Highway Guardrail Roll Forming Machine

group nameRoof Roll Forming Machine

-

Min Order1 set

brand nameJunnan Steel Wholesale

payment methodL/C, D/P, Western Union, T/T, Paypal

-

update timeThu, 29 Jan 2026 20:02:58 GMT

Paramtents

Hydraulic Group 22 KW

Cutting tool material Cr12MOV

Control Voltage 24V

MOQ 1 set

Packging & Delivery

Weight18000kg / set

Min Order1 set

Briefing

1.Beautiful appearance2.Accuracy profile3.Easy operation, low maintenance cost

Detailed

Highway Guardrail Roll Forming Machine

Machine Parts

1) Highway guardrail roll forming machine feeding and leveling

Feeding motor: 11 KW, Servo Motor.

With Connection platform

A coiling tail and a roll of material is easy to set welding platform

Welding machine is provided by the buyer

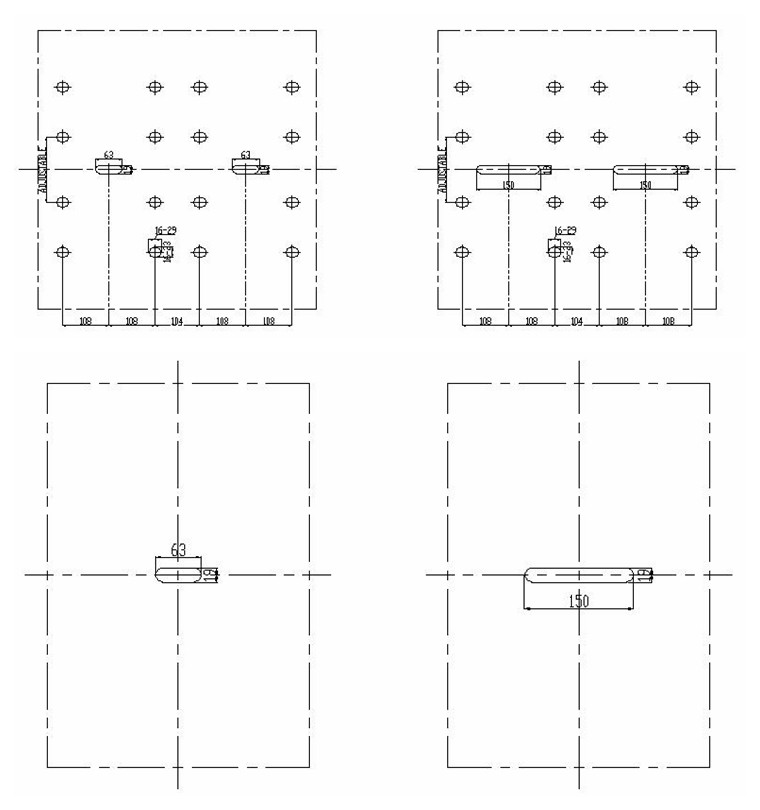

2) Highway guardrail machine hydraulic pre-punching device

The main oil press (200 tons); Two sets of punching mould, changing different die for different mould.

Two sets of punching mould; The material of Punching pin and die: Cr12MOV.

Punching single hole; Two sets of punching mould, changing different die for different mould.

Two sets of punching mould; The material of Punching pin and die: Cr12MoV .Hydraulic Group: 22KW

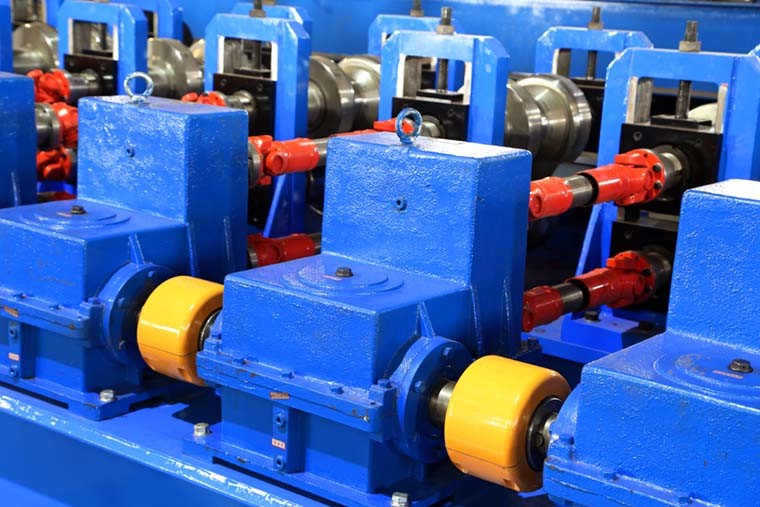

3) Main Highway guardrail roll forming machine

Gear box drive (upper and lower rollers with power) ; Column type structure Design

18-step to form; Designing 16-step and keep 2-step for spare use

Rollers manufactured from Cr12MOV (SKD11), precision machined

Rack using 45# wage steel seal plate, the overall processing

Main Motor=45KW , Frequency speed control

Forming speed: 1pcs per minute based on 4320mm length

Cr12MOV(SKD11)Rollers, Free Standing Structure

45KW Powful Motor

Gearbox Driving

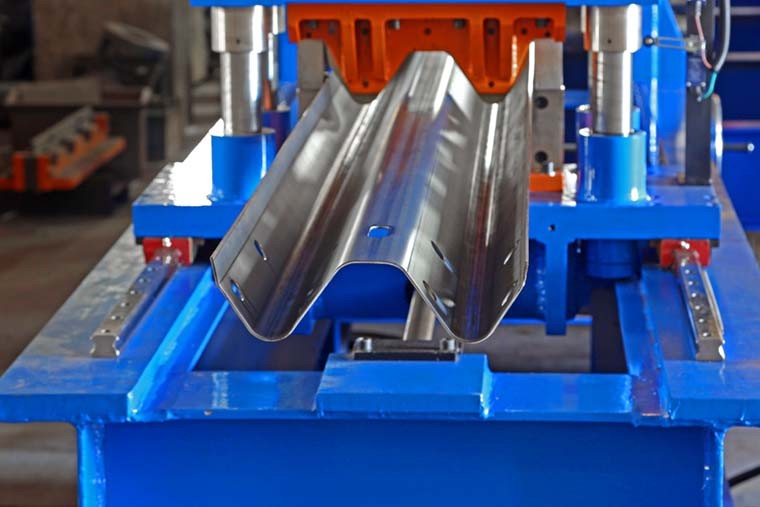

4) highway guardrail roll forming machine post cutter

When producing different length profiles, adjust the distance between the Cutting and punching

To achieve a stop, once the completion of punching and cutting action

Stop to cutting, No blanking cutting

Hydraulic Group: 22 KW; Independent hydraulic station,

Cutting tool material: Cr12MOV

5) Highway guardrail roll forming machine decoiler

Hydraulic system expand coil inner hole, Pump motor: 4KW

Frequency Inverter to regulate turning speed, Motor: 2.2KW

Coil inner–diameter=518±30mm ;Coil outer–diameter=1600mm

Load capacity = Max.10Tons; Coil width = Max.600mm

Pneumatic arm, air supply by the buyer

Other detailes of highway guardrail roll forming machine

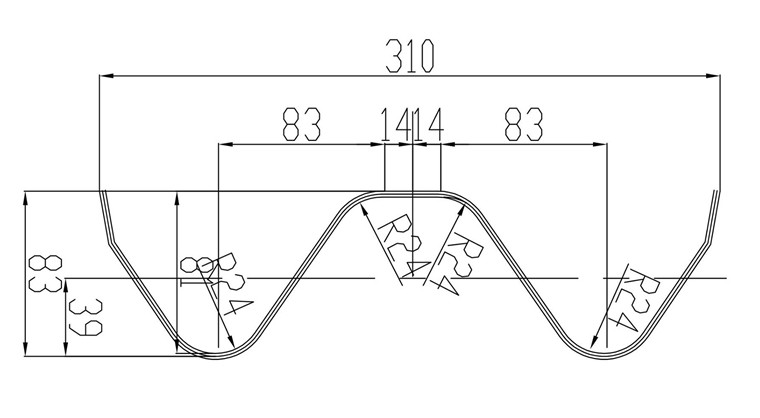

Suitable for material with thickness 2.7- 3.4mm

Shafts manufactured from 45#,Main shaft diameter=φ105mm,precision machined

Motor driving,Gear chain transmission, 16 rollers to form and 4 rollers for straightening and levelling

Main motor=18.5KW , Frequency speed control. Forming speed approx.18m/min

PLC Control System (Touch screen:German Siemens , PLC: German Siemens

Inverter: Finland VOCAN/Taiwan DELTA/ALPHA, Encoder d:Japan Koyo/OMRON)

Combined with: PLC, Inverter, Touch Screen, Encoder, etc

Cut-to-lengthtolerance≤±2 mm

Control Voltage 24V

User's manual in English

You need a product

You May Like

- Nearest port for product export

- Tianjin port, Jingtang port, Caofeidian port, Main port china

- Delivery clauses under the trade mode

- FOB, CFR, CIF, EXW

- Acceptable payment methods

- T/T, L/C, D/P D/A, MoneyGram, Credit Card, PayPal, Westem Union, Cash