SWC-720 Automatic Flow Wrapper Packaging Machine

group nameHorizontal Flow Packing Machine(normal type)

-

Min Order1 piece

brand nameSANWEIHE

modelSWC-720

payment methodL/C, T/T

-

update timeTue, 15 Sep 2020 13:52:48 GMT

Paramtents

color silver and blue

OEM Service available

Packging & Delivery

Weight900kg / piece

Min Order1 piece

Briefing

Detailed

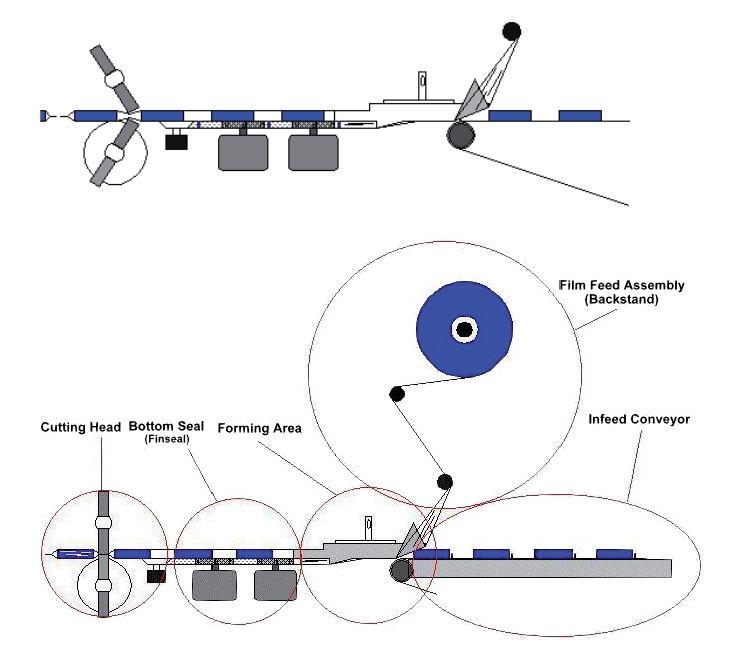

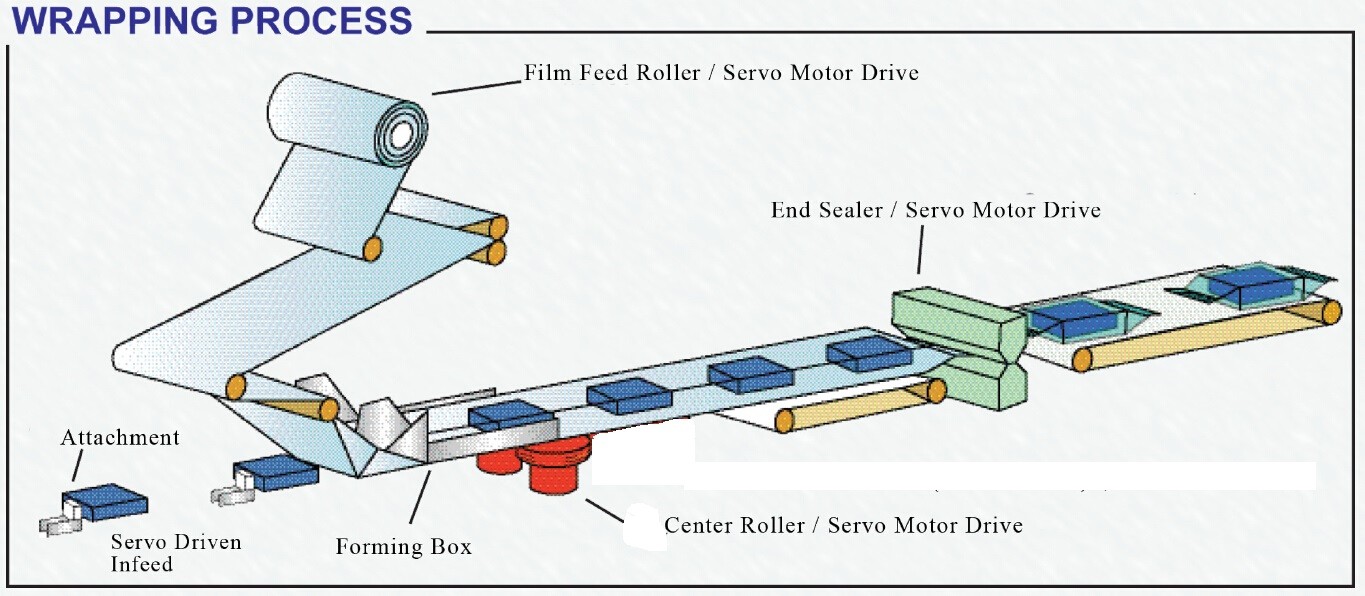

The flow wrap packaging machine packages product by wrapping it in film. The flow wrapper has an infeed conveyor, a film feed assembly, a forming area, a cutting head, and a discharge area. Product is placed on the infeed conveyor. As the infeed conveyor delivers product to the forming area, film is drawn from the film feed assembly into the forming area, where a film tube is formed around the product and a finseal is created. The film tube and the product then are delivered to the cutting head. The cutting head creates the endseals while it cuts apart adjoining wrapped products into individual packages, and delivers the packages to the discharge area. At this time the whole packing process is done.

The drawing below shows a horizontal flow wrap packaging machine:

|

Max width of film |

720mm |

|

Packaging range |

L53~300W20~100 H5~70mm |

|

Packing speed |

30-2200Bag/min |

|

Category of film |

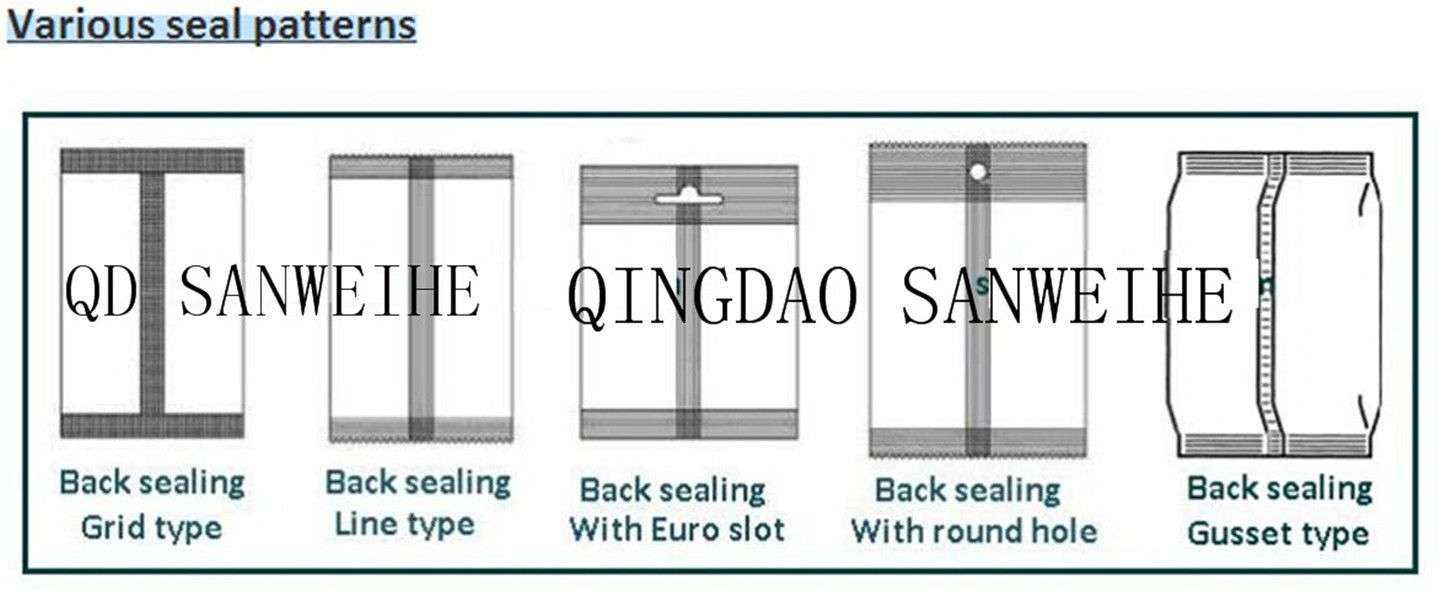

Heat-melt-cut sealing film like PAPER/PE, OPP/PE, OPP/AL/PE, CPP/PE |

Power of main motor | 1.5KW |

Power of electrical | 2.5KW |

Total power | 4.6KW single phase 220V |

Overall dimension L×W×H | 5700×1050mm×1700mm |

Weight | About 1000kg |

Auxiliary equipment

1.Date code printer

2.Automatic feeder

1. We are manufacture but not trade company

2. We have professional staff who can advise you the suitable choice for your specific need

3. Our professional workers will make the perfect product for you

4. Well trained and experienced staff will answer your inquiry timely

5. We provide competitive price and fine quality products

You need a product

You May Like

- Nearest port for product export

- QINGDAO, TIANJIN, GUANGZHOU

- Delivery clauses under the trade mode

- FOB, CFR, CIF, EXW

- Acceptable payment methods

- T/T