GLK4-600H High Strength Metal Coil Handling Machine For Decoiling Straightening Feeding With Press

group nameGLK4-H 3 in 1 Coil Feeder for Press

-

Min Order1 piece

brand nameHongEr

modelGLK4-1000H

payment methodT/T, L/C, D/P D/A, MoneyGram, Credit Card, PayPal, Westem Union, Cash, Escrow

-

update timeTue, 02 Jul 2019 09:50:46 GMT

Paramtents

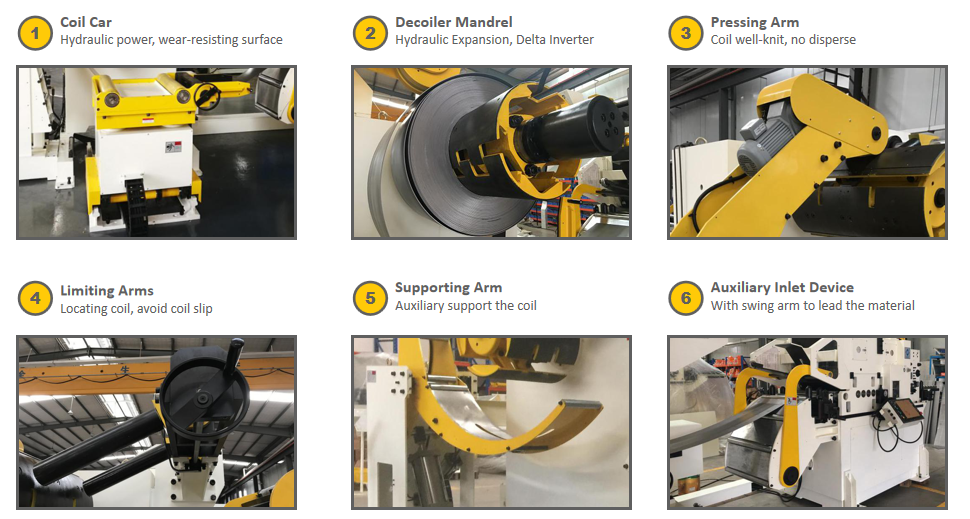

Function servo feeding for high strength coil

Feature thick metal coil handling

Name 3 in 1 decoiler straightener feeder

Compact large tonnage press machine

Usage automotive stamping

attribute uncoiling straightening with auto feeder system

Packging & Delivery

Min Order1 piece

Briefing

Detailed

Model |

GLK4-1000H |

|||

Material | Hot Rolled Steel, Cold Rolled Steel, Galvanized Steel, Painted Steel, Stainless Steel, Copper, Aluminum etc. | |||

Coil width(mm) |

70-1000 |

|||

Coil thickness | 0.6-6.0mm | |||

Coil weight | 7000kg | |||

Coil I.D.(mm) |

480-520 |

|||

Coil O.D.(mm) |

1400 |

|||

Max. speed | 16-24 m/min | |||

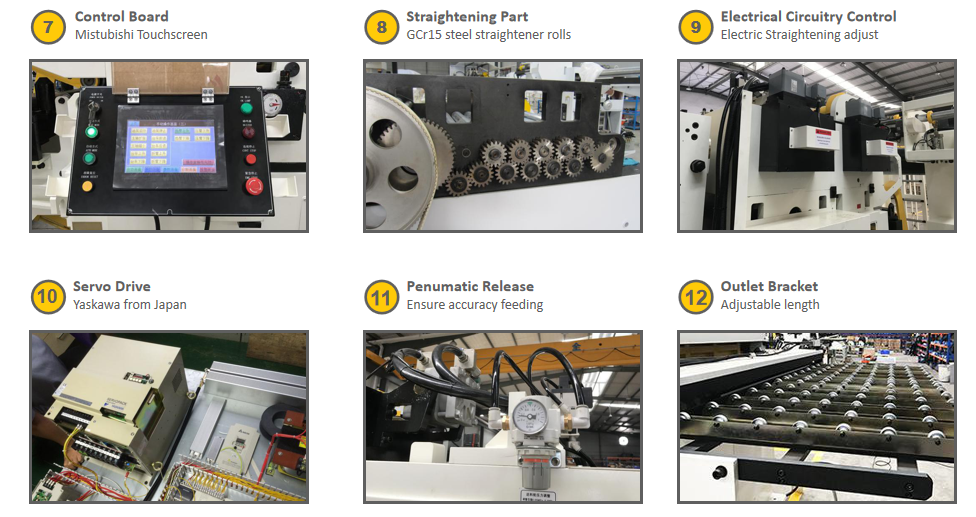

Feeding accuracy | +/- 0.15 mm | |||

Straightener rollers | 4 rollers on top 3 rollers on bottom | |||

Auxiliary Rolls | Φ68mm * 220mm *(1-3) groups | |||

Power | 380V 60HZ | |||

Expansion | Hydraulic | |||

Pressing arm | Pneumatic Type | |||

Servo motor | AC 15KW | |||

Uncoiler motor | AC 5.5KW | |||

You need a product

You May Like

- Nearest port for product export

- Shenzhen Port, Jieyang Port, Shanghai Port, Tianjing Port

- Delivery clauses under the trade mode

- FOB, CFR, CIF, EXW, FAS, CIP, FCA, CPT, DEQ, DDP, DDU, Express Delivery, DAF, DES

- Acceptable payment methods

- T/T, L/C, D/P D/A, MoneyGram, Credit Card, PayPal, Westem Union, Cash, Escrow