Our company introduced a new frame, using CNC cutting technology. In 2018, the car was already in advance.

Our company introduced a new frame, using CNC cutting technology. In 2018, the car was already in advance. The

frame is called "Hicoin", the first time processing specific secrecy, but we affirm that, at the beginning of 2018 in

the Chinese factory on the frame for mass production. The product quality monitoring program is operated by our

company and can be adjusted on the basis of the original frame according to your special requirements.

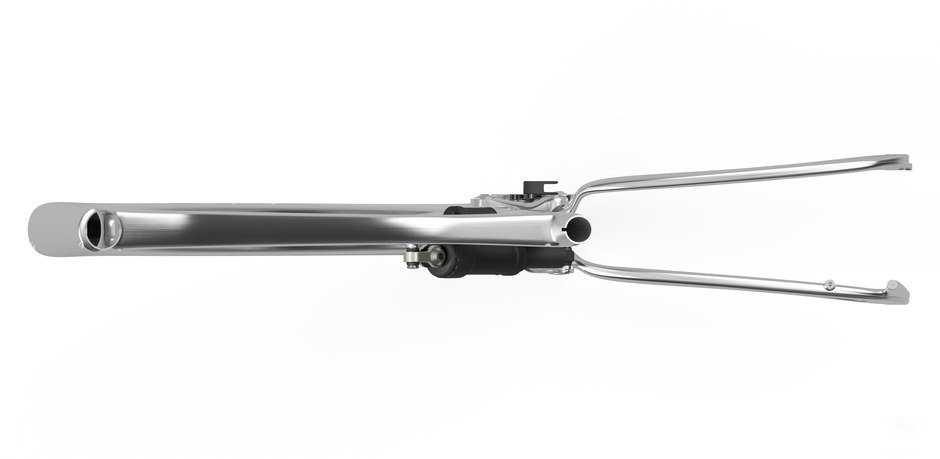

The frame can be fitted with a super frame used in a 29 inch wheel group and can be used for almost any occasion.

This car carries the front fork of the 180mm shock trip and has a 160mm rear wheel stroke

. The frame still uses a long and prone geometry with a straight riser with a better angle to get a better slope. When

we test, we found it was easier to ride the car.

It is the same as our other frame, the frame and the connecting rod material is 7075 T6 billet, with the titanium alloy

axis.

Our products have the advantages of almost every angle, lighter, stronger and faster. We know that all the

manufacturers advertise it, but we can guarantee no falsehood. It should be one of the fastest cars in the world at

the moment.

In the process of processing, we can control the thickness of the tube wall, not the thickness uneven like the

hydroforming. If we compare this process with carbon fiber processing, our technology is not only faster and

cleaner, but also a more humane way of bicycle manufacturing in our view. We are very sure about the intensity of

each position of a single car, unlike carbon fibers, with only approximate estimates and assumptions. Our bike is

very safe to use, and you can even see where the frame is likely to be damaged. If it is a carbon fiber frame, it is

necessary to use ultrasonic testing to determine whether the frame is safe enough.

Most of the single cars need to be painted, because the appearance of the finished product is not attractive

enough. But we keep frame after machining the unique texture, the biggest advantage of doing so is not cause

scratches and wear on the frame. 7075 the surface of the aluminum alloy is very hard, and the surface of the

machined surface can hide scratch and wear marks. The natural oxidation process of the frame forms a beautiful

luster, not as old as a coated single car. There may be a painted version in the future, but what we like most now is

the appearance of the original metallic luster.