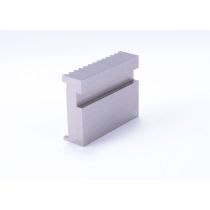

HSS Material OEM Processing Internal- External Lapping Injection Mold Components

Primary Features

1. The Part Surface: The injection mold part shown now has no special toilet surface treatment, because it has reached the requirements of customer's injection mould after it has been processed by internal- external lapping. Of course, if your product is requested in this respect, you can let us know. Here are some kinds of surface treatment for your reference: mirror polishing, pvd coating, dlc coating and more.

2. The Part Material: This part uses the high-speed steel material, we know the requirements of injection mold material is relatively high, such as easy processing, wear resistance and so on, so our processing components as part of the mold, also pays great attention to the choice of materials. High speed steel SKH51 with high wear resistance and toughness is a good choice.

3. Any other material and dimension are determined by customers' demand.

4. The Part Usage: Injection mold part.

5. The Part Manufacturing process: The injection mold parts processing technology has three main steps: the first step, internal - external grinding processing (Lathe machining ) ; second steps, Sadegh discharge processing; third steps, wire cutting.

6. The Part Euipement: lathe machine, internal - external lapping processing, EDM, WEDM and more.

7. The Part Testing equipment: Projector for digital measuring instrument, Switzerland TRIMOS height gages, Japan Nikon height gages, two dimension, hardness meter and more.

8. The Part Tolerance: +/-0.05mm

Special Explanation

We are a custom processing service enterprise in which materials, sizes, colors, processing techniques, packaging and transportation, thses can be customized according to the specific requirements of each customer.

Spcification

A. Processing We Can Supply: CNC milling, EDM, WEDM, Grinding, Internal - external lapping, Lathe machining and more.

B. Matrial We Can Supply: Stainless steel, aluminum , brass , iron , zinc ,alloy steel , carbon steel.

C. Checking

- For each piece of injection mold parts, we always do the following;

- Each process must be checked;

- Every maker will check the parts he is machining;

- The final comprehensive inspection.

D. Delivery: Generally speaking, we need 5-15 working days after you place an order , the speed of delivery depends on the quantity and complexity of the parts. or according to client requirement.

E. Dimension: According to the customers' drawings

F. Injection mold parts color: Black, white, any other colors as per Customers’requirement .

G.Injection mold parts surface: Polishing, pvd coating, dlc coating , etc.

H. Mould life:500,000 shots

I. OEM:Welcom

J. Applications: Automobiles, medical, electrical and so on

K. File format used: Solidworks, Pro/ Engineer, Auto CAD, PDF, JPG ect

L. Hardness: Generally speaking,determined to materials

M. Precision:Grinding :0.001 mm; EDM: 0.002 MM;

Our Packing and Shipping

Packaging Details

HSS Material OEM Processing Internal- External Lapping Injection Mold Components

- Commercial packaging: PE film+ plastic box +carton

- as the clients' requirements

Shipment: By DHL, TNT, Fedex, EMS and more

Delivery Time

Usual circumstances, within 5-15 working days