Horizontal circular table metal surface grinding machines

group nameGrinding Machines

-

Min Order1 set

brand nameDRC

modelM73125

payment methodL/C, T/T

-

update timeThu, 14 Nov 2019 13:20:47 GMT

Paramtents

Max. Grinding Length: 1250mm

Power(W): 15/22kw

Weight: 17000/16000kg

Grinding workpiece diameter: 1250 MM

Table speed: 5-35 r/min

Vertical automatic feed of grinding head: 0.0025--0.03MM

Dimension(L*W*H): 3090/2000/2420mm

Grinding workpiece height: 300 MM

Grinding wheel spindle speed: 1450 r/min

Grinding head vertical feed minimum feed: 0.0025MM

Packging & Delivery

Weight17000.00kg / set

Min Order1 set

Briefing

Detailed

High precision horizontal circular table metal surface grinding machines

Surface Grinding Machines Product Application

M73125 horizontal axis round table surface grinder is a new type of horizontal axis circular table surface grinder developed by DRC Machinery to absorb the advanced grinding machine structure and manufacturing technology at home and abroad. The diameter of the table is ф1250. The overall layout type uses the table to make a rotary motion on the moving carriage. The carriage reciprocates longitudinally on the bed rail. The grinding head assembly moves vertically along the column. The spindle drives the wheel to rotate around. Grinding layout form. The work surface can be angle-adjusted to grind the concave or convex shape to achieve workpiece grinding with internal and external cones. This product is suitable for the surface processing of grinding ring parts, valve sheets, saw blades, milling cutters, gears and other tools manufacturing and mechanical manufacturing precision parts. It can be widely used in tool factories, bearing factories, air compressor factories and general machinery manufacturers. Grinding of precision parts.

Main Features

M73125 surface grinding machine, bed, column, carriage, grinding head and other castings are all made of resin sand technology, good material and high strength. Static pressure guide rail and rail hardened rolling structure are adopted between the main moving parts. The contact rigidity is good, the motion precision is high, the movement is light, the feed is sensitive, the lubrication is simple and reliable, and the service life is long. Spindle bearings, ball screws and electrical components of important parts of machine tools are all well-known manufacturers, and the quality is stable and reliable.

The machine tool can be controlled by the corresponding electric PLC according to the customer's requirements, and the degree of automation is high. In the feed system, there are vertical automatic feeding of the grinding head, rapid lifting, pre-selection of feed parameters, no spark grinding, automatic demagnetization, loss of magnetic protection and other functions, convenient operation and high processing efficiency.

About our company M73125 grinding machine parameters introduction and data:

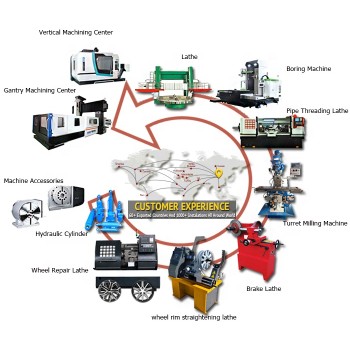

DRC is a group company ,which is professional in products and sales of advanced CNC machine tools . Acting full operation of the six machine tool production company's overseas sales.

DRC is located in Dalian, which is one of the largest seaport cities of China.Our products exported to Russia, Dubai, Hungary, Italy, Argentina, the Philippines, India, Iran, more than 50 countries.

DRC has six factories in China, which covers many kinds of mechanical equipment.

Product Range:

CNC Lathe

Conventional Lathe,

Vertical Lathe

Machining Center

Wheel Repair CNC Lathe

Planer & Slotting Machines

Machine Accessories

Boring and Milling Machine

Laser Cutting Machine

Dental Milling Machine

Glass Tempering Furnace

Special Machine for Pipe Threading ,Valve Milling, End Facing Machine and so on

FAQ

1. What is your minimum order quantity and warranty?

MOQ is one set, and warranty is one year.

2.What CNC system do you use?

FANUC, SIEMENS, MISTSUBISHI, GSK etc. It depends on your choice.

3.When is the delivery time?

We will delivery it within 90 days after received your payments

4. How to handle the warranty period?

During the warranty period, because of product quality problems, the company is responsible for free maintenance, if need to change parts, we be responsible for free replacement.

If the machine problem is not belonging to our machine quality problems, when the buyer needs us send engineers to give repairing service, we charge the appropriate cost.

5.Can your company send the technical personnel to our company and direct our workers for free?

When the machine arrive the buyer's installation site, we timely send mechanical and electrical engineers to install according to the buyer's schedule, the buyer undertakes board and lodging of personnel abroad in the process of installation, and also USD100.00 per day per person. The seller will cooperate with the buyer to deal with visa and installation preparation before going abroad.

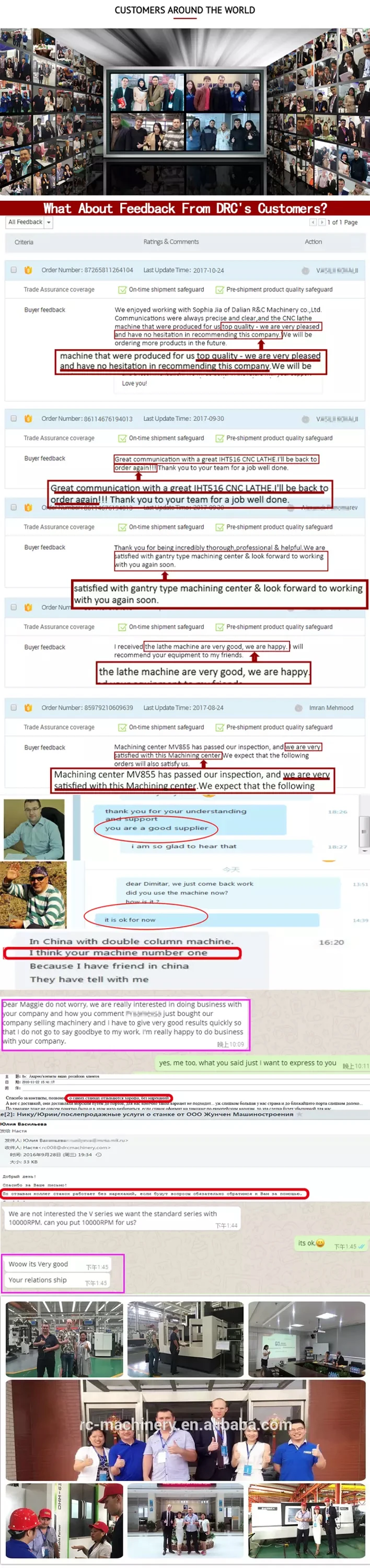

6.What's the trade assurance?

When you look at our alibaba website, you will see the trade security, its purpose is to let every buyer confidence, it can protect your payment, ensure that the suppliers fulfill their commitment to the date of shipment and the quality of the products (as you stated in the purchase order).

If the supplier finds breach of these contractual obligations, alibaba will indemnify you for 100% of your trade guarantee.

Therefore, I believe that through trade guarantees, you will have greater confidence to cooperate with us.

Our company has US $128000' trade assurance limit, it can guarantee your interests.

7.Do your products support trade assurance?

Yes, our products are all supported.

Dalian R&C Machinery Co., Ltd.

E-mail:service..........com

WhatsApp:86-155-6681-6110

Address:No.27Shengming 3rd Road, Dalian Economical & Technological Development Zone, Liaoning, China

You need a product

- Nearest port for product export

- Dlian, Ningbo, Shanghai, Tianjing

- Delivery clauses under the trade mode

- FOB, CFR, CIF

- Acceptable payment methods

- T/T, L/C