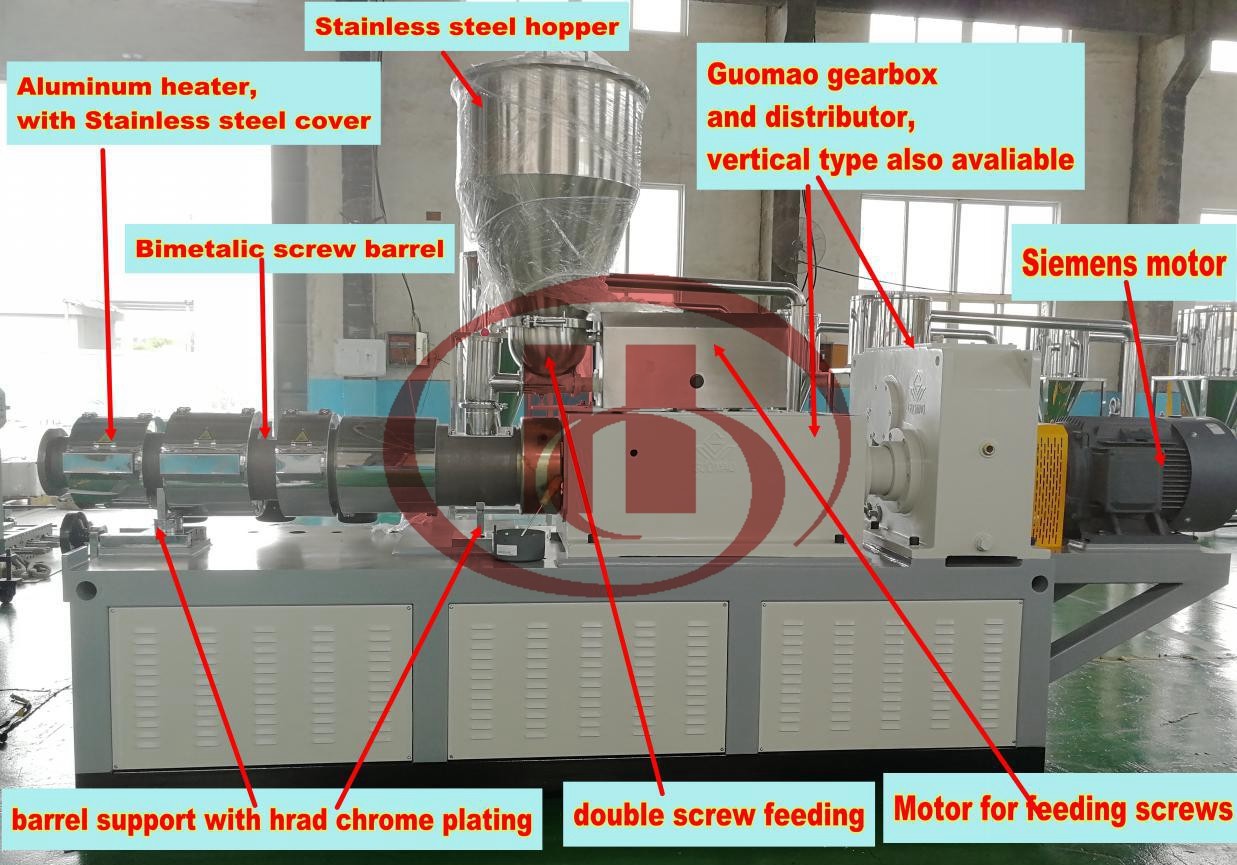

SJMS65/132 Wood Plastic Composite WPC extruder machine

group namePP PE WPC Profile Machine

-

Min Order1 set

brand nameHEGU

modelSJMS65/132

payment methodT/T, L/C, Cash

-

update timeThu, 20 Aug 2020 09:02:46 GMT

Paramtents

machine SJMS65/132 WPC extruder machine

Packging & Delivery

Weight25000.00kg / set

Min Order1 set

Briefing

Detailed

|

|||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Material:38CrMoALA

Bimetallic Material: Tungsten Carbide alloy

Hardness After Hardening&Tempering:HB280-320

Nitrided Hardness:HRC55~58

Nitrided Case Depth:0.45mm-0.7mm

Nitrided Brittleness:Less than Grade 2

Surface Roughness:Ra0.4um

Screw Straightness:0.015mm

Bimetallic Hardness:HRC65

Bimetallic Depth: 2.5 mm

You need a product

You May Like

- Nearest port for product export

- Qingdao Port, China, Any port, China

- Delivery clauses under the trade mode

- FOB, CFR, CIF, EXW

- Acceptable payment methods

- T/T, L/C, Cash