolley is for loading work pieces. Manual type and power-driven type areoptional.

Specification:

model | Chamber size(mm) (W×D×H) | Working temp(℃) | Temp uniformity(%) | Temp fluctuation(℃) | Heating power(kW) |

SLJ-1 | 1800×2000×1700 | 250 | ≤±2.5 | ≤±1 | 37.5 |

SLJ-2 | 1800×2000×2000 | 40 | |||

SLJ-3 | 1800×2600×1700 | 45 | |||

SLJ-4 | 1800×2600×1700 | 51 | |||

SLJ-5 | 1800×3000×2000 | 54 |

Application:

SLJ series high-safety and energy efficient dipping paintdrying oven (also known as electric motor dipping paint oven , electric motordipping paint drying oven or far infrared rotation oven) is widely used in thedrying process of impregnated products, such as electric motor, stator,transformer, coil, electrical products. Also, it can be used in the dryingprocess of paint coating and the drying, curing, heat treatment, disinfectionand heat preservation of normal articles. The oven is equipped with waste gasoutlet which is convenient for exhausting of gas. It adopts low surface loadingsealed electric heater. On the top, there is an explosion venting to protectexplosion effectively. The oven is adequate for drying and curing which needsstrict temperature requirement under the condition of large ventilation rate.

Factory:

Company:

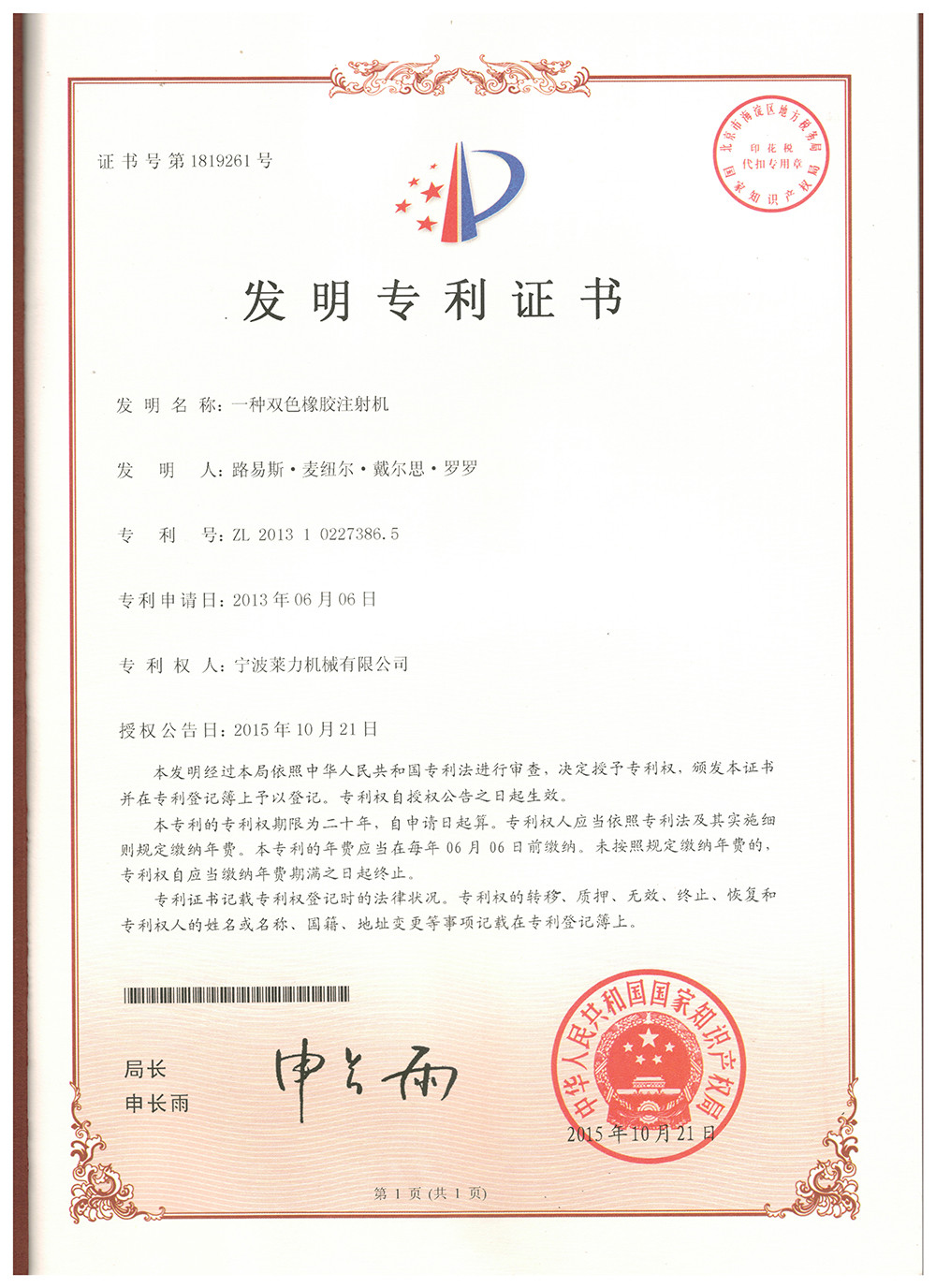

Ningbo Lary Industry Technology Co., Ltd is ajoint venture with Portugal TECNIROLO Engenharia Industrial S.A. Lary is anengineering & manufacturing enterprise which inherits the concept ofproviding customers with best services in Europe for more than twenty years. TecniRolo - Portugal andLary Industry - China are a group of companies that work as a global solutionprovider for an international network over of 16 countries.

Certification:

Customers:

Paymentsand Delivering:

Payments: 40% depositby T/T after confirming thedrawings and 60% balance by T/T before delivery.

Delivering: 90 -120 daysafter we confirmed both side.

Contactus:

Amy Ren

Ningbo Lary IndustryTechnology Co., Ltd.

Ningbo

Add: No.9 East ofJingu middle Road, Yinzhou District, Ningbo City, China

Web: www.larytec.com

Tel:0086-754-88033926

Fax:0086-754-88137126

Mob: 0086-13958255267

Email:amy..........com

Welcome to visit us!

You need a product

You May Like

- Nearest port for product export

- Ningbo, Shanghai

- Delivery clauses under the trade mode

- FOB

- Acceptable payment methods

- T/T, L/C, PayPal