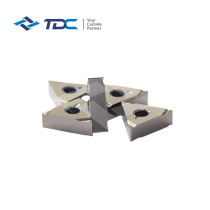

CNC cutting tools,CNC blade,blade,diamond blade

group nameCNC Inserts

-

Min Order20 piece

brand nameTDC

payment method

-

update timeTue, 15 May 2018 14:39:17 GMT

Paramtents

Name CNC cutting tools

Material Tungsten carbide

Type Wear parts

Origin Hunan,China

Density 16.4g/cm

Hardness HRA89-92

Surface Uncoated

Customized Accept

Grade YG8 YN8 YG6X...

Certificate ISO9001

Packging & Delivery

Min Order20 piece

Briefing

Whether the coating: yes

Adapt to the machine: lathe

Type of result: Welding

Detailed

CNC blade model

Type A1: A110, A112, A114, A116 A118 A118A A120 A122 A122A A125 A125A A130 A140 A150 A160 A170

A2 type: A212 A212Z A216 A216Z A220 A220Z

Type A3: A312, A312Z, A315.A315Z.A320.A320Z.A325.A325Z, A330,

A330Z.A340.A340Z

A4 type: A412, A412Z, A416, A416Z.A420, A420Z, A425, A425Z.

B1 type, B22 type, B3 type,

Type C1: C116.C120.C122.C125

Type C3: C303.C304, C305, C306, C308, C310, C312, C314, C316,

C4 type: C420.C425, C430

D1 type: D115, D155Z, D120, D120ZD125.D125Z

D2: D210.D210A, D212, D212A, D214, D214A, D216, D216A.D218.D218A, D218B, D220, D222, D222A, D224, D226, D228, D228A, D230, D232, D232A, D236, D238, D240 , D246

Type E: E108.E109, E210, E211, E213, E214, E215, E216, E217, E320, E325, E330.E515, E522, E525

F-type: F115.F118.

Blade with carbide main grades, performance

Grade | ISO | performance | use | ||

densityg/cm3 | Flexural strength N/m m2 | HRA | |||

YT15 | P10 | 11.1~11.6 | ≥1300 | ≥91 | For carbon steel and alloy steel continuous cutting semi-fine car and fine car. When the intermittent cut fine car, cyclone car wire, continuous surface semi-fine milling and finishing milling, hole expansion and fine expansion. |

YT14 | P20 | 11.2~11.8 | ≥1400 | ≥90.5 | Suitable for continuous machining of uneven surface of carbon steel and alloy steel fine car, intermittent cutting semi-precision car and fine car, continuous face rough milling, drill hole drilling and so on. |

YT5 | P30 | 12.5~13.2 | ≥1560 | ≥89.5 | For carbon steel and alloy steel (including forgings, stampings and castings of the skin) uneven surface cutting rough car, rough planing, semi-fine planing, roughing and so on. |

YS25 | P25 | 12.8~13.2 | ≥1780 | ≥90.5 | Suitable for roughing, milling and planing of carbon steel, cast steel, high-fierce steel, high-strength steel and alloy steel. |

YS30 | P30 | 12.6~12.9 | ≥1850 | ≥90.5 | Suitable for large-size high-speed milling all kinds of steel, especially for the milling of alloy steel, hobbing. |

YG6X | K10 | 14.8~15.1 | ≥1560 | ≥91.0 | Suitable for cast iron, ordinary cast iron finishing and semi-finishing. |

YG6A | K10 | 14.7~15.1 | ≥1510 | ≥91.5 | Suitable for cast iron, non-ferrous metals and their alloys semi-finishing. |

YG6 | K20 | 14.7~15.1 | ≥1670 | ≥89.5 | Suitable for semi-finishing of cast iron, non-ferrous metals and their alloys, non-metallic materials. |

YG8 | K30 | 14.6~14.9 | ≥1840 | ≥89.0 | Suitable for cast iron, non-ferrous metals and their alloys, non-metallic materials, uneven surface and intermittent cutting rough car, rough plane, rough milling, general and deep hole drilling, reaming. |

YD15 | K10 K20 | 14.8~15.1 | ≥1850 | ≥91.0 | Suitable for fine car, semi-fine car titanium alloy, nickel-based superalloy, also suitable for processing all types of cast iron. |

YG8N | K20 K30 | 14.5~14.9 | ≥1840 | ≥90 | Suitable for rough machining of cast iron and non-ferrous metals, also suitable for semi-rough machining of stainless steel roughing. |

YW1 | M10 | 12.7~13.5 | ≥1290 | ≥91.5 | Suitable for heat-resistant steel, high manganese steel, stainless steel, and other processing just just ordinary, cast iron processing. |

YW2 | M20 | 12.5~13.5 | ≥1460 | ≥90.5 | Suitable for heat-resistant steel, high manganese steel, stainless steel and alloy steel and other difficult processing just processing, but also for ordinary steel, cast iron processing. |

YG15 | K40 | 14.5-14.8 | ≥2100 | ≥87.5 | Suitable for oil wells. Coal mining bit. Stretching and stamping die |

YG20 | | | ≥2800 | ≥86.0 | For cold heading. Cold red. Hot forging and other molds |

You need a product

You May Like

- Delivery clauses under the trade mode

- FOB, CFR, CIF, EXW, FAS, CIP, FCA, CPT, DEQ, DDP, DDU, Express Delivery, DAF, DES

- Acceptable payment methods

- T/T, L/C, D/P D/A, PayPal