CNC Automatic Lathe Crankshaft Grinding Machine

group nameSpecialized Machine for End Face

-

Min Order1 piece

brand nameDRC

modelK8010G

payment methodL/C, T/T

-

update timeWed, 26 Dec 2018 10:29:40 GMT

Paramtents

Product Type: CNC Lathe Machine

Main Motor Power: 11 Kw

Max. Swing Diameter: 800

Dimension(L*W*H): Specific Model

Crankshaft Machining Length Range: 250-800 mm

Machine Type: K8010G CNC Automatic Lathe

Precision: High Precision Machine

Spindle Speed: 80-500 rpm

Packging & Delivery

Min Order1 piece

Briefing

Detailed

High Efficiency K8010G CNC Automatic Lathe Crankshaft Grinding Machine

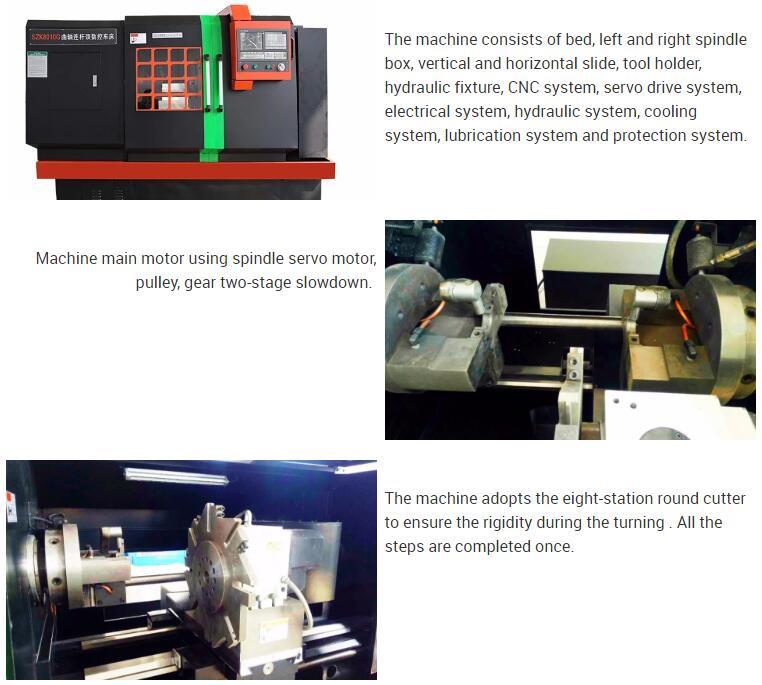

DRC SZK8010G Type Crankshaft Connecting Rod Neck CNC Lathe is a kind of high precision and high efficiency numerical control lathe, developed for machining crankshaft connecting rod neck in automobile industry. It can mainly machine outer ring, shoulder, thrust surface, filleted corner or sinking groove of the crankshaft connecting rod neck. The machine adopts synchronous driving left and right special fixtures, convenient upper and lower crankshaft, ensuring the excellent clamping rigidity of the crankshaft and realizing the processing of the connecting rod neck on a single clamping of crankshaft. . The right spindle head stock uses the ball splice pair to transfer power, which can ensure the machining precision of the crankshaft with different length.

Point Out : Customization can be provided according to the type of Crankshaft.

Ender Users&Delivery

Ender Users&DeliveryCOMPANY INTRODUCTION:

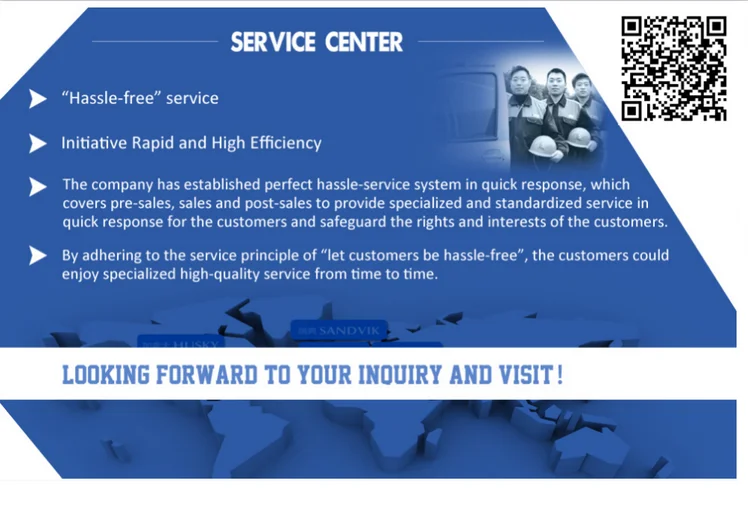

DRC is a group company ,which is professional in products and sales of advanced CNC machine tools . Acting full operation of the six machine tool production company's overseas sales.

DRC is located in Dalian, which is one of the largest seaport cities of China.Our products exported to Russia, Dubai, Hungary, Italy, Argentina, the Philippines, India, Iran, more than 50 countries.

DRC has six factories in China, which covers many kinds of mechanical equipment.

Product Range:

◎CNC Lathe

◎Conventional Lathe,

◎Vertical Lathe

◎Machining Center

◎Boring and Milling Machine

◎Dental Milling Machine

◎Glass Tempering Furnace

◎Special Machine for Pipe Threading ,Valve Milling, End Facing and so on

1. What is your minimum order quantity and warranty?

MOQ is one set, and warranty is one year.

2.What CNC system do you use?

FANUC, SIEMENS, MISTSUBISHI, GSK etc. It depends on your choice.

3.When is the delivery time?

We will delivery it within 90 days after received your payments

4. How to handle the warranty period?

5.Can your company send the technical personnel to our company and direct our workers for free?

When the machine arrive the buyer’s installation site, we timely send mechanical and electrical engineers to install according to the buyer's schedule, the buyer undertakes board and lodging of personnel abroad in the process of installation, and also USD100.00 per day per person. The seller will cooperate with the buyer to deal with visa and installation preparation before going abroad.

You need a product

You May Like

- Nearest port for product export

- Dlian, Ningbo, Shanghai, Tianjing

- Delivery clauses under the trade mode

- FOB, CFR, CIF

- Acceptable payment methods

- T/T, L/C