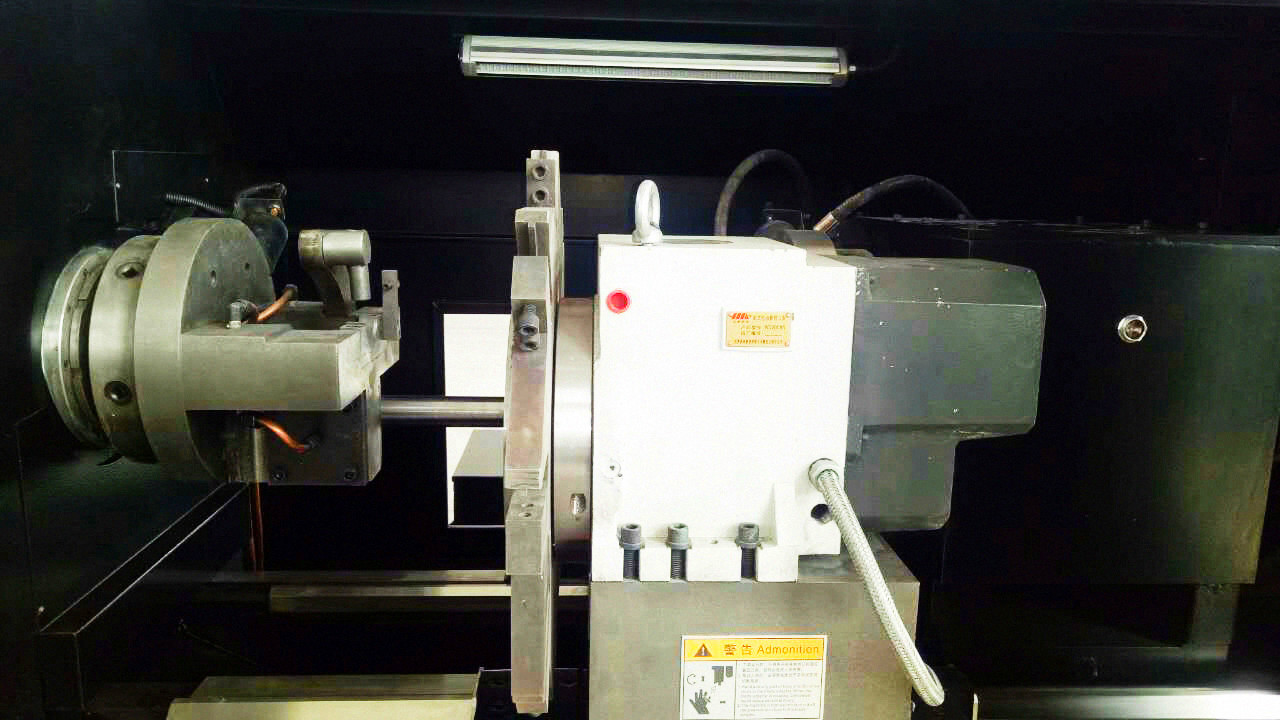

Crankshaft Connecting Rod Neck CNC Lathe

group nameCNC Lathe

-

Min Order1 piece

brand nameDRC

modelSZK8010G

payment methodL/C, T/T

-

update timeThu, 17 Oct 2019 15:50:41 GMT

Packging & Delivery

Min Order1 piece

Briefing

Detailed

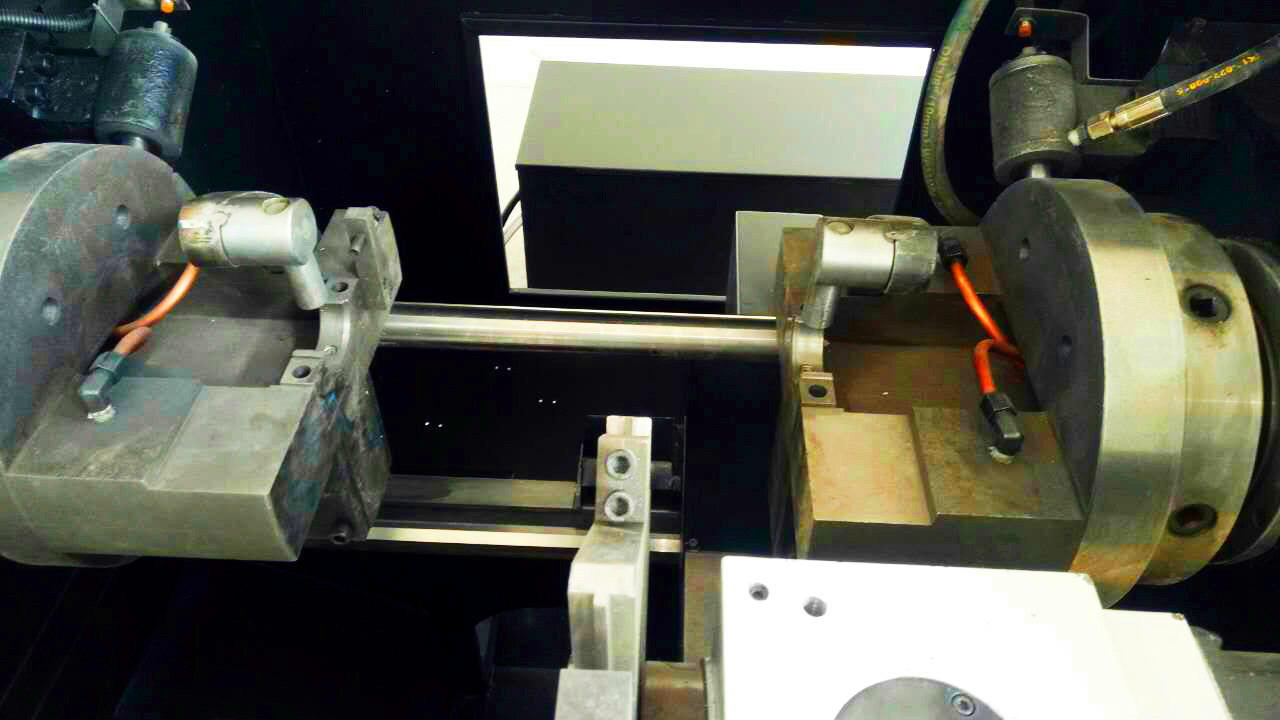

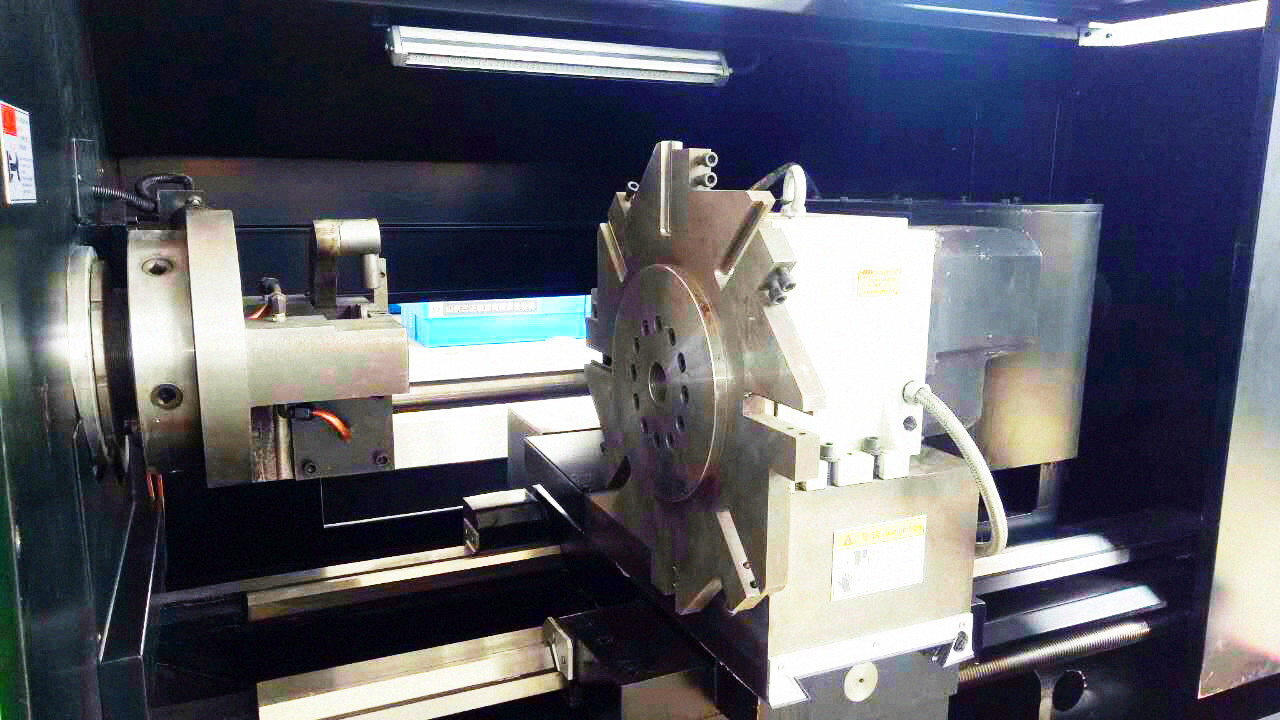

SZK8010G Type Crankshaft Connecting Rod Neck CNC Lathe is a kind of high precision and high efficiency numerical control lathe, developed for machining crankshaft connecting rod neck in automobile industry. It can mainly machine outer ring, shoulder, thrust surface, filleted corner or sinking groove of the crankshaft connecting rod neck. The machine adopts synchronous driving left and right special fixtures, convenient upper and lower crankshaft, ensuring the excellent clamping rigidity of the crankshaft and realizing the processing of the connecting rod neck on a single clamping of crankshaft. The machining accuracy of the crankshaft is improved (so the course grinding procedure of crankshaft can be eliminated), the labor intensity of the operators can be reduced greatly, and work efficiency can be improved multiplied. The right spindle head stock uses the ball splice pair to transfer power, which can ensure the machining precision of the crankshaft with different length. The machine adopts 8-station round cutter head to ensure rigidity of cutting tools in the turning process, and all the procedures can be completed at one time.

Presentation:Customization can be provided according to the type of Crankshaft.

Dalian R&C Machinery Co., Ltd.

E-mail:service..........com

WhatsApp:86-155-6681-6110

Address:No.27Shengming 3rd Road, Dalian Economical & Technological Development Zone, Liaoning, China

You need a product

You May Like

- Nearest port for product export

- Dlian, Ningbo, Shanghai, Tianjing

- Delivery clauses under the trade mode

- FOB, CFR, CIF

- Acceptable payment methods

- T/T, L/C