Best Seller Small Boat Yacht Foam Fender with Solid Closed Cell EVA Foam

group nameYacht Foam Fender

-

Min Order1 piece

brand nameJerryborg Marine,safe docking,safe mooring

modelJRBFF

payment methodL/C, D/A, D/P, Western Union, MoneyGram, T/T, Paypal

-

update timeWed, 07 Aug 2019 09:38:50 GMT

Paramtents

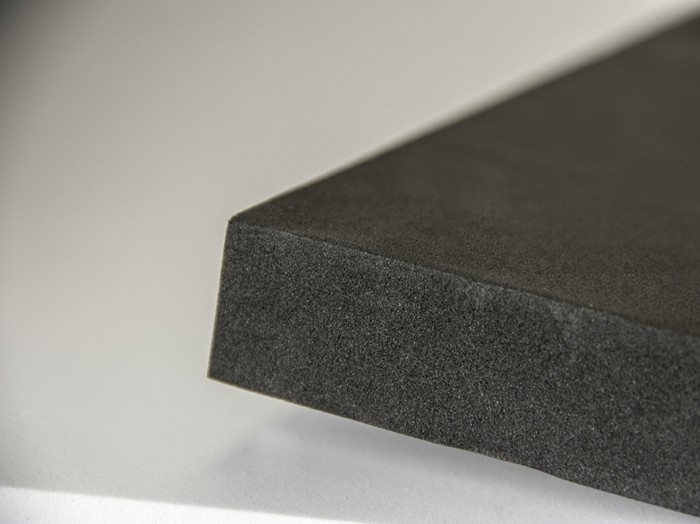

Material closed cell EVA foam

Color white/grey/blue/yellow/red......

Diameter 0.2-4 meters

Length 0.5-6 meters

Coating polyurethane/polyurea

Certificate CCS.ABS.LRS.BV.GL.DNV.NK

Application STS, STD

Brand Jerryborg Foam Fender

Packging & Delivery

Min Order1 piece

Briefing

Detailed

What is Foam Filled Fender ?

Dock Guard Foam Filled Fender is a floating type compressive fender that is highly utility and suitable for a wide range of applications. It is made of an outer Polyurea (SPUA) protective layer, a reinforced rubber nylon cord fabric, as well as an internal space that is filled with 100% closed cell foam as a medium to absorb impact. Foam fenders outer layer has an extremely low frictional resistance and is highly resistant to wear due to its proven strength. Impact force is efficiently absorbed by the close cell foam fender, reducing the resultant force acted upon the wharf/vessel at the point of contact.

Dock Guard Foam Fender can be used for tugs, workboats, pilot boats and is suitable for open sea terminals, gravity ports, especially for large tidal wave docks. Foam fender is also a viable option for Ship-to-Ship (STS) operations.

Advantage of Foam Fender

1. Proportional increase of energy and reaction

2. Extremely robust and

3. No performance loss and unsinkable even if damaged

4. Smaller skin damages can easily be repaired on site

5. Low hull pressure and non-marking Polyurethane/polyurea(SPUA) skin

6. Good angular performance

Structure of Foam Fender

1. 100% closed cell EVA foam

Each cell of EVA foam is separated, so water cannot migrate into the foam, which ensures a high amount of buoyancy, even in case of damage to the outer polyurea (SPUA) coating. Even after many years of active service, the foam core can be returned to the factory, re-skinned and made ready for a new lease of life. A wide range of foam densities are available, from 20Kg/m³ to 200kg/m³, to offer a high dissipation of Energy and a low Reaction Force.

2. Polyurea (SPUA) coating skin

Polyurea is a type of elastomer coating which is sprayed onto the EVA foam core, thereby improving performance of foam fender and giving the fender increased resistance against abrasion during operations. Thickness of Polyurea coating is customized as per customer demand, usually from 3mm to 100mm. Jerryborg’s wear and tear resistant Polyurea coating let our foam fender performs well in even the harshest environments.

You need a product

You May Like

- Nearest port for product export

- Qingdao Port, Shanghai Port

- Delivery clauses under the trade mode

- FOB, CFR, CIF, EXW, DDP, DDU, Express Delivery

- Acceptable payment methods

- T/T, L/C, D/P D/A, MoneyGram, Credit Card, PayPal, Westem Union, Cash