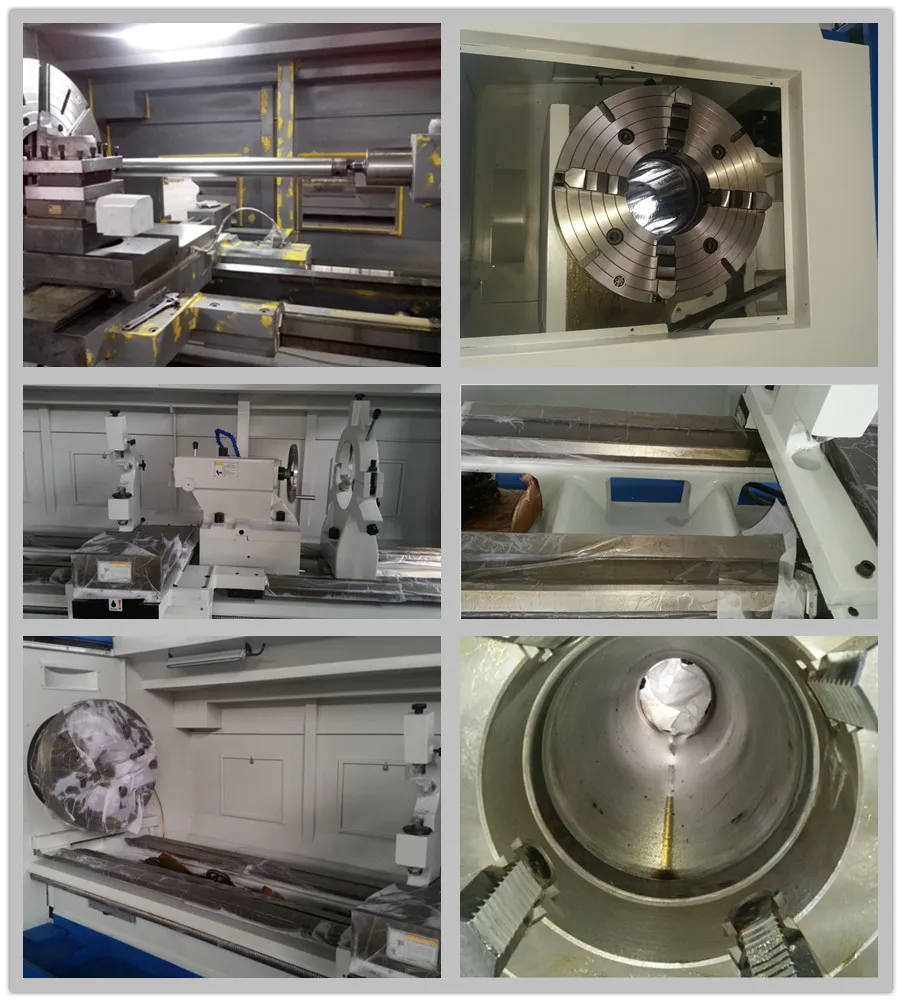

pipe thread lathe CNC

group nameCNC Pipe Threading Lathe

-

Min Order1 piece

brand namesanzheng cnc lathe machine

modelQK1313

payment methodL/C, T/T

-

update timeThu, 26 Mar 2020 12:11:42 GMT

Paramtents

Power(W): 22KW

Guideway width: 490mm

Max.swing over bed: 630mm

Max.swing over carriage: 350mm

Hole through spindle: 130mm

Max.processing Pipe diameter: 126mm

Packging & Delivery

Min Order1 piece

Briefing

Detailed

China Pipe Threads On A Lathe QK series is a special series of machine tools for drilling and metallurgical industry

Application:

The application fields of Pipe Thread Lathe machine are the Processing and repairs of drill pipe, drill collar, joint, kelly bar and sleeve of Oil sector, Metallurgic Industry, Geological Prospecting, Chemical Industry & Hydropower.

Advantage:

We use electric furnace smelting, resin sand molding casting technology,avoid sand holes, stoma casting internal defect effectively, all the accessories are assayed by imported spectrum analyzer, it assures the quality of the casting . The casting had been through second thermal aging treatment with good stability.

The bed of floor type is the whole structure. The rigidity and width of guide way on the bed of lathe is good enough. The guide way is through high-frequency quenching, the slide guide way joint SD compound soft belt. to make more wear-resisting and lower friction factor. The lead screw is the whole structure (not butt). The saddle is wider and thicker than before, the machine is running more stable. And the cutting ability is better.

The 3 boxes of lathe were processed by Taiwan’s CNC boring and milling machine center. The other tools are processed by CNC lathe and machine center to ensure the precision of the box and tools.

First step of the accuracy test of the equipment is testing the repeat accuracy of X and Y axis with Renishaw laser interometer imported from Britain. After that, inspecting and accepting the whole equipment based on the enterprise standards, guarantee the accuracy of the machine tool

2.Superiorities of our products:

1.Compared with other factories, casting material which produced by our company independently is really better than the others. Theproduct adopts the advanced electric furnace melting resin sand molding casting technology, sothe gas permeability is superiorand it can effectively avoid the casting internal voids, porosity.We can absolutely ensure the casting qualityafter the analysis ofUnited States imported equipment precision spectrometer.

2.With the super audio quenching treatment, the hardness ofBody guide rail can reach HRC55 degrees and above. It can keep the hardnesshigh accurate, and prolong the wear resistance and service life. The lathe beds of Other manufacturers are all adopted abutting

joint because of cupola restrictions (1 tons of cupola a pack of hot metal) , but our six electric furnace are 3 tons, So our one to twelve meters lathe bed and guide screw are allfor onewith the better Stiffness and toughness.

3.The lathe bed we produced is all researched and developed by our own engineers. It adopts special structure ,and the natural aging treatment, these all can greatly increased the rigidity and are helpful to widen and thicken the dragging plate, therefore the machine will be more stable and have the stronger cutting ability.

4.The large plate guide rail (X rail) is also adopt the super audio quenching treatment, so it increased hardness and then could guarantee the service life of equipment more efficiently. This is our particular advantage.

5.The reason why using the original mechanical transmission is to make sure that the main motor can also play on the maximum torque when the equipment runs at a low speed . If we just do the frequency conversion, it will getthe lathe stuck and damage the work piece.

6.In order to make sure the accuracy, the equipment will firstly tested by the laser interferometerimported from Britain to testrepeated positioning accuracy of X, Z direction. Then the whole machine will be tested according to the National standard. As long as it passed all the tests, the equipment can be accessed to the market.

E-mail:alice..........com

WhatsApp:86-155-6681-6110

You need a product

You May Like

- Nearest port for product export

- Dalian, Ningbo, Shanghai, Tianjing

- Delivery clauses under the trade mode

- FOB, CFR, CIF

- Acceptable payment methods

- T/T, L/C