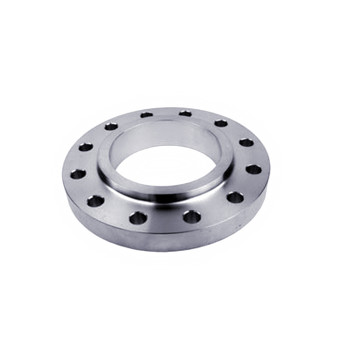

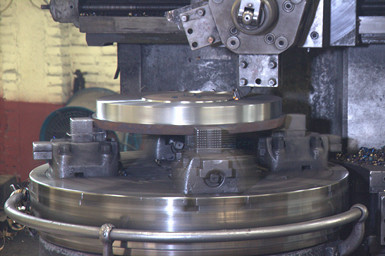

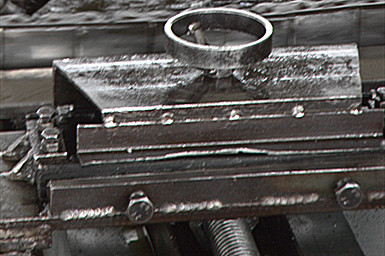

SABS 1123 class 600 1600 pipe flanges slip-on flanges manufacturer and supplier

group nameSlip on flange

-

Min Order1 piece

brand nameJS FITTINGS

modelJS-SO

payment methodL/C, Western Union, MoneyGram, T/T, Crash

-

update timeThu, 26 Nov 2020 16:02:08 GMT

Paramtents

Surface Color yellow, bllack, original color

Application water, oil and gas

Monthly output 500 tons

Brand JS FITTINGS

Type plate flanges, table 15 flanges

Packging & Delivery

Min Order1 piece

Briefing

Detailed

Types of SABS 1123 flanges |

SABS 1123 Weld Neck Flanges SABS 1123 Thraded flanges SABS 1123 forged flanges SABS 1123 Socket flanges SABS 1123 Blind Flanges |

||

Material of SABS 1123 flanges |

Carbon steel: ASTM/ASME A/SA105 A/SA105N & A/SA216-WCB, DIN 1.0402, DIN 1.0460, DIN 1.0619, Die Steel, ASTM A105 / ASME SA105, A105N, ASTM A350 LF2 / ASME SA350, High Yield CS ASTM A694 / A694 (F52 F56 F60 F65 F70 F80) |

||

SABS flanges sealing surface types |

Raised Face (RF), Ring Type Joint (RTJ), Flat Face (FF), Large Male-Female (LMF), Lap-Joint Face (LJF), Small Male-Female (SMF), Small Tongue, Large Tongue & Groove, , Groove |

||

Certificate | ISO 9001 Raw Materials Certificate 100% Radiography Test Report Third Party Inspection Report, etc | ||

Brand |

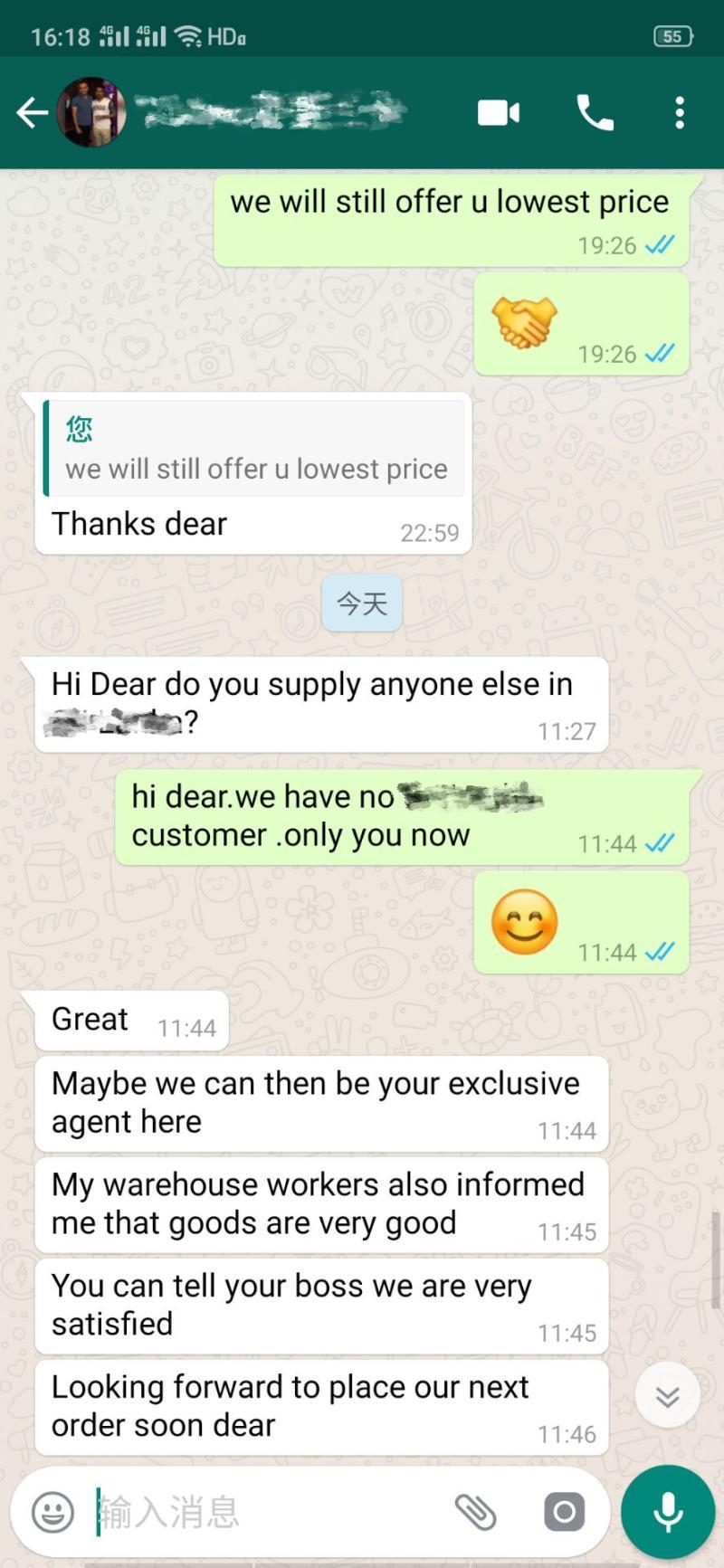

JS FITTINGS |

||

Customized flanges | need drawing and technology data | ||

MOQ | 1-50 pieces for standard flanges, 100 pieces for customized flanges | ||

You need a product

You May Like

- Nearest port for product export

- Tianjin port

- Delivery clauses under the trade mode

- FOB, CFR, CIF, EXW

- Acceptable payment methods

- T/T, L/C, Westem Union