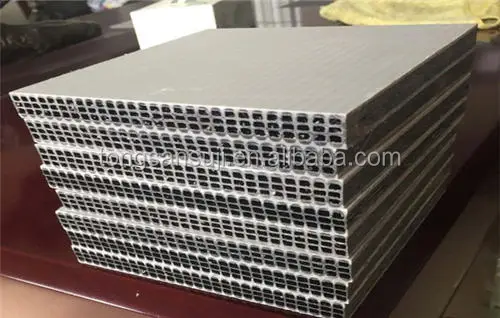

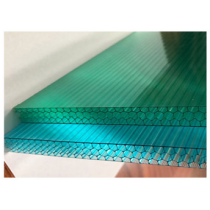

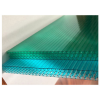

1220mm Plastic PP hollow Construction Formwork Building Template Board Making Machine by recycled PP material

group namePP Hollow Corrugated Sheet Extrusion Line

-

Min Order1 piece

brand nameHEGU

model1220mm

payment methodT/T, L/C, Cash

-

update timeWed, 19 May 2021 11:40:10 GMT

Packging & Delivery

Min Order1 piece

Briefing

Detailed

Plastic PP hollow Construction Formwork Building Template Making Machine by recycled PP material

Plastic PP hollow Construction Formwork Building Template Making Machine by recycled PP material

Models of Plastic PP PE PC hollow corrugated sheet extrusion line

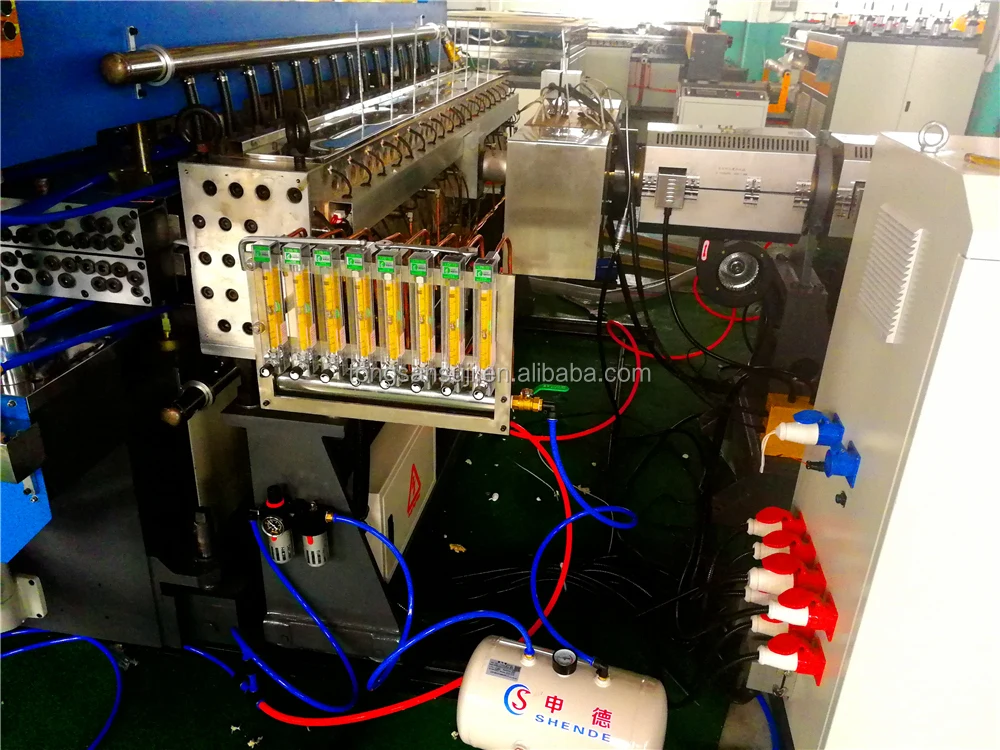

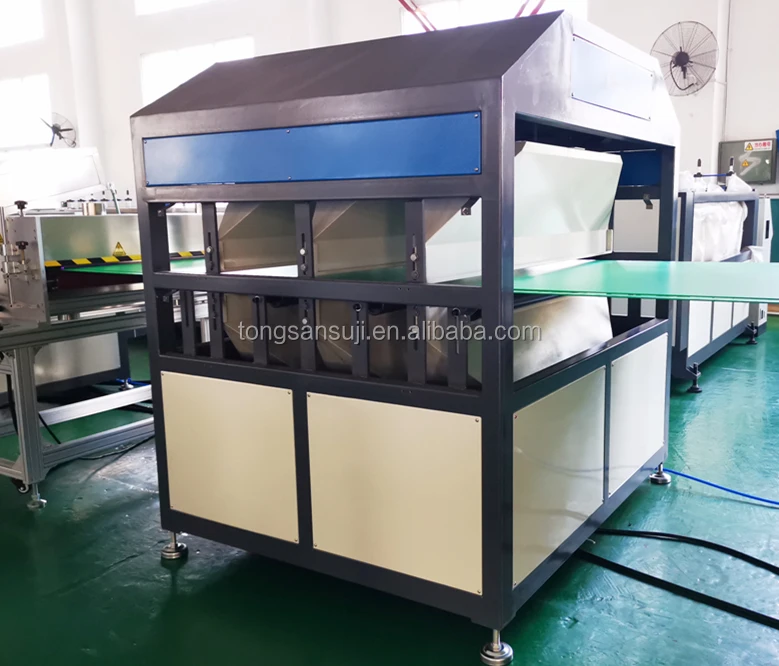

Auto feeder

Main extruder

Co extruder

Screen changer

Die head

Calibrators

1st haul off

heating oven

cooling device

Corona treatment

2nd haul off

Auto length cutting

You need a product

You May Like

- Nearest port for product export

- Qingdao Port, China, Any port, China

- Delivery clauses under the trade mode

- FOB, CFR, CIF, EXW

- Acceptable payment methods

- T/T, L/C, Cash