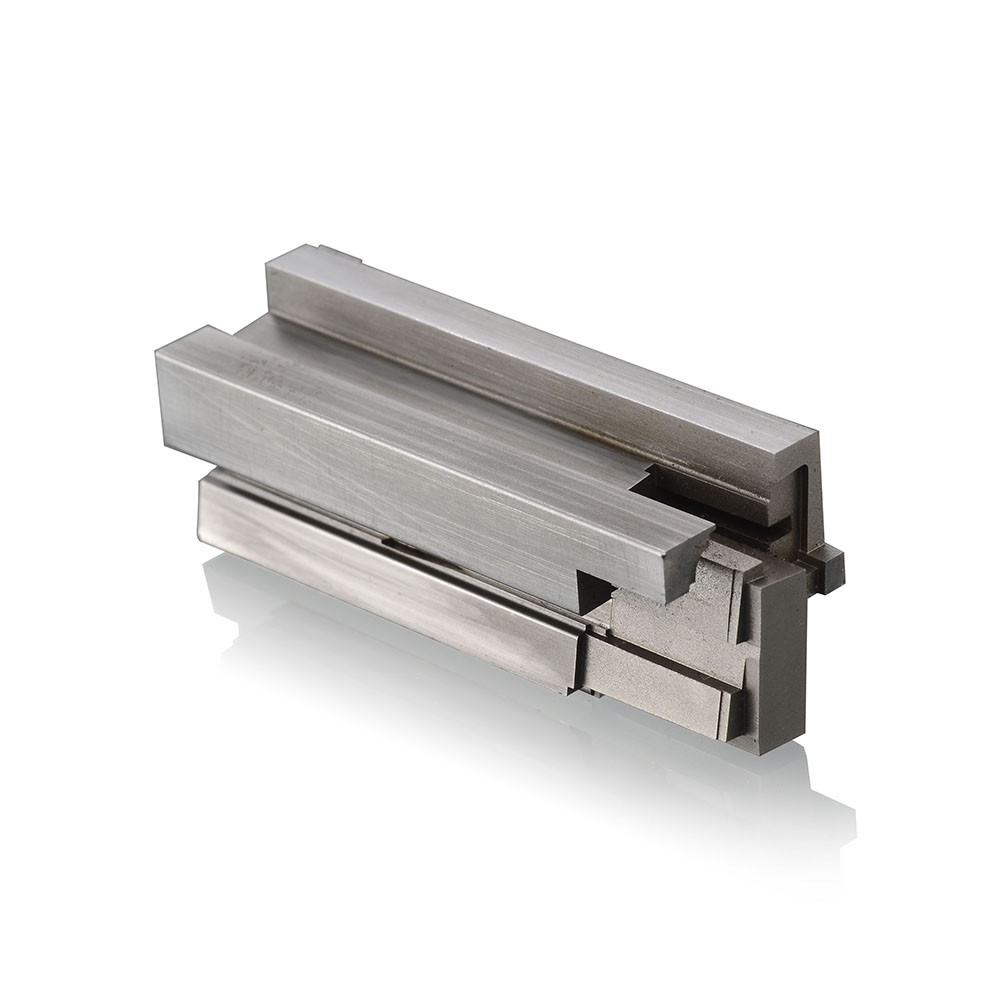

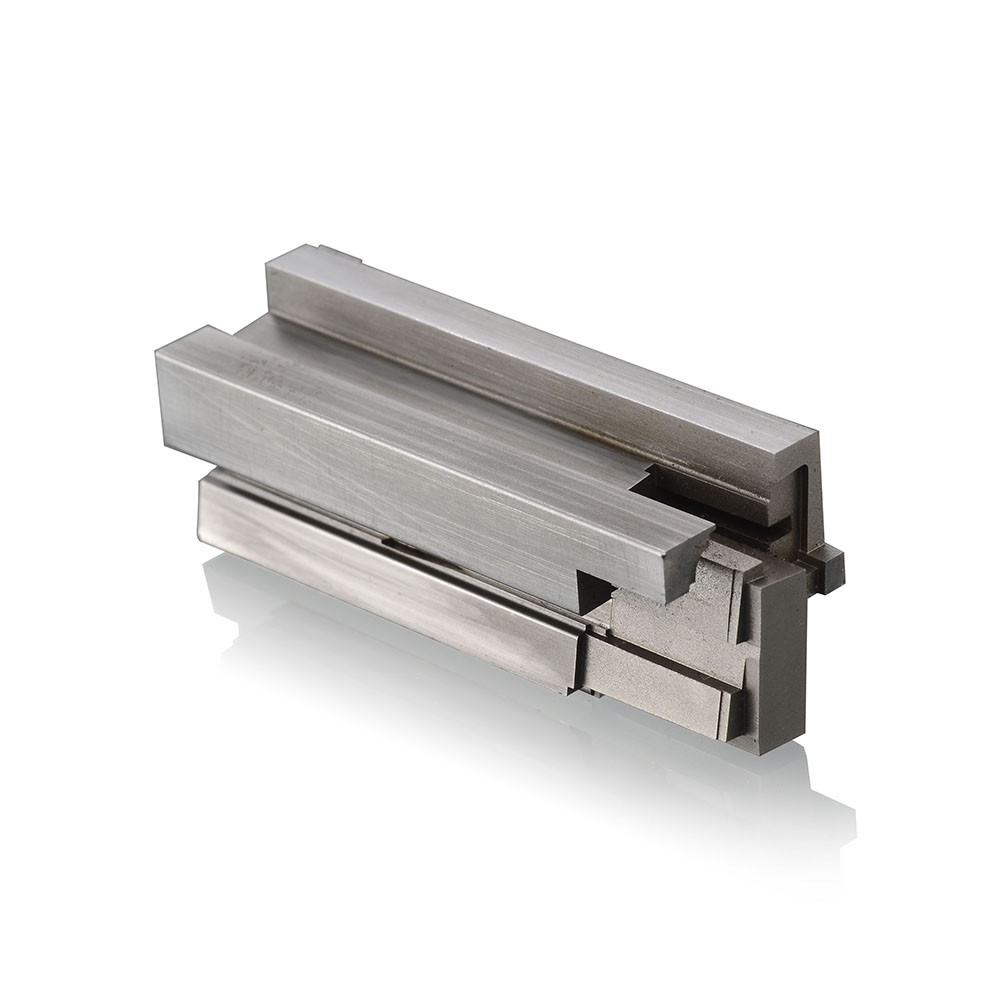

Stainless Steel Square Precision Machined Components of Tolerance 0.005

Product Description of These Parts

The exact part of the mold being uploaded is the part that our factory is best able to process. If you come to our website, you will see more precision mold parts. Apart from square parts, we can also customize the round mold parts for you. We can customize sizes, precision, materials, packaging and shipping, etc.

A. Processing

Three types of injection mold parts shown above, their processing techniques are as follows: flat grinding, discharge machining, wire cutting. Kingrui can also provide processing services, others such as: CNC milling, internal and external grinding, punch molding etc..

B. Matrial

The materials they use are stainless steel materials, SUS440B. With regard to the selection of part materials, our aim is to make the decision entirely in the hands of our clients because we offer custom processing services. Well, in addition to stainless steel, aluminum, zinc, copper, iron, high-speed steel, and so on, we can provide you with.

C) Checking

- For each piece of injection mold parts, we always do the following;

- Each process must be checked;

- Every maker will check the parts he is machining;

- The final comprehensive inspection.

- Sending customer inspection reports.

D. Packing

The first thing to stress is that the packaging can be customized. Although we have regular packing, but for your product safety without any damage, we sometimes customize the packaging according to your product specific situation, or according to your prior requirements for your packing. In a word, our packing is flexible, with product safety as its primary objective.

E. Delivery

Under normal circumstances, we need 5-15 working days after you place an order , the speed of delivery depends on the quantity and complexity of the parts. or according to your claim.

Parts Features

Part Material: 1.3344, SKH51, SKD11, PD613, SKD61, 1.2344, DC53, H13, etc, or according to the customers' requirements.

Part Dimension: According to the your drawings

Injection mold parts color: Black, white, any other colors as per Customers’requirement .

Injection mold parts surface: Polishing, pvd coating, dlc coating , etc.

Mould life: 500,000 shots

OEM: Welcom

Applications: Automobiles, medical, electrical, aviation and so on

File format: Solidworks, Pro/ Engineer, Auto CAD, PDF, JPG ect

Injection mold precision:

- Accuracy of grinding: 0.001 mm

- Accuracy of EDM: 0.002 mm

- Surface roughness: Ra0.4 um

Hardness: HRC58-60, Generally speaking,determined to materials

Our Service And Advantages

1. Fast reply< 24 Hours

2. On- time delivery> 95%

3. Quality control =100%

4. After- sales service> 99% satisfying service

5. Competitive & steady price

6. Advanced equipment and excellent production team

7.High skilled manufacturing process and experienced workers

8. Abroad variety of OEM produvt range

9. Standard export package