48 pairs, Aluminum material, inner hollow with water cooling channel, with vacuum cooling

110-300mm HDPE Plastic DWC Double Wall Corrugated Drain Pipe Manufacturing Machine

group nameDouble Wall Corrugated Pipe Machine

-

Min Order1 set

brand nameHEGU

model110-300mm

payment methodL/C, T/T

-

update timeMon, 07 Sep 2020 15:13:52 GMT

Packging & Delivery

Min Order1 set

Briefing

Detailed

Technical details for the double wall DWC corrugated pipe machine:

40-110mm DWC pipe machine

110-300mm DWC pipe machine

Equipment list for the 110-300mm double wall DWC corrugated pipe machine:

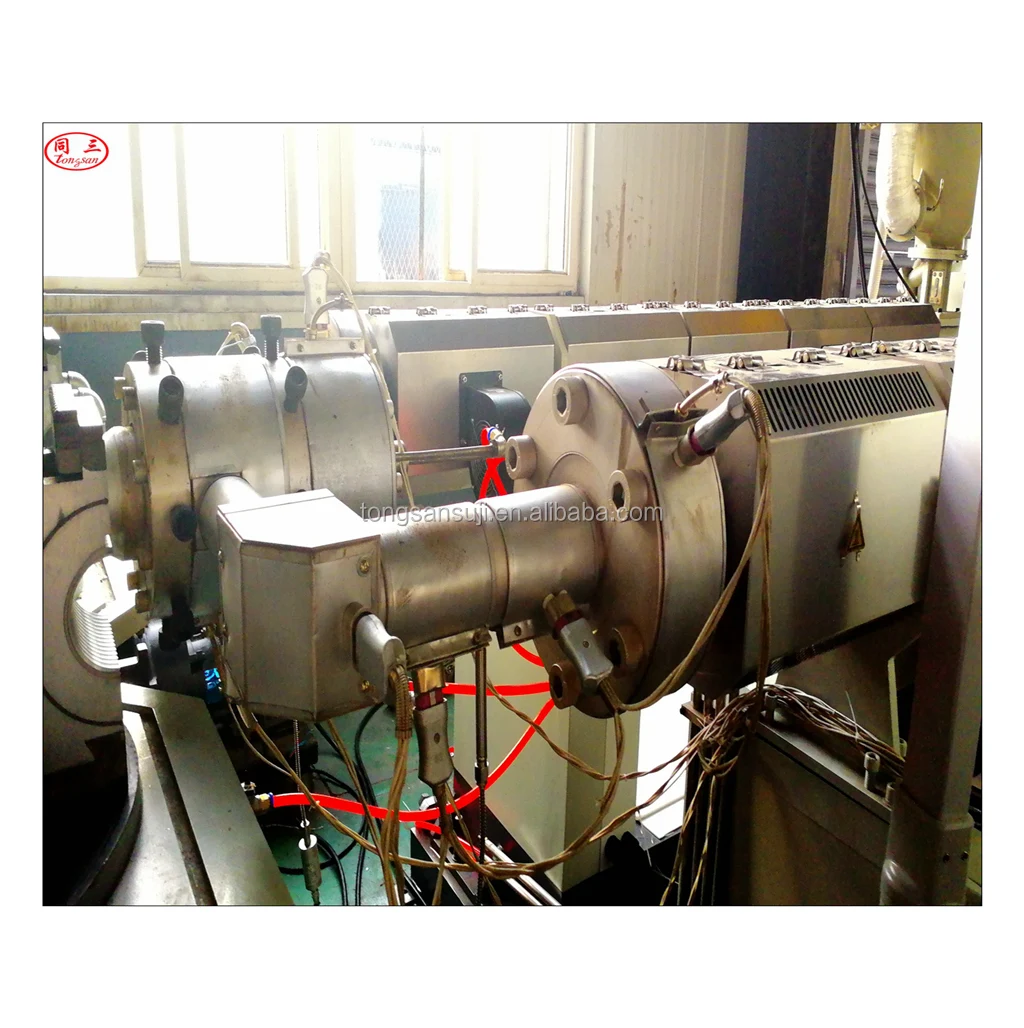

Extruder for Double wall corrugated DWC pipe machine

Die head

Mold blocks

Mold for DWC double wall corrugated pipe machine

Forming machine for DWC double wall corrugated pipe machine

Advantage of our Tongsan Plastic DWC double wall corrugated pipe machine

2. Composite extrusion die head with specially helical structure to make the wall thickness unifom and stable production.

3. The forming machine has automatic power-off protection device.The forming machine an antomatically exit from the die head to avoid equipment failure in case of electrucity cut off suddenly.It also equipped with new type high transmitting ratio reducer, easy to operate and mainteance.

4. The corrugated forming system is in combination with water cooling and air cooling to sensure high production speed

continuously.Advanced programmable lubricating system minimizes the moulds wear so as to increase the life of service and ensure work smmothly with high precision to ensure the products quality stability.

5. Mould adopts specialy alumium alloy material and high precision die casting forming mould method,it has the advanages of high precision,high stremgth,good wearability and better heat dissipation performance.

6. Wave structure launched a comprehensive new optimization design to reach the best combination of high-rigidity and low weight.

You need a product

You May Like

- Nearest port for product export

- Qingdao Port, China, Any port, China

- Delivery clauses under the trade mode

- FOB, CFR, CIF, EXW

- Acceptable payment methods

- T/T, L/C, Cash