Polypropylene Melt blown Cartridge with Embossing Surface

group namePP melt blown filter

-

Min Order500 piece

brand nameKTMT

payment methodL/C, Western Union, T/T, Paypal

-

update timeThu, 02 Nov 2017 14:08:28 GMT

Paramtents

Material Polypropylene

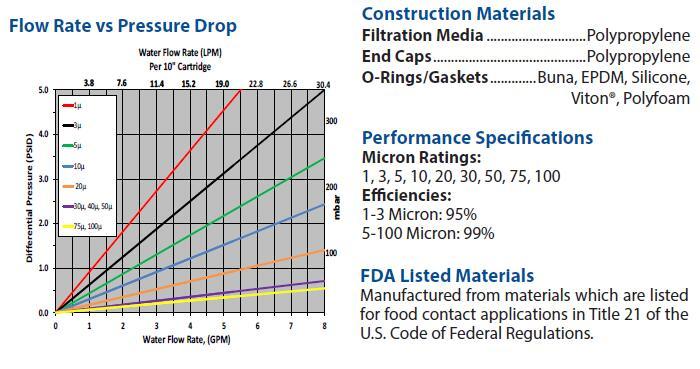

Micron Rate 0.5,1,5,10,25,50,75,100,150,200Micron

Length 10”,20”

Operating Temp. 4-52℃

Max. Operating Pressure 60psi

Max. Flow 4.5GPM (1.5-2kg/Cm2)

End Caps Polypropylene

O-Rings/Gaskets Buna, EPDM, Silicone, Viton®, Polyfoam

Packging & Delivery

Size52cm x 32cm x 32cm

Weight8.00kg / piece

Min Order500 piece

Briefing

Detailed

Polypropylene Melt

blown Cartridge with Embossing Surface

Introduction:

Using

100% Good Grade Polypropylene (Pp) As Material, the filter contains no wetting agents,

solvent, antistatic agents or binders. By special production technology to control

the diameter of pp fibers, the micron rate of the filter is controlled well. Removing

efficiency can reach to 99%. KTMT PP Melt Blown Filter Has 3-Layer. The surface

layer of the filter is designed to be low density to assure the high dirt-Holding

capability, while the inner layer Is higher density to keep the accurate filtration

ability to small particles.

Specification:

|

Material |

Polypropylene |

|

OD: |

2.5” |

|

ID: |

1.1” |

|

Micron Rate |

0.5,1,5,10,25,50,75,100,150,200Micron |

|

Length |

10”,20” |

|

Operating Temp. |

4-52℃ |

|

Max. Operating Pressure |

|

|

Max. Flow |

4.5GPM (1.5-2kg/Cm2) |

|

Filtration Life |

3-5 months/4500G *Depends on water quality and level of

contaminants |

|

End Caps |

Polypropylene |

|

O-Rings/Gaskets |

Buna,

EPDM, Silicone, Viton®, Polyfoam |

|

Efficiency |

1-3 Micron: 95%,5-100

Micron: 99% |

Feature:

• Controlled

fiber diameter and density maximizes removal efficiency and ensures consistent

performance

• Excellent compatibility with a wide range of chemicals

• Easy cartridge incineration and disposal

• All polypropylene construction

• All end configurations available (glued or

thermally-bonded)

• Resists contaminant unloading, even at elevated

differential pressures

• Grooved exterior increases surface area

Application:

l Pre-treatment of drinking water system

l Oil removal industry

l Food and beverages

l Photographic industry

l Pharmacy industry

l Pre-treatment of industrial DI&RO system

l Low viscosity fluids

You need a product

You May Like

- Nearest port for product export

- Tianjin

- Delivery clauses under the trade mode

- FOB, CFR, CIF, EXW

- Acceptable payment methods

- T/T, L/C, PayPal, Westem Union, Cash