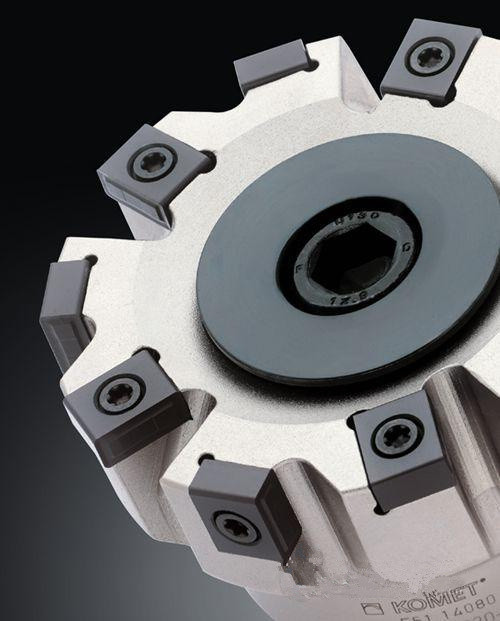

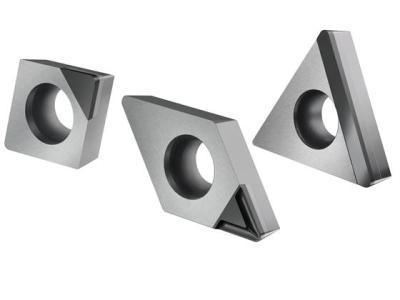

Custom alloy cutters, ceramic cutters, diamond cutters, and CNC tools

group namehardware fitting

-

Min Order1 piece

brand nameHicoin

payment methodL/C, D/A, D/P, MoneyGram, T/T, Paypal

-

update timeWed, 28 Feb 2018 17:14:08 GMT

Paramtents

Place of Origin TianjinChina

Port OR Air port Tianjin,Shanghai,New York,Etc

Molding process Low pressurecasting OR CNC

Types of special casting Metal mold casting

Package Wooden cases, iron cases or according to custom stransportation and customer needs

Specific ations According to customer drawing need

Materials used in manufacturing alloy etc.

Packging & Delivery

Min Order1 piece

Briefing

Detailed

main cutting jobs is the main cutting edge or the main blade knife before and after the

intersection of surfaces, it bears the main cutting jobs is the main cutting edge or the main

blade.

There are many reasons for abnormal wear, cutting tool materials are: toughness or

hardness is too low; geometric structure or the angle of the cutting tool is not reasonable,

the cutting edge is too weak or too large cutting force; cutting parameters selection is not

reasonable, the cutting force is too large or too high cutting temperature; cutting tool due

to sudden heat quenching (such as intermittent cutting and the cooling fluid) too large

thermal stress resulting in crack; improper operation so that the cutting edges are subject

to sudden mechanical or thermal shock, so that chipping and hot cracking etc.

The exfoliation caused by mechanical wear is not only on the front of the knife, but also

on the surface of the knives. The exfoliation area that occurs on the front face is generally

smaller than that on the spalling area on the surface of the knives, as shown in Figure 4.

The heat diffusion also causes the exfoliation of the front and rear surface. The abnormal

wear or breakage of the cutting tool, or the fracture of the blade, usually occurs during the

intermittent cutting process, and the tool breakage will occur when the rigidity of the

machining system is poor. Increasing tool material toughness (increasing cobalt content

in cemented carbide tool material, or increasing TiC and TaC content) can effectively avoid

tool breakage. In addition, increasing the strength of the tool structure and increasing the

rigidity of the machining system will reduce the probability of the tool breakage.

You need a product

You May Like

- Nearest port for product export

- Tian Jin, Shang Hai

- Delivery clauses under the trade mode

- FOB, CFR, CIF, EXW, FAS, CIP

- Acceptable payment methods

- T/T, L/C, D/P D/A, PayPal