315-630mm large diameter Plastic HDPE Pipe Extrusion Machine for making Water and Gas Pipe

group namePE PPR Pipe Machine

-

Min Order1 set

brand nameHEGU

model75-250mm

payment methodT/T, L/C, Cash

-

update timeWed, 02 Sep 2020 16:07:29 GMT

Packging & Delivery

Min Order1 set

Briefing

Detailed

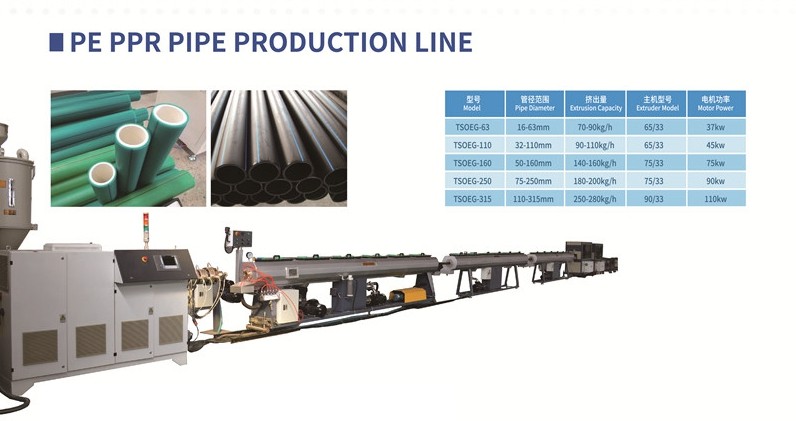

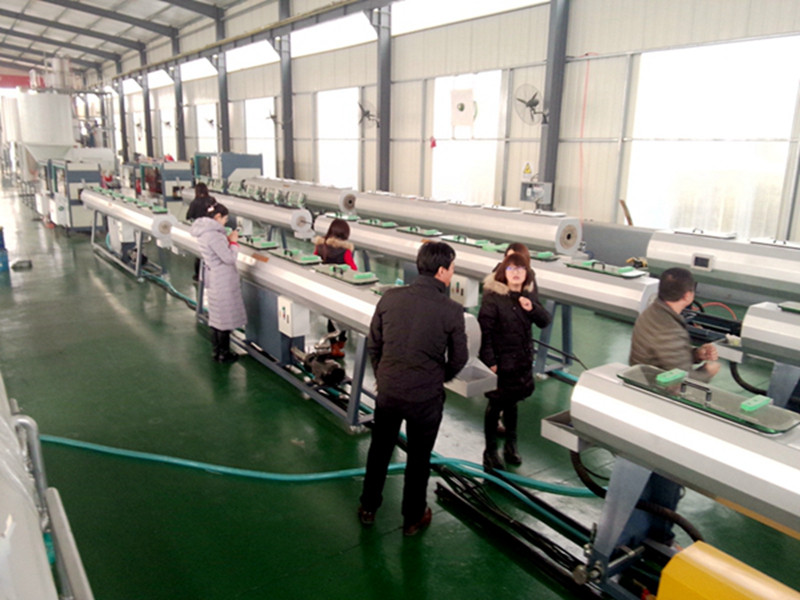

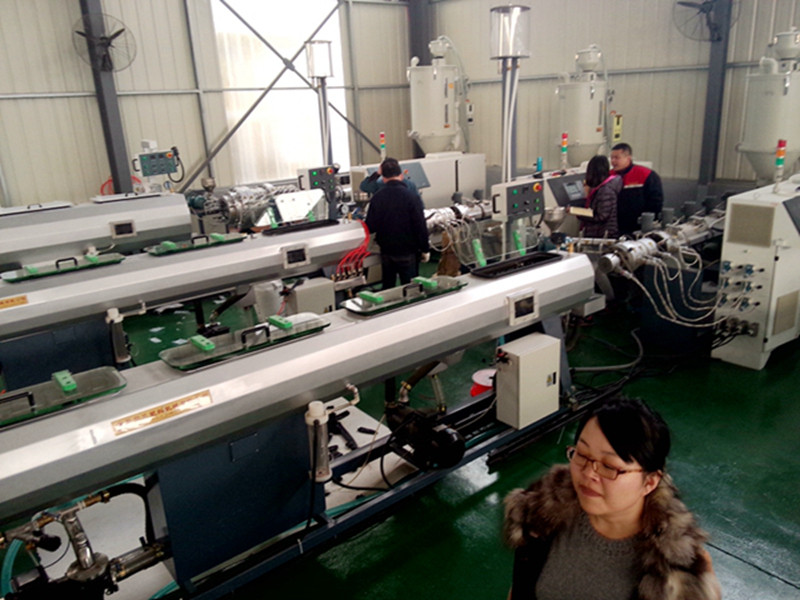

High Speed HDPE Water Supplying and Gas Supplying Pipe Extrusion Line

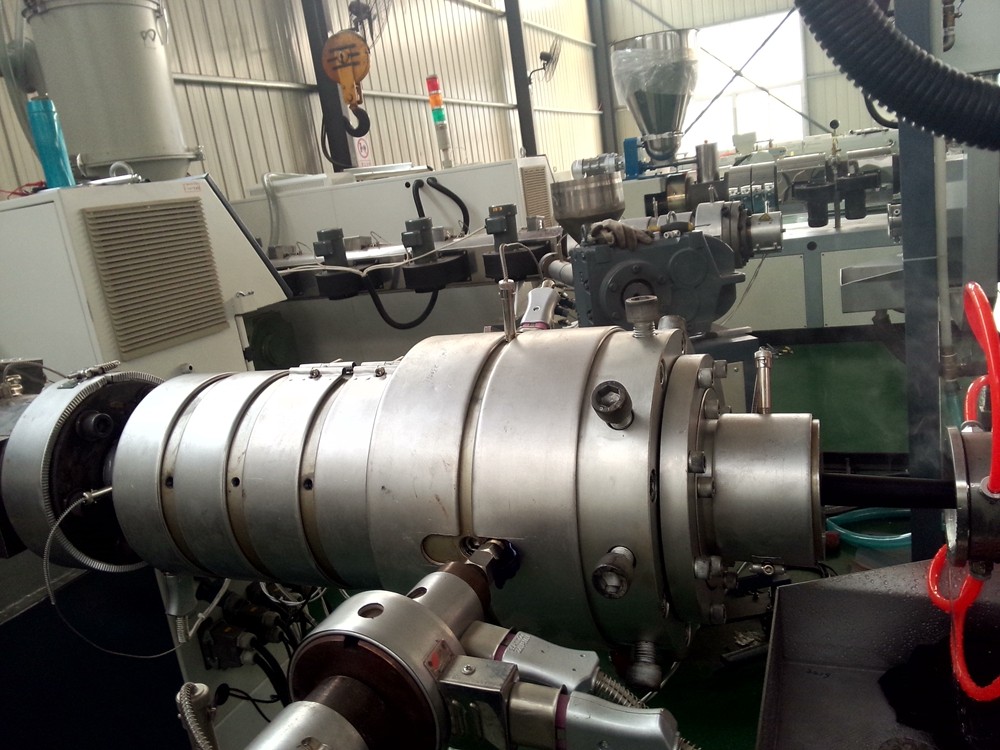

This production line adopts the most advanced technology of Europe,It is a new research achievement of ener- gy-saving production line,which is suitable for high speed extrusion of HDPE,PP and other polyolefin pipe.compared with corn- mon production line,the energy-saving effect reach on 35%,and the product efficiency increase more than 1 times, thus it is not only saving the cost of site and manpower, but also improving efficiency. This production line has nice appearance,higher auto- matical degree, production reliable and stable.

Our company using the development HDPE,PP pipes extrusion technology develops this kind of extrusion line. This line features compact structure, highly automation and stable performance.

This line is widely used in producing HDPE water, gas supply pipe, double-anti pipe for mine industries.

|

for different size of PE pipe making, the quantity and capacity of water and vacuum tank may also different.

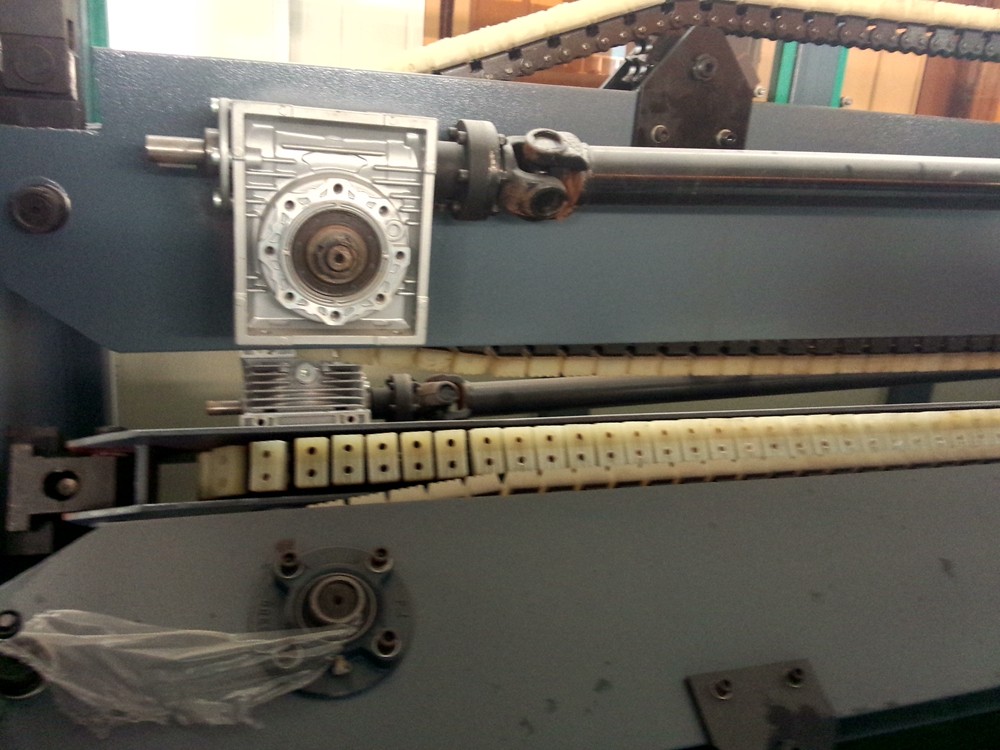

according to the PE pipe size, we shall equip double caterpillar haul off, three caterpillar haul off, four caterpillar haul off, six caterpillar haul off.

the cutter is equipped with PLC touch screen system,

the user can set the cutting length and it shall cut automatically.

the stacking device is 6 meter length, it shall stack the PE pipes together automatically.

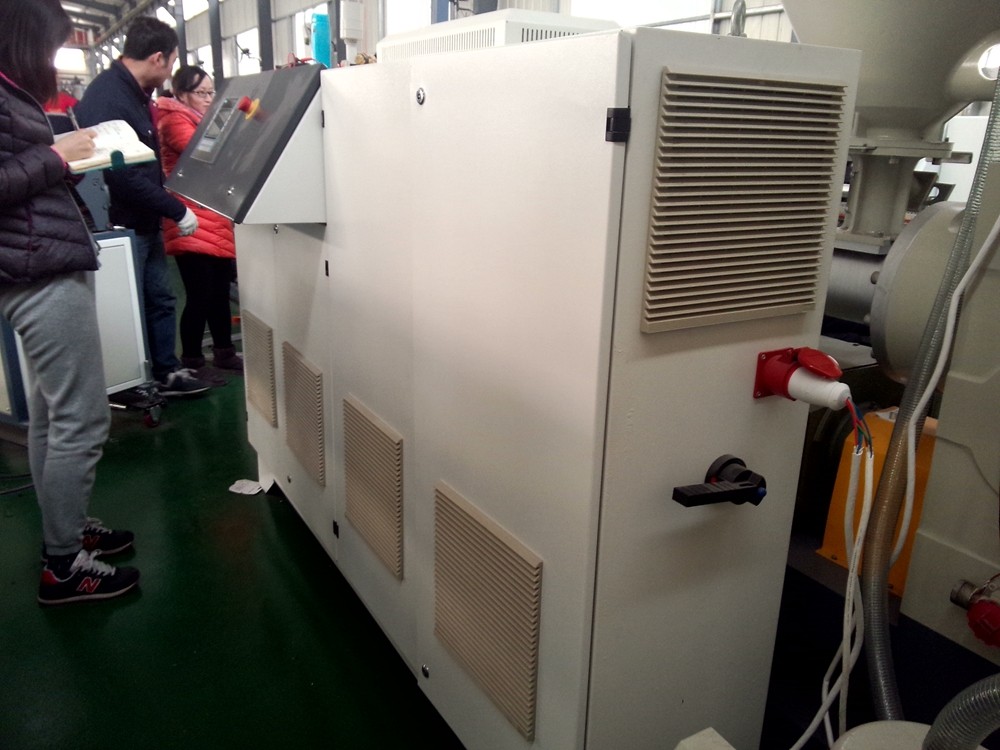

| 1). ABB inverter 2). Siemens contactor 3). Omron temperature controller 4). Siemens motor 5). heat ventilation of cabinet is designed with blowing fans:6 sets 6). Siemens PLC control system is optional |

You need a product

You May Like

- Nearest port for product export

- Qingdao Port, China, Any port, China

- Delivery clauses under the trade mode

- FOB, CFR, CIF, EXW

- Acceptable payment methods

- T/T, L/C, Cash