Automatic die cutting and creasing machine for making PP corrugated box from PP hollow sheet

- US $100000.00

1 - 5 piece

- US $95000.00

6 - 10 piece

- US $90000.00

11 - 20 piece

group nameCorrugated Box Making Machine

-

Min Order1 piece

brand nameHEGU

modelTS-1300

payment methodL/C, T/T

-

update timeWed, 19 May 2021 11:40:35 GMT

Paramtents

machine die cutting machine

auto grade full automatic

Packging & Delivery

Min Order1 piece

Briefing

Detailed

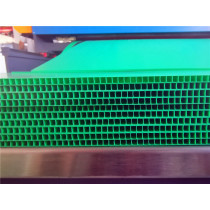

Automatic die cutting and creasing machine for making PP corrugated box from PP hollow sheet

DIE CUTTING DESIGN DRAWING

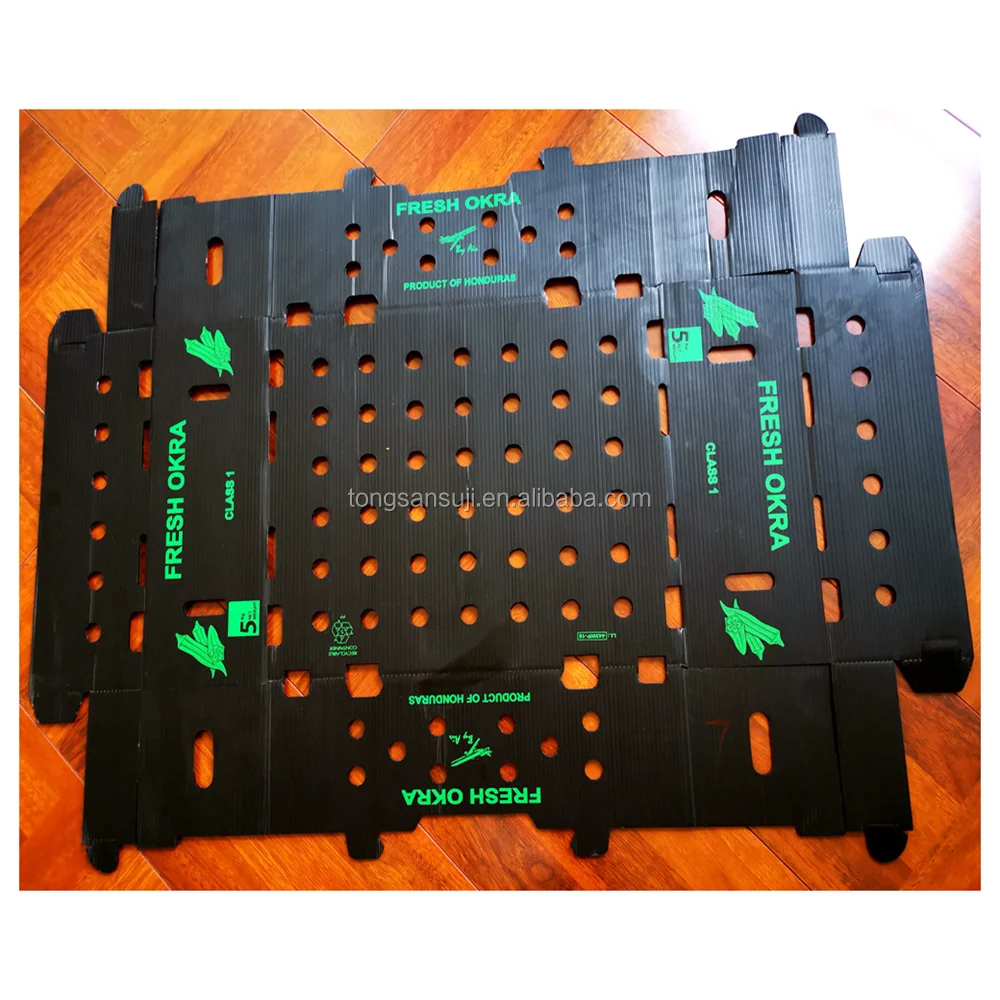

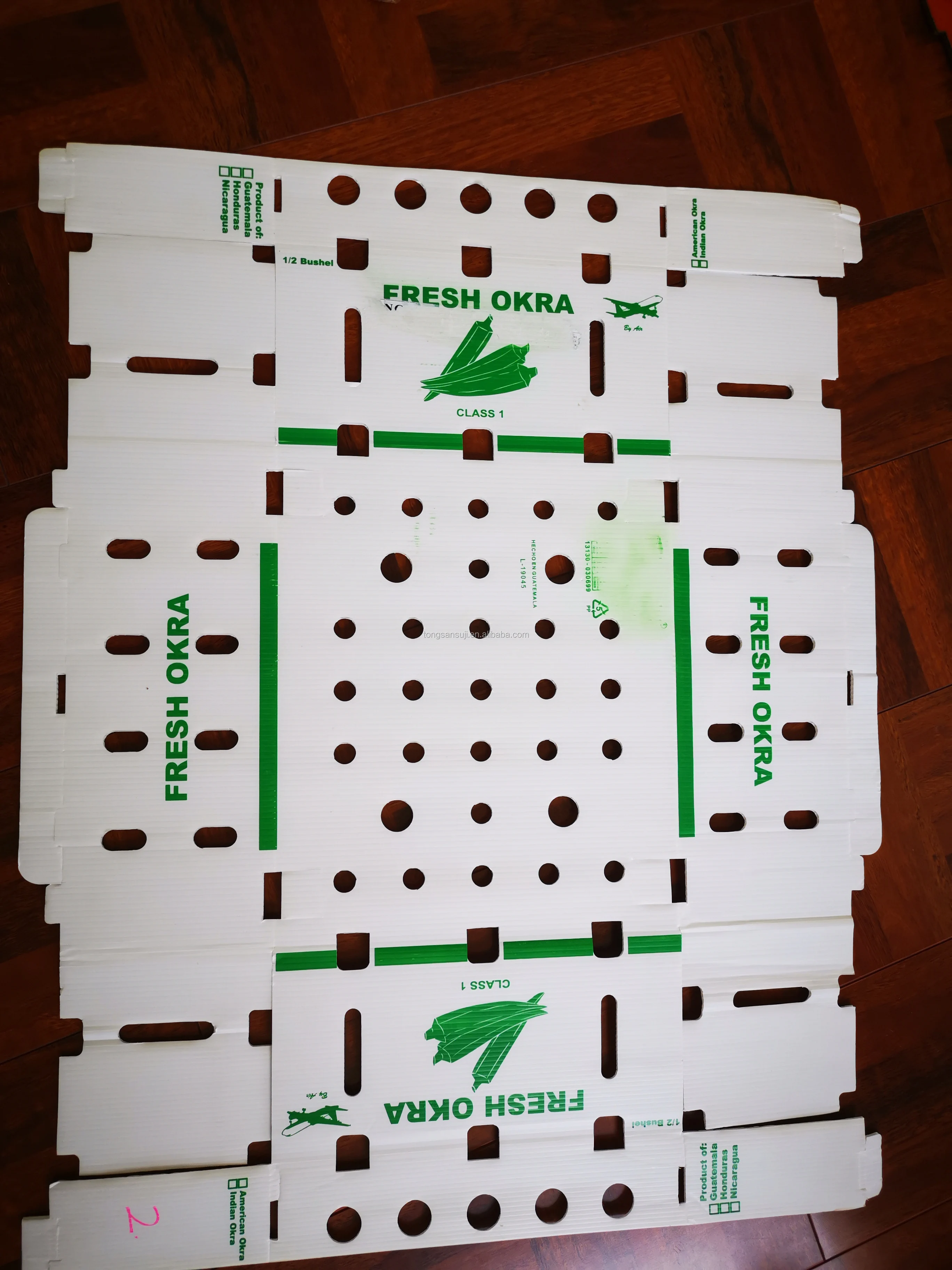

DIE CUTTING PP HOLLOW CORRUGATED SHEET

Detailed Technical parameters for Automatic die cutting and creasing machine for making PP corrugated box from PP hollow sheet

The worm gear material is made of high quality alloy copper, precision machine tool processing, hand scraping,High precision andparticularly wear resistant.The dynamic damping booster system makes the machine less wear and tear, more pressure. It adopts Japanese SMC rotary joint and is equipped with pneumatic clutch. It has low noise, long life and smoother braking.Equipped with automatic centralized lubrication system, the crank connecting rod of the main drive is forced to supply oil Electronic auxiliary chain brake system ensures stable stop at high speed rotation

(2) Transmission section

The intermittent box drive adopts Taiwan's professional ternary cam indexing mechanism, which makes the transmission noise smaller, the drive is more stable, and the maintenance and replacement is more convenient.

The tooth row body is made of high-quality hard aluminum alloy profile, the surface is anodized, the rigidity is strong, the

material is light, and the inertia is small, which can accurately convey the sheet process when telling the operation.

The main chain is made of original British RENOLD or German IWIS, which has good tensile strength.

The PLC controllable centralized chain oil supply system is equipped with an oil protection groove to make the machine more lubricated and clean.

PLC program-controlled automatic oil supply system, can complete the lubrication of the chain as needed

(3) Sheet feeding unit

High-precision Feida paper feeding, German Beck vacuum pump, equipped with super suction nozzle,Both cardboard and corrugated cardboard can be accurately fed.

The local area monitoring system can see the situation of the back delivery in real time when the paper is placed in front, which makes the machine operation safer.

HMI man-machine interface to monitor machine health at all times.User-friendly pneumatic pre-printing device design to make the cardboard more tidy.

Pre-disc fiber optic proofing can accurately prevent the paperboard from entering obliquely and reduce the waste of carton.

(4) Die cutting unit

Safe and flexible design of the rotating device makes the board adjustment board faster and more convenient

The frame is made of pneumatic lock plate, the protective beam and the lock nut are designed to make the template more stable.

The die-cut steel plate is made of 70Cr material, which is more durable; the upper part is provided with a floating air floating device, which makes the die-cutting board easy to enter and exit.

Die-cut protective window design, change the plate to take light more intelligent, make operation safer

(5) Waste cleaning unit

Three sides of waste, using a central positioning system, stripping template loading and unloading operations, accurate

Double-layer sports plate frame, upper and lower mold design is more convenient for all kinds of waste paperboard, and can be used without die-cutting die-cutting cam lifting design, which makes the scrapping more stable and fast.

Electric waste frame lifting device.

(6) Electrical parts

PLC and HMI control are used to realize automatic control and real-time detection of processes from paper feeding, paper feeding,die cutting and delivery.

The machine interface display system can display various working conditions in real time. When a fault occurs, the multi-tone speaker alarms and automatically stops, which truly guarantees the safety of human and machine.

Siemens main motor, Japan Fuji inverter, giving the machine output stable and reliable power

(7) Sheet collection unit

Double-eye detection in the delivery section, effectively preventing machine damage caused by paper drop, and making the delivery more stable

Pneumatic non-stop delivery sampling design, can test the die cutting accuracy of the sample without stopping the machine, you can use the interpolation counting function. Adopt Taiwan's Shan State two-speed geared motor to reduce the working frequency of the contactor and improve Empty plate speed, realizing efficient machine operation

You need a product

You May Like

- Nearest port for product export

- Qingdao Port, China, Any port, China

- Delivery clauses under the trade mode

- FOB, CFR, CIF, EXW

- Acceptable payment methods

- T/T, L/C, Cash