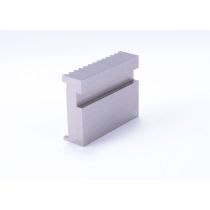

Product Details

1. Material: S45C from HTTACHI Japan. We promise that the materials will be purchased at regular stores and we will provide material proof to each customer.

2. Part Processing : The processing of this product is our factory's most experienced processing technology, surface grinding processing, EDM, wire cutting.

3. Surface treatment: It only involves grinding here. but mirror polishing, pvd coating, dlc coating can be available in our factory.

4. Applied software: Pro/E, Auto CAD 2000,solid work 2001,CAXA,UG,CAD,CAM

5. File Formats:

- 2D-- dxf & dwg & pdf;

- 3D-- UG files: like STP, IGS, X_T., Prt.

6. Equipments: Surface grinders, EDM machines, wire cutting machines.

7. Injection mold part accuracy:

- Lapping accuracy: 0.001 mm

- EDM accuracy: 0.002 mm

- Vertical accuracy: 0.002 mm

Specification About This Injection Mold Part

Specification | According to your requirement. |

Material | Stainless steel, brass, copper, aluminum, iron, high- speed steel, zinc, etc. |

| Surface Treatment | Our surface treatment processes can be divided into the following categories: mirror polishing, PVD coating, DLC coating, etc. |

| Applications | Automotive, electrical equipment, mechanical equipment, mobile and computer connectors, etc. |

| Our features | A company with industry and trade integration |

| Main Products | Precision mold parts: connector mold parts, EDM spare parts, Wire EDM parts, injection mold parts, core pins and sleeves, etc. |

| Producing Equipments | CNC machine ..Other machines including Grinder machines, Wire cutting machines, EDM machines, milling machines, etc. |

| Testing Equipment | 2.5D Projecting , many different styles of height gauge, two dimension, hardness tester, etc. |

| Workforce | A group of experienced production technician, sophisticated engineer and dedicated quality inspection worker. |

| About us | Our company was founded in 2005, specializing in the production of CNC milling parts, grinding parts, EDM parts, wire EDM parts, and other metal parts. Our main production modes are processing based on customers’ drawings or samples. |

| Main Markets | The United States, Japan, Canada, Italy, India, Europe and many other countries and regions |

Packaging & Shipping

- For the packing : usu inner with PE film, plastic box;

- Outer with carton

- For the shipping: we advice you the sea transportation. our port is ShenZhen, China

- If you have other specified demands,contact us