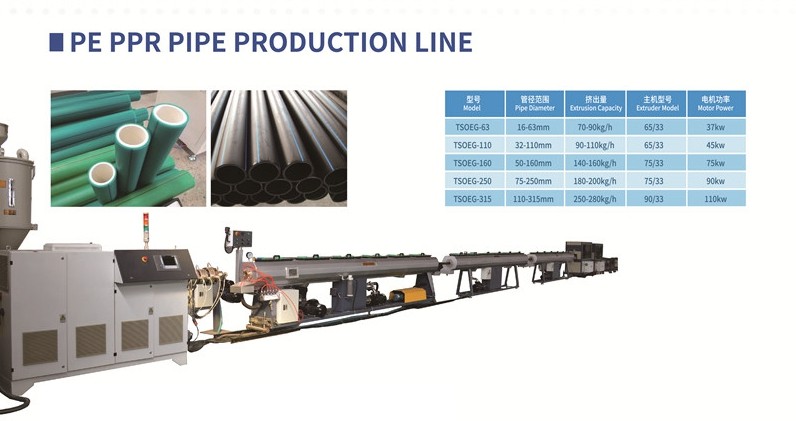

75-250mm Water Supplying HDPE Tube production machine PE Plastic Pipe Making Machine Manufacturer

- US $80000.00

1 - 2 set

- US $78000.00

3 - 5 set

- US $75000.00

6 - 10 set

group namePE PPR Pipe Machine

-

Min Order1 set

brand nameHEGU

model20-110mm

payment methodL/C, T/T

-

update timeMon, 29 Mar 2021 09:49:43 GMT

Packging & Delivery

Min Order1 set

Briefing

Detailed

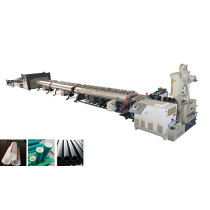

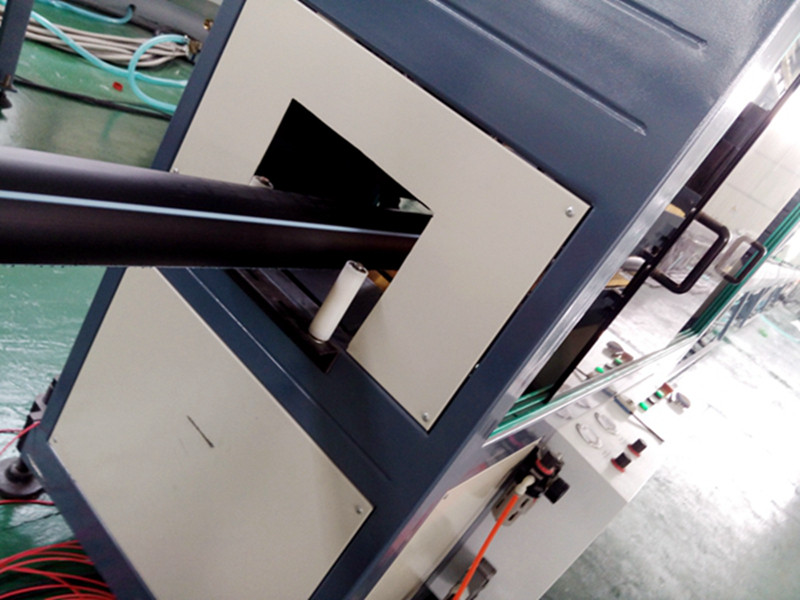

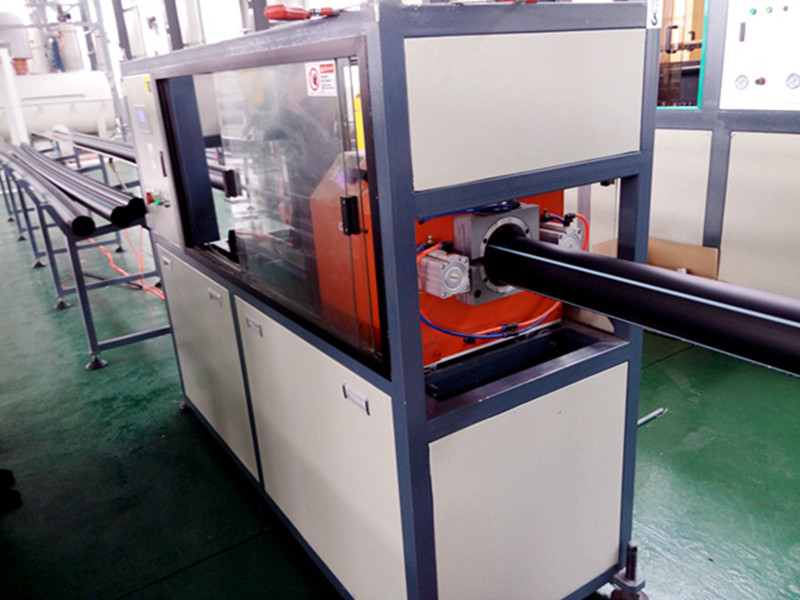

pe pipe line water pipe making machine

|

for different size of PE pipe making, the quantity and capacity of water and vacuum tank may also different.

according to the PE pipe size, we shall equip double caterpillar haul off, three caterpillar haul off, four caterpillar haul off, six caterpillar haul off.

the cutter is equipped with PLC touch screen system,

the user can set the cutting length and it shall cut automatically.

the stacking device is 6 meter length, it shall stack the PE pipes together automatically.

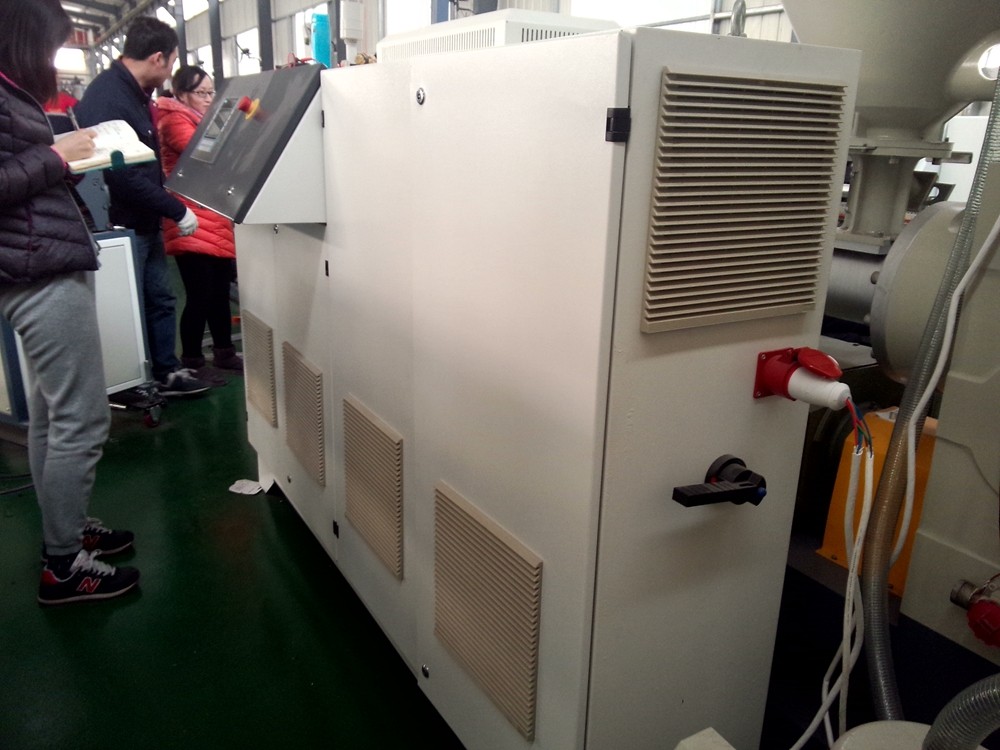

| 1). ABB inverter 2). Siemens contactor 3). Omron temperature controller 4). Siemens motor 5). heat ventilation of cabinet is designed with blowing fans:6 sets 6). Siemens PLC control system is optional |

You need a product

You May Like

- Nearest port for product export

- Qingdao Port, China, Any port, China

- Delivery clauses under the trade mode

- FOB, CFR, CIF, EXW

- Acceptable payment methods

- T/T, L/C, Cash