2100mm PP Hollow corrugated box sheet making machine

- US $160000.00

1 - 1 piece

- US $159000.00

2 - 2 piece

- US $158000.00

3 - 3 piece

group namePP PE PC Plastic Hollow Sheet Extrusion Machine

-

Min Order1 piece

brand nameQingdao Tongsan

payment methodL/C, Western Union, MoneyGram, T/T, Paypal

-

update timeTue, 17 Dec 2019 13:57:44 GMT

Paramtents

Production capacity 260-300kg/h

Production speed 0.3-6m/min

Main extruder model SJ120/36

Raw material pp/pe granules ,filler masterbatch

Packging & Delivery

Min Order1 piece

Briefing

Detailed

PP Plastic is dedicated to improving the quality of hollow plate, research and development of plastic hollow plate deep processing. develop different processes according to different products. Made of indoor and outdoor advertising exhibition display board, publicity posters, dairy drinks and wine display box and other products, this product has waterproof and moisture-proof, anti-aging, exquisite printing, long use time, beautiful and generous, overall vision and other characteristics.

Characteristics and market advantages:

1, PP hollow sheet is mainly used in various fields of electronics, packaging, machinery, light industry, postal services, food, medicine, pesticides, home appliances, advertising, decorating, stationery, magneto-optical technology, bioengineering medicine and health. It is a new type of environmentally friendly packaging materials.

2, PP hollow board is a green material with a very wide range of applications, and gradually replace some of corrugated paper packaging materials, and now some domestic enterprises are also being developed for building decoration materials. because of its wide range of applications, easy to use, PP hollow sheet also has been called as “Universal board”, which is widely used in advertising background, stationery materials, industrial packaging, products such as earthquake, the most common products like turnover box, removable combo box, finished packaging Boxes and boxes in the partition. PP hollow sheets are generally made of environmentally friendly non-polluting recyclable thermoplastic polypropylene (PP), polyethylene (HDPE) resin and a variety of accessories made of the other there is a polycarbonate (PC) PP hollow sheet, also known as sunshine board, Long board, PC hollow board, is a high-performance engineering plastics PC resin processing, with high transparency, light weight, impact resistance, noise, heat insulation, flame retardant, anti-aging characteristics, is a high-tech, integrated Extremely superior performance, energy saving and environmentally friendly plastic sheet

3, PP hollow sheet standardized products can be reused many times, can bring huge social and economic benefits, making the plate less than one-tenth of the cost of disposable tray, but also can improve the volume of loading and inventory utilization, Improve logistics efficiency, significantly reduce logistics costs. At the same time, the General Office of the State Council forwards the notice of the NDRC and other departments on accelerating the conservation and substitution of timber. It explicitly requires that all industries speed up the implementation of timber conservation and substitution technologies and make green Environmentally friendly products.

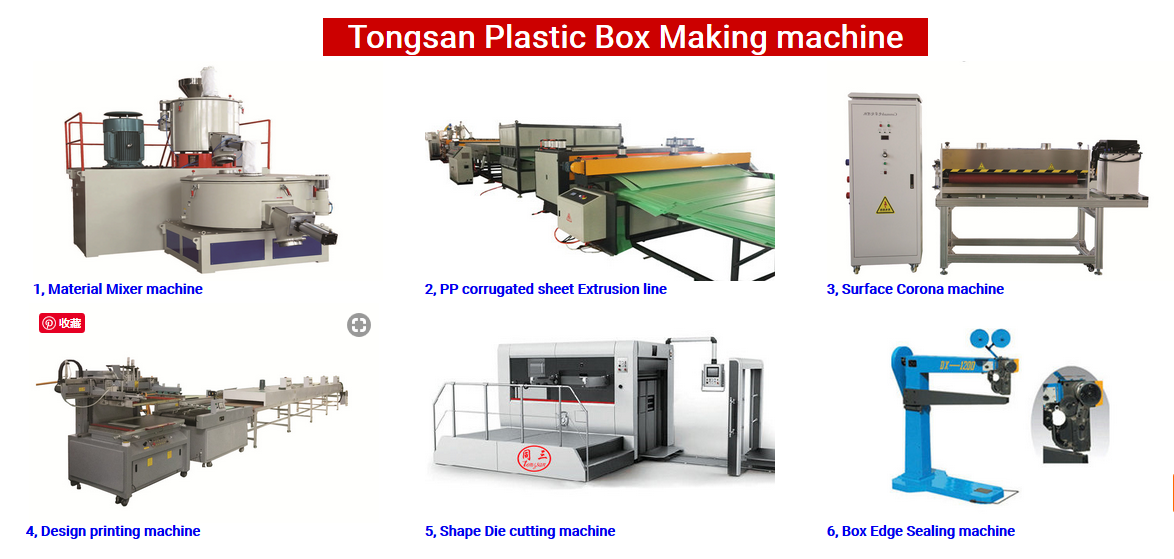

How to make the PP corrugated hollow box for packaging

PP hollow sheet turnover box main material is a PP hollow sheet, and then after the pressure cut, torn edges, stitching, assembly and made of a series of processing flow.

Below is the example of processing for turnover box

1, the extrusion line produce the required PP hollow sheets with required width and thickness, and cut into required length. And collecting different sizes in different stacking.

2,Use the pressure cutting machine to cut the PP hollow sheet into required shape. Pressing action should be accurate, rapid, agile, and keep the board clean, in accordance with the provisions of a unified placed on the table

3, the professional workers tear the extra edges according to the indentation from the pressure cutting machine, The tearing action should pay attention to the intensity. to ensure the board neat appearance, it is not allowed to produce flash and laceration because of strong tearing force.

4, stitching the two sheets by rivets, flat wire or welding, etc., the stitching seal can be sealed by fiber tape or glue or magic paste.

5, quality inspection. Quality inspection staff to perform full inspection, sampling, failure and other standard scrap process.

6, the qualified products will be packaged and stored, when folded, the packing box should be labeled and neatly put into storage.

The above is the whole process of making the turnover box from the PP hollow sheet. The turnover box made from PP hollow sheet has the advantages of light weight, non-toxic, tasteless, no pollution, flexural resistance, anti-aging, waterproof, moisture proof, abrasion resistance, corrosion resistance, , Can be reused repeatedly and a series of advantages, is a new type of green materials, logistics and packaging industry in the transport plays an important role in storage and turnover, can effectively protect the product from the external environment damage

You need a product

You May Like

- Nearest port for product export

- Qingdao Port

- Delivery clauses under the trade mode

- FOB, CFR, CIF, EXW

- Acceptable payment methods

- T/T, L/C, MoneyGram, Credit Card, PayPal, Westem Union, Cash, Escrow