Solar panel raw material Bus Wire for Crystalline Silicon

group nameSolar panel raw material

-

Min Order1 kilogram

brand namesufusolar,saikangguangdian,shanggui

payment methodL/C, T/T

-

update timeThu, 01 Nov 2018 11:12:57 GMT

Paramtents

Brand Nam Shanggui

Model Number solar panel soldering wire

Application solar cell connection

Yield strength ≤70MPa

Lead series Sn60% Pb40%

Soldering tin melting point 180−230°c

Electric Resistivity of Ribbon ≤2.2* 10‾8Ωm

Packging & Delivery

Min Order1 kilogram

Briefing

Detailed

Solar panel raw material Bus Wire for Crystalline Silicon

Coating Component: Sn 62%, Pb 36%, Ag 2%

Base Material: oxygen-free copper ( TU1 or CAD-110 or UNS C11000)

Solder Tin Melting Point: 179-217°c

------------------------------------------------------------------------

Technical Features of PV product

Electrolytic flat copper wire of high purity 99.95%, smooth, brilliant, cleaning. Out of scales and strokes, plated by dipping with tin and lead, or other lead-free chemicals compositions.

About Tabbing Ribbon & Bus bar Ribbon

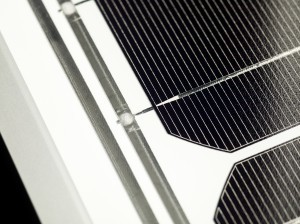

PV ribbon is composed of Copper and coating alloys, and divided into Tabbing Ribbon and Bus bar ribbon.

1. Tabbing Ribbon

Tabbing Ribbon commonly connects the positive and negative sides of the cells in series.

2. Bus bar Ribbon

Bus bar Ribbon concentrates the cell stringing into junction box and channels electrical current.

About Coating Alloy:

The coating type is determined by the customer’s design and demand. It is divided into leaded and dead-free coating. At moment the leaded coating type is widely used, but in the future it will be developed to lead-free coating type.

Main coating alloy types and melting temperatures as follows:

SIZE(mm) | THICKNESS(mm) | COPPER MATERIAL | TOLERANCE | ||

W X T | Base Copper | Coat per side | Width | Thickness | |

2.3x0.13 | 0.1000 | 0.0150 | TU1, T2 | +/-0.05 | +/-0.015 |

2.3x0.15 | 0.1000 | 0.0250 | TU1, T2 | ||

2.5x0.15 | 0.1000 | 0.0250 | TU1, T2 | +/-0.05 | +/-0.015 |

2.5x0.18 | 0.1250 | 0.0275 | TU1, T2 | ||

2.5x2.0 | 0.1500 | 0.0250 | TU1, T2 | ||

3.0x0.10 | 0.0700 | 0.0150 | TU1, T2 | +/-0.05 | +/-0.015 |

3.0x0.15 | 0.1000 | 0.0250 | TU1, T2 | ||

3.0x0.20 | 0.1500 | 0.0250 | TU1, T2 | ||

3.0x0.25 | 0.2000 | 0.0250 | TU1, T2 | ||

4.0x0.15 | 0.1500 | 0.0250 | TU1, T2 | +/-0.05 | +/-0.015 |

4.0x0.20 | 0.1500 | 0.0250 | TU1, T2 | ||

5.0x0.15 | 0.1000 | 0.0250 | TU1, T2 | +/-0.05 | +/-0.015 |

5.0x0.20 | 0.1500 | 0.0250 | TU1, T2 | ||

5.0x0.30 | 0.2500 | 0.0250 | TU1, T2 | ||

5.0x0.35 | 0.3000 | 0.0250 | TU1, T2 | ||

6.0x0.15 | 0.1000 | 0.0250 | TU1, T2 | +/-0.05 | +/-0.015 |

6.0x0.18 | 0.1500 | 0.0150 | TU1, T2 | ||

6.0x0.20 | 0.1500 | 0.0250 | TU1, T2 | ||

6.0x0.23 | 0.1800 | 0.0250 | TU1, T2 | ||

6.0x0.25 | 0.2000 | 0.0250 | TU1, T2 | ||

6.0x0.30 | 0.2500 | 0.0250 | TU1, T2 | ||

6.0x0.35 | 0.3000 | 0.0250 | TU1, T2 | ||

7.0x0.25 | 0.2000 | 0.0250 | TU1, T2 | +/-0.05 | +/-0.015 |

7.0x0.30 | 0.2500 | 0.0250 | TU1, T2 | ||

8.0x0.20 | 0.1500 | 0.0250 | TU1, T2 | +/-0.05 | +/-0.015 |

8.0x0.25 | 0.2000 | 0.0250 | TU1, T2 | ||

8.0x0.30 | 0.2500 | 0.0250 | TU1, T2 | ||

8.0x0.40 | 0.3500 | 0.0250 | TU1, T2 | ||

1,Raw material: we use high-quality materials which ensure the fine conductivity.

2,Molding: We use high precision equipments which ensure the thickness and width of the material.

3,Heat treatment: We use advanced heat treatment equipment with independent innovation to ensure the physical properties of the material.

4,Surface treatment: We use whole sets of the cleaning equipment to ensure the smooth finish of the material surface.

5,Tin-plating: The automatic tin-plating system ensures the stability of the products quality.

6,Packing: our different kinds of packing methods can meet different requirements of customers.

Quality Assurance

1. Technology and Equipment

1) Advanced technology and equipment from German;

2) Advanced measuring technology

3) Stability and reliability of products

2. Management: ISO9001:2000

3. Certificate: SGS, TUV

You need a product

You May Like

- Nearest port for product export

- TIANJIN, SHANGHAI, SHENZHEN

- Delivery clauses under the trade mode

- FOB, CFR, CIF, EXW

- Acceptable payment methods

- T/T, L/C