6000BPH beer filling and capping machine model 32 32 10

- US $42500.00

1 - 1 piece

- US $42500.00

2 - 2 piece

- US $42500.00

3 - 3 piece

- US $42500.00

4 - 4 piece

- US $42500.00

5 - 5 piece

group namebeer filling machine

-

Min Order1 piece

modelOK32-32-10

payment methodL/C, Western Union, T/T

-

update timeSat, 05 May 2018 16:43:22 GMT

Paramtents

Name beer filling and capping machine

Model OK18-18-6

Capacity 3000 Bottles Per Hour

Bottle Type Glass Bottle

Cap Type Crown Cap

Filling Type CO2 Pressure Filling

vacuum Type Two time Vacuum before filling

Machine Function Washing Filling Capping

Machine Size 2400x2000x2200MM

Machine Power Maine motor 3.7KW

Packging & Delivery

Size240cm x 200cm x 220cm

Weight4500.00kg / piece

Min Order1 piece

Briefing

Model 32-32-10

Capacity : 6000BPH

Suitable : Glass bottle Crown cap

CE Certification

Detailed

beer filling and capping machine

Model: 32-32-10

Capacity : 6000BPH

Suitable : Glass bottle Crown cap

Machine instruction : 18 heads washing , 18 heads filling , 6 heads capping .

Machine filling processing : washing bottle --- CO2 into bottle --- Vacuum --- CO2 --- Vacuum --- Filling Beer --- Capping

1.This series of Automatic Glass Bottle Beer Filling Machine can meet the filling-sealin requirements of different sealing manners for crown cap .

2.The Automatic Glass Bottle Beer Filling Machine adopts the advanced international technology .The design is scientific and reasonable ,appearance is beautiful ,operation and maintenance are convenient ,and it is with high degree of automatic. It is the good machine for choosing by the drinking filling factory.

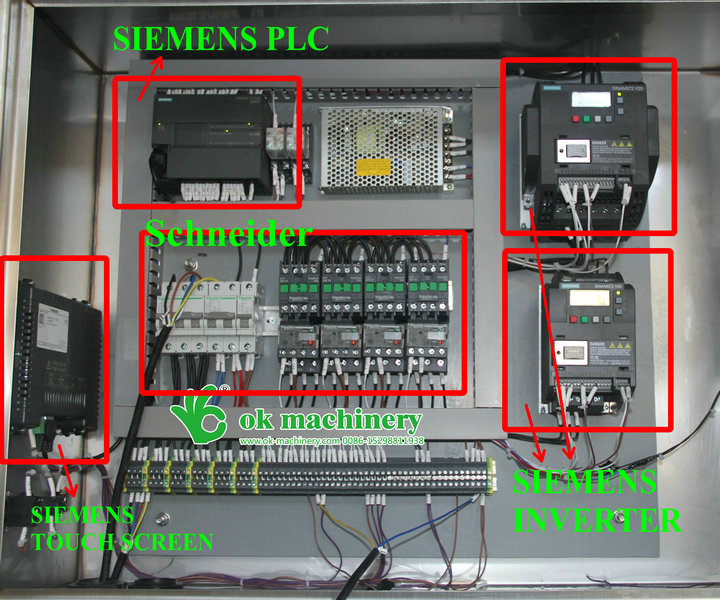

3.This Automatic Glass Bottle Beer Filling Machine is quite easy to be operated and maintained with the adopting of PLC control of frequency conversion Timing. All the parts of Beer Bottling Line contact with liquid are made up of high quality stainless steel, both exterior and interior of the machine are polished for easily cleaning and good hygiene condition. The sealing parts are all imported from foreign countries, which meets the requirement of the hygiene of the food safety.

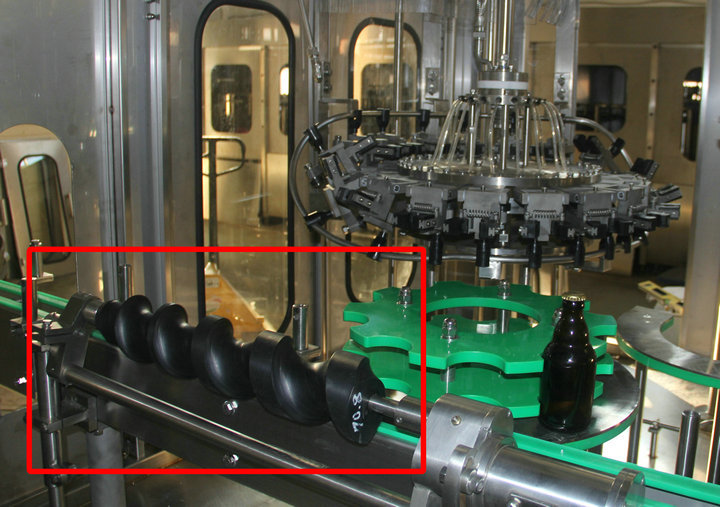

4.Rotatory bottle-rinsing machine has the functions of not opening the valve and rinsing without bottle, which is working from bottle entrance,bottle transportation,bottle clipping,bottle turning around with synchronously rinsing inside of the bottle to water-dropping and exit have the functions of not opening the valve and rinsing without bottles.

5.Adopting the way of filling by holding the necks of the bottle, plus the function of pre-cover of the centralizing cover with high precise centralization,which ensure the right seating of mouth of the bottle and filling valve,with low liquid loss.

6.Adopting crowning the caps with magnetic force,which passes the torque with powerful and constant magnet,and the torque can be adjusted to meet the need of many kind of plastic cap

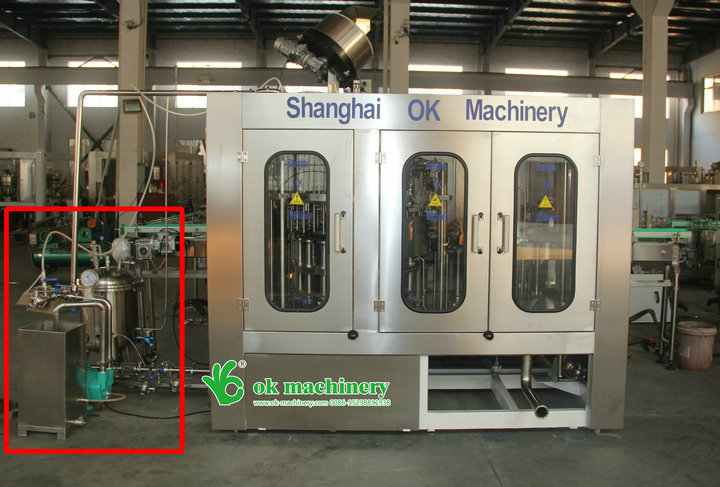

7.The advanced CIP series can clean and sterilize all the containers and insides of all pipes before and after the operation.

8.The Beer Bottling Line adopts the advanced international technology .The design is scientific and reasonable ,appearance is beautiful ,operation and maintenance are convenient ,and it is with high degree of automaticization. It is the good machine for choosing by the drinking filling factory.

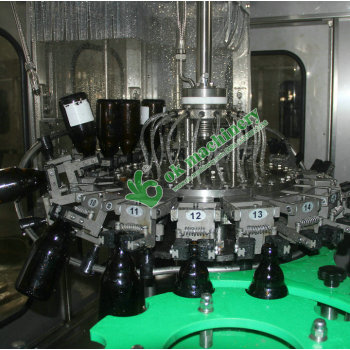

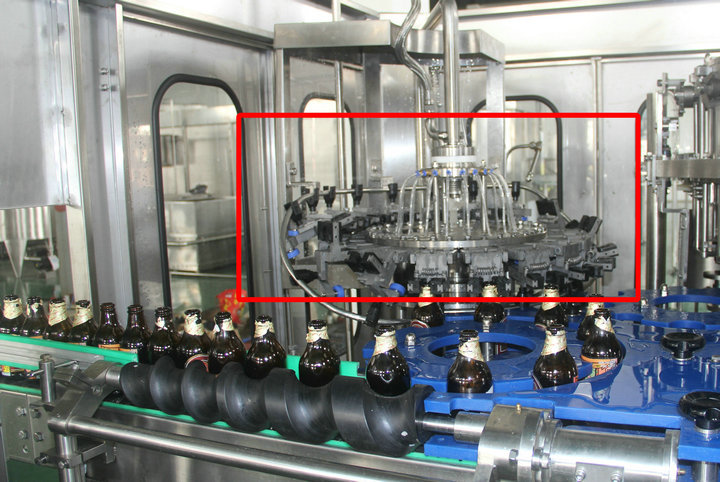

1. self filling beer machine ( washing part picture )

2. self filling beer machine ( filling part picture )

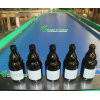

3. self filling beer machine ( capping part picture )

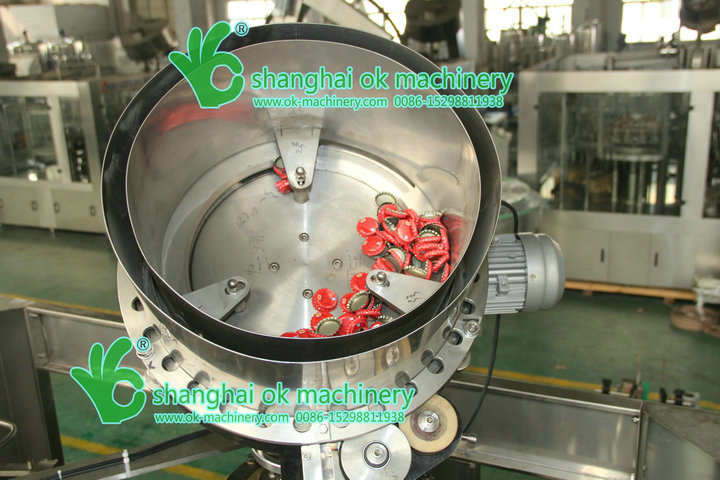

6. caps offer

7. semi automatic beer filling machine( electric part picture )

bottle beer tunnel pasteurizer

Vacuum part and hot pure water injection into bottle mouth

bottle beer label machine

Our Factory

packing and shipping

contact us

You need a product

You May Like

- Nearest port for product export

- Shanghai Port, Ningbo Port, Qingdao Port

- Delivery clauses under the trade mode

- FOB, CIF

- Acceptable payment methods

- T/T, L/C, PayPal, Westem Union, Cash