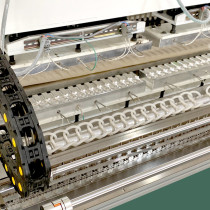

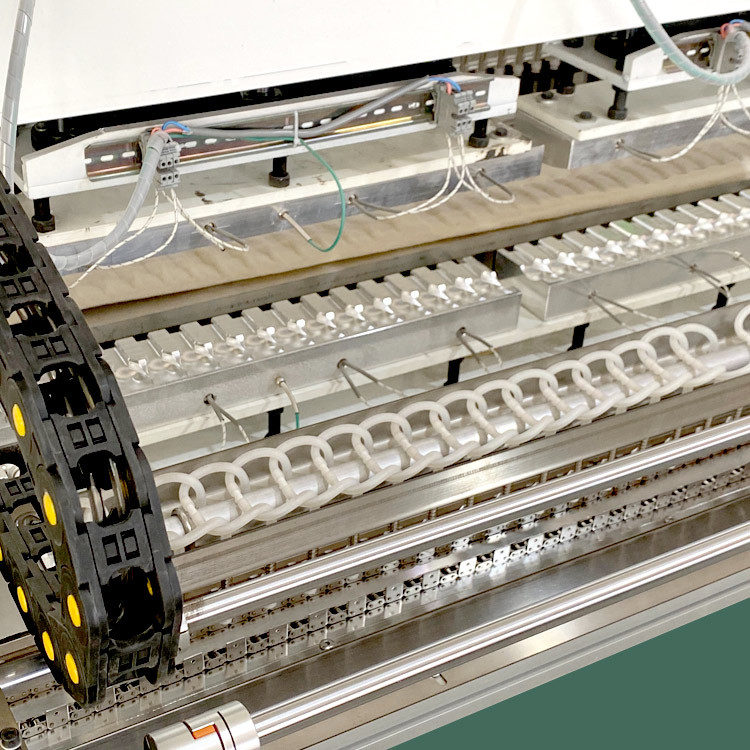

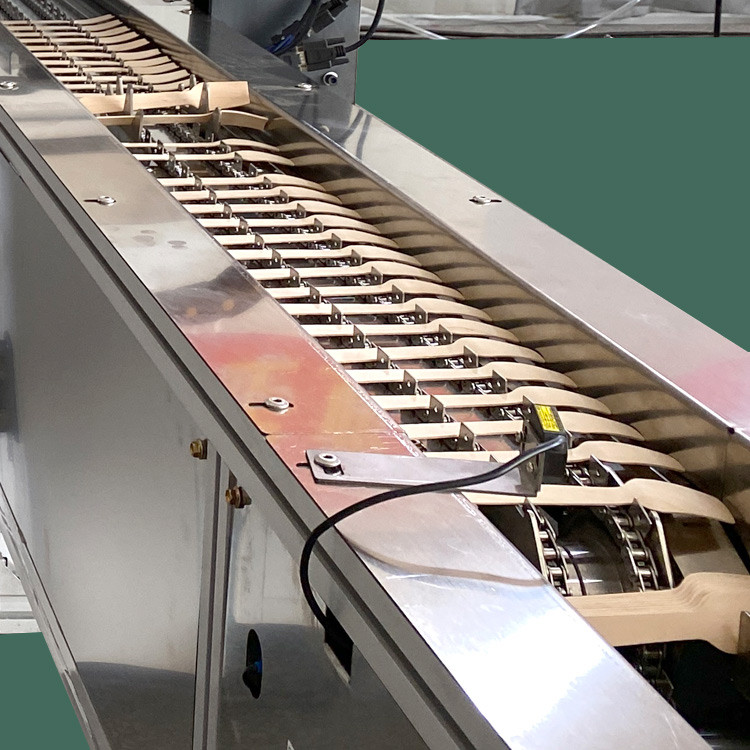

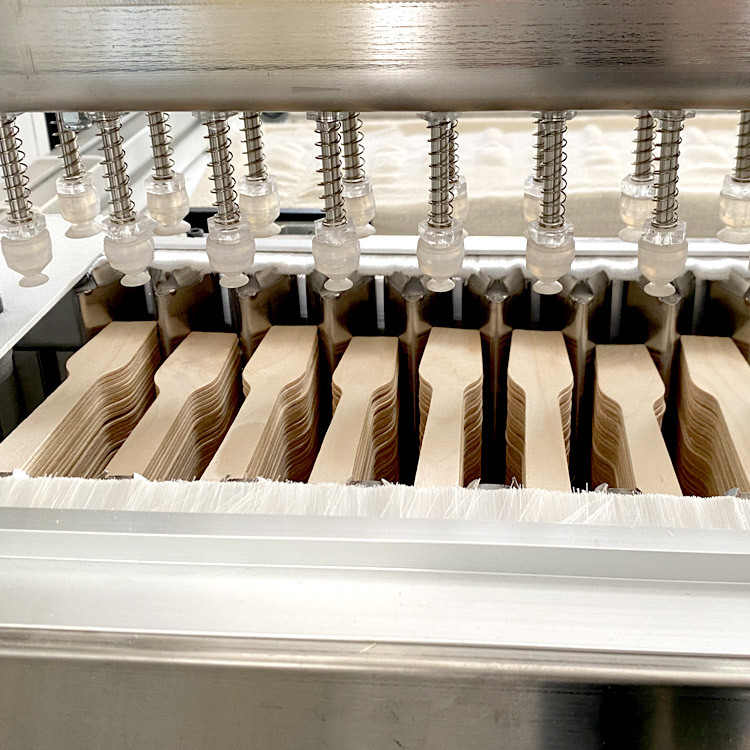

Disposable Wooden Cutlery Making Molding Machine | Spoon and Fork Making Machine | High speed efficiency | Newly upgraded Device

- US $15800.0

1 - 1 piece

group nameWooden Cutlery Making Machine

-

Min Order1 piece

brand nameGreenwood Disposable Wooden Cutlery Manufacturer

modelYXJ-5

payment methodL/C, T/T, Paypal

-

update timeFri, 05 Dec 2025 18:42:00 GMT

Packging & Delivery

Min Order1 piece

Briefing

Detailed

|

Item

|

Data

|

|

Power

|

7.2KW

|

|

Floor space

|

1.5 * 4.4m

|

|

Maximum processing capacity

|

14,000-15,000 PCS / Hour

|

|

Applicable Products

|

Hot pressed cutlery for various sizes

|

You need a product

You May Like

- Nearest port for product export

- Dalian, Shanghai

- Delivery clauses under the trade mode

- FOB, CFR, CIF, EXW, FCA, DDP, Express Delivery

- Acceptable payment methods

- T/T, L/C, MoneyGram, Credit Card, PayPal, Cash