Low Temperature High Humidity Air Thawing Equipment for Frozen Pork

- US $100000.0

1 - 2 set

- US $10000.0

3 - 5 set

group nameThawing machine

-

Min Order1 set

brand nameFirst cold chain + freeze food machine

modelThawing machine

payment methodL/C, T/T

-

update timeFri, 05 Dec 2025 14:23:00 GMT

Paramtents

Cooling System Air Cooling

Condition New

Dimension According to Requirements

Refrigeration Valves Brands Valves

Transport Package Sea Worthy Packing

After-Sales Service Assisting Service

Certification ISO, CE, CCC ISO9001

Material Stainless Steel

Energy Efficiency Energy Efficiency and Environmental Protection

Packging & Delivery

Min Order1 set

Briefing

Detailed

1.Extremely low weight loss

2. Low temperature, high humidity defrosting environment

3. Automatically control, easy operation

FEATURES:

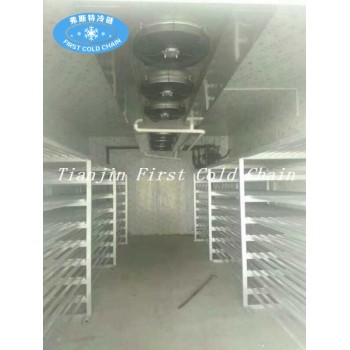

The working principle of defrosting room is utilizing low temperature and high humidity air circulate blow the surface of frozen products and make them defrost evenly and slowly within a small temperature difference. After defrosting, there is a light frost on the surface of defrosting products and the weight loss can be controlled within 1% (Most times, the weight loss can be controlled within 0.5%). After defrosting, the color of products is bright and fresh. The temperature difference between surface and core can be controlled within 2 degree Celsius. The heating method we use is steam heating. The steam source should be provided by customer (Steam pressure: 3kg per square centimeter).

DEFROSTING STAGES:

1. Stage one: inner air temperature from +10 degree Celsius to +4 degree Celsius, 1.5 hours;

2. Stage two: inner air temperature from +4 degree Celsius to +1 degree Celsius, 5.5~9.5 hours;

3. Stage three: inner air temperature from +1 degree Celsius to -3 degree Celsius, 1 hour;

4. Stage four: keep inner air temperature to be -3 degree Celsius for cold storage. (After stage three, the defrosting process is finished. Defrosting room will alarm and it will last 5 minutes. If nobody turns off the machine, it will go to stage four).

MODELS:

DR-1000, DR-2000, DR-3000, DR-5000, DR-10000, DR-20000,DR-30000,

Take DR-1000 for example, the output capacity of DR-1000 is 1000kg every 8~12 hours. That is mean, it can defrost 1000kg products every 8~12 hours according to different frozen products.

Information must be indicated by customer:

1.The size of the existing site ( light * width * height )

2.Products need be defrosted

3.Requirements of the products after defrosted

4.Requirements of heating.

Parameters:

Type | Refrigeration power(kw) | Total power (kw) | Thaw vehicle | Size(m) | Refrigeration unit |

|---|---|---|---|---|---|

1T | 2.9 | 3.4 | 2 | 2.1*3*2 | 1 |

2T | 2.9 | 4.8 | 4 | 3.5*3*3.2 | 1 |

3T | 4.5 | 6.5 | 6 | 3.7.*3.5*3.2 | 1 |

4.5T | 4.8 | 7.5 | 9 | 5*3.7*3.2 | 1 |

6T | 6.5 | 9.5 | 12 | 6.5*3.7*3.2 | 1 |

7.5T | 8 | 12 | 15 | 8*3.7*3.2 | 1 |

9T | 9.8 | 14 | 18 | 9.5*3.7*3.2 | 1 |

10.5T | 11.6 | 16 | 21 | 11*3.7*3.2 | 1 |

12T | 12.9 | 18 | 24 | 12.5*3.7*3.2 | 1 |

15T | 13.5 | 24 | 30 | 8.5*6.5*3.2 | 2 |

20T | 18 | 26.5 | 42 | 11.6*6.5*3.2 | 2 |

25T | 22 | 32 | 48 | 12.5*6.5*3.2 | 2 |

30T | 25 | 37 | 60 | 15.5*6.5*3.2 | 2 |

You need a product

You May Like

- Nearest port for product export

- Tianjin Port, Shanghai Port, Ningbo Port, Qingdao Port

- Delivery clauses under the trade mode

- FOB, CFR, CIF, EXW, CIP, DDP, DAF

- Acceptable payment methods

- T/T, L/C