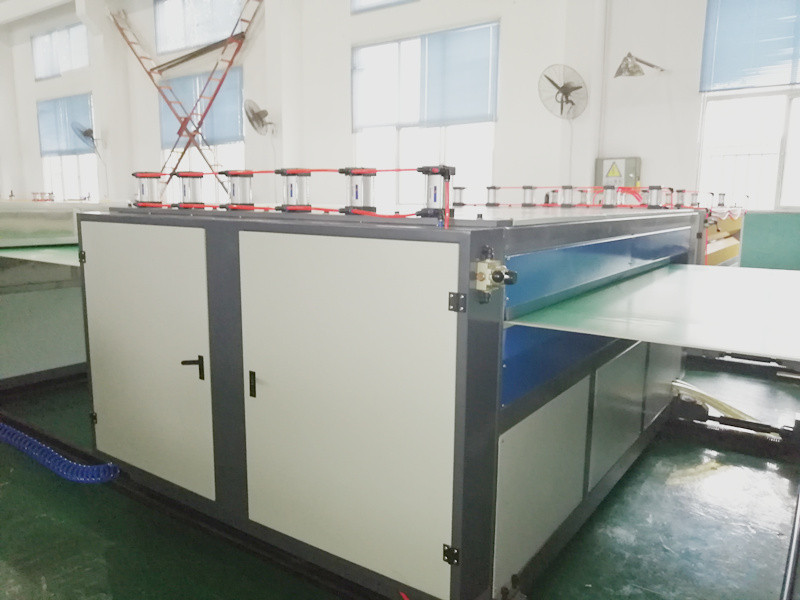

2100mm PP Polypropylene hollow corrugated sheet machine with co-extruder

group namePP PE PC Plastic Hollow Sheet Extrusion Machine

-

Min Order1 piece

brand nameQingdao Tongsan

payment methodL/C, Western Union, MoneyGram, T/T, Paypal

-

update timeFri, 22 Nov 2019 13:10:46 GMT

Paramtents

Sheet width 2100mm

sheet thickness 2mm-6mm

Main extruder SJMS120

Co-extruder SJMS80

Total power 480kw*60%

Production speed 0.3-6m/min

Production capacity 350-400kg/h

Brand Qingdao Tongsan

Packging & Delivery

Min Order1 piece

Briefing

Detailed

The main extruder can use recycled PP and fillers, and the surface co-extruder only needs to use new PP raw materials, so it is easy to maintain the smooth surface of the PP hollow corrugated board.

Regarding the cost, the cost can be easily reduced by using a co-extruder PP hollow board manufacturing machine.

Therefore, in order to maintain product quality and increase the competitive advantage of product repricing, it is a good choice to increase competitive advantage in product repricing.

1, Our advantage

A.22 years manufacturer for plastic extruder machines,

B.50 professional engineer

C,5Q Strict quality control with CE

D.20+ years Professional Foreign Trade Service

E,Free machine running

F,Turnkey project service

2,Quality is Our Culture

Since 1997,Qingdao Tongsan has been focusing on plastic extrusion machines .Now have the corrugated pipe machine serious,plastic hollow sheet machines,plastic pipe serious,plastic sheet serious.Our professional engineer always committed to the improvement of machine quality

3,Customer satisfaction is our pursue

All behaviors will be based on better and more considerately meeting the needs of consumer to offer customized service.

4,Turnkey Service Provider

Let customer experience a sense of entitle,respond within 24 hours,solve problem within 48 hours.We will work 24hours*7days for the after-sell service.

5,Pursuit of Excellence

Devoting to the research,development and production of various plastic extrusion machines.It is always making innovations and keeping up with the times.

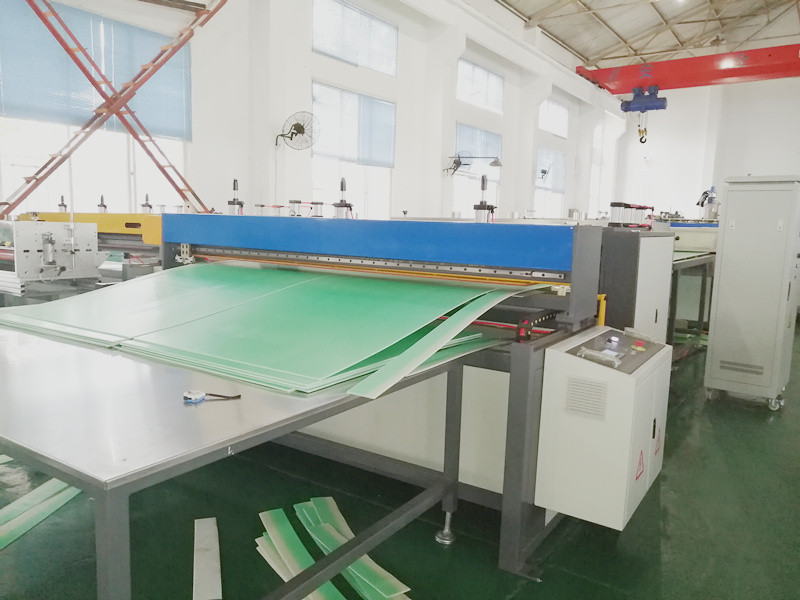

Our hollow corrugated sheet making machine can produce the sheet with the width of 1220-2450mm and thickness of 1.5mm-12mm.

The specially designed screw and the advanced controlling system ensure excellent plasticization,high output and stable extruding.We have the co-extrusion type to use the recycled plastic to reduce the cost with high quality products.

Mould adopts high-quality alloy steel and throttling device to ensure even pressure of feed influent at the mould lips,and also differential action of up-down piece guarantee even thickness of the plate.

Corona machiner

In order to improve the surface tension of the hollow sheet surface, and thereby improve the printing ink fastness, the hollow corrugated sheet surface will under corona treatment, so that the surface produces micro-concave dense holes, plastic surface roughening, increase the surface activity.

The second one is designed to remove stress,and in addition it is equipped with edge-cutting device to ensure the valid width and smooth cut of the edges.

Accurate instant length-fixed cutting and automatic up-down discharging system combined with alloy steel sharp blade realize high quality of cutting.

You need a product

You May Like

- Nearest port for product export

- Qingdao Port

- Delivery clauses under the trade mode

- FOB, CFR, CIF, EXW

- Acceptable payment methods

- T/T, L/C, MoneyGram, Credit Card, PayPal, Westem Union, Cash, Escrow