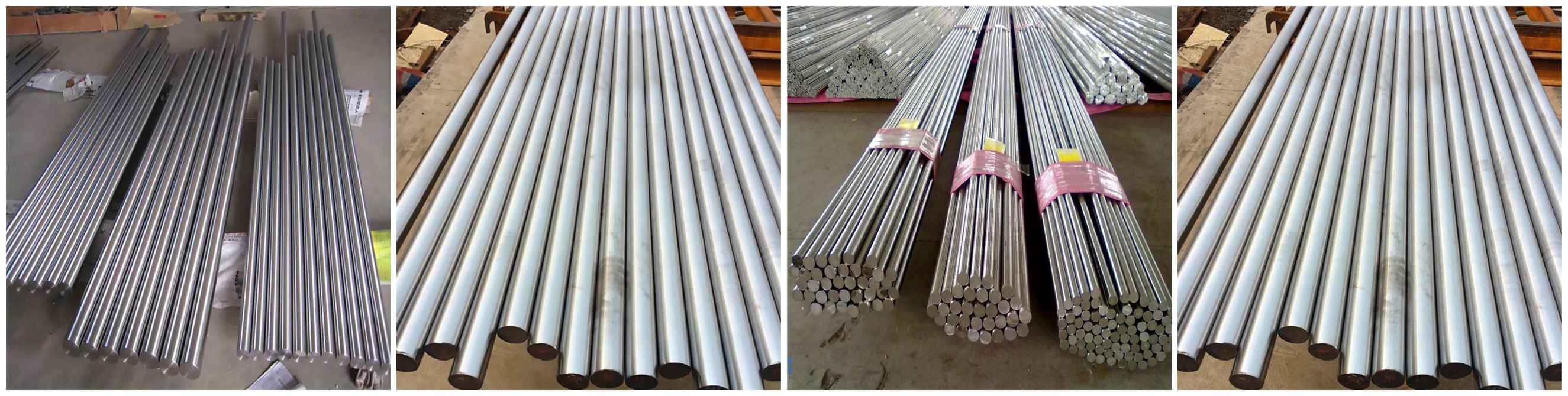

Incoloy 800/800H/800HT N08811 N08810 N08800 1.4876 1.4959 Nickel Alloy Bar

group nameNickel Alloy Bar

-

Min Order1 piece

brand namefushun

modelIncoloy 800/800H/800HT N08811 N08810 N08800 1.4876

payment methodL/C, T/T

-

update timeTue, 23 Jun 2020 10:48:02 GMT

Paramtents

Diameter Range 10-300mm

Length Range 1000-9000mm

Delivery Condition Annealed

Surface Condition Bright

Packging & Delivery

Min Order1 piece

Briefing

Detailed

Introduce

Applications

Plate, Sheet, and Strip:

Pipe and Tubes:

Other Product Forms:

Chemical Composition

Grade | Al | C | Co | Cr | Cu | Fe | Mn | N | Ni | P | S | Si | Ti |

Alloy 800 | 0.3 | 0.015 | 0.01 | 22 | 0.75 | Bal | 0.25 | 0.03 | 34 | 0.2 | 0.02 | 0.5 | 0.5 |

Mechanical Properties

Alloy | Form | Condition | Ultimate Tensile Strength, ksi (MPa) | Yield Strength at 0.2% offset, ksi (MPa) | Elongation in 2" or 4D, percent |

800 | Sheet, Plate | Annealed | 85 (586) | 40 (276) | 43 |

800 | Sheet, Plate Strip, Bar | Annealed | 75 (520)* | 30 (205)* | 30* |

800H | Sheet, Plate | SHT | 80 (552) | 35 (241) | 47 |

800H | Sheet, Plate Strip, Bar | SHT | 65 (450)* | 25 (170)* | 30* |

You need a product

Related Searches

You May Like

6YRS FUSHUN Metals

- Nearest port for product export

- Tianjin, Qingdao, Shanghai, Huangshi

- Delivery clauses under the trade mode

- FOB, CFR, CIF, CIP, CPT, DDP, DDU, DAF

- Acceptable payment methods

- T/T, L/C, D/P D/A