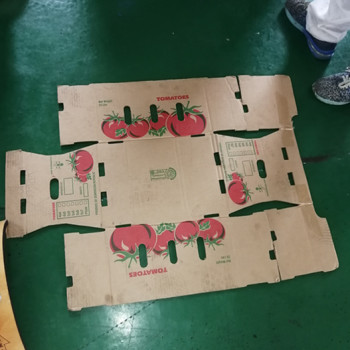

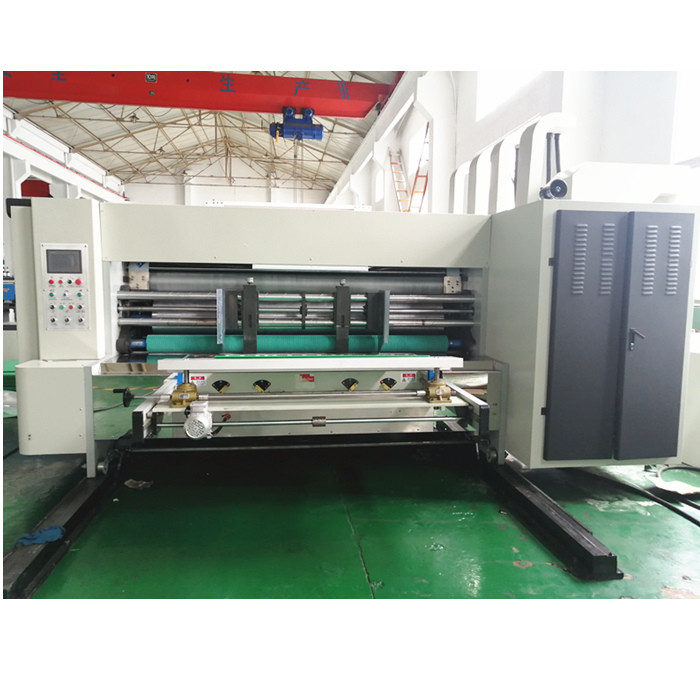

Plastic corrugate sheet high speed double color printer for fruit box making

group namePlastic hollow sheet box making auxiliary machine

-

Min Order1 piece

brand nameQingdao Tongsan

payment methodL/C, Western Union, MoneyGram, T/T, Paypal

-

update timeThu, 24 Sep 2020 13:18:11 GMT

Paramtents

Maximum sheet size 2400×1450mm

Minimum machining size(L×W). 340*400mm

Printing plate thickness 7.2mm

Suitable sheet thickness 1.2-12mm

Maximum mechanical speed 150pcs/min

Main motor power 11kw

Color accuracy Two colors ±0.25mm

Packging & Delivery

Size500cm x 500cm x 500cm

Weight12000.00kg / piece

Min Order1 piece

Briefing

Detailed

Tongsan High speed double color printer

Main mechanical properties:

This product can complete the two-color printing, cutting, indentation, trimming, slotting, die cutting and other processes of paperboard at one time. Taiwan roller front positioning automatic paper feeding mechanism, adjustable air volume, main frequency conversion control. This machine adopts PLC and color display screen to control the machine with multi-function, which is convenient, fast and flexible. Phase adjustment through digital display electric adjustment, automatic zeroing, automatic reset; transmission gear adopts 40CrMnTi high quality alloy steel, material Carburizing and quenching, fine grinding; the main transmission gear and transmission shaft are connected by increasing tension and key, so that the virtual position is magnified, the wear of the center is eliminated, and the printing press is kept. Long life overprint accuracy; the whole machine adopts electric separation, pneumatic locking, single machine tight combination, overprint does not leave position; the machine has the characteristics of accurate color, exquisite printing pattern, convenient use and maintenance, high degree of automation and so on.

Our service

1,We have all series plastic hollow corrugated sheet making machine in production,warmly welcome to visit our factory for machine running.The machine running is the best prove of the machines' quality ,the good quality machine is the granulating for the high effective production.

2,We can testing the machine according customer's formula.One is the customer can inspect the quality of our machine,another is the customer can check the quality of the products,so it is easy to calculate the cost of the sheet and the production capacity of our machines.So it's easy to calculate the investment pay back and increase the feasibility of the project.

3,We are professional for the auxiliary machine for sheet raw material making and plastic boxes making.We can provide the plastic filler masterbatch granulating making machine,the wast sheet crusher,the raw material mixing machine,the die cutting machine,the corona treatment machine,the sheet printing machine,the welding / bookbind machine .

4,Our engineer oversee installation and debugging ,our engineer with rich experience and will teach customer's worker about the operating one by one.And we provide long life time technical support.

Item | Parameter |

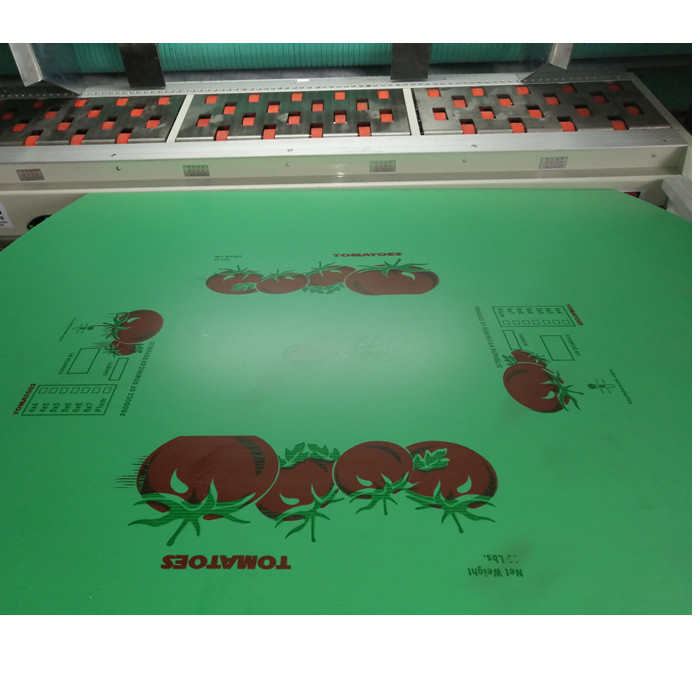

1Printing roller (Plate roll) | 1) OD=Ø444mm。 2) Grinding of steel pipe surface with hard chromium plating 3) Balance correction, smooth operation. 4) Ratchet fixed reel shaft. 5) The full version of the hanging plate shall be of 10mm and 3mm hanging strip. 6) With fast plate changing device, loading and unloading printing plate is convenient and fast, with pedal switch electric control forward and reverse turn. |

2 Printing roller | 1) OD=Ø156mm ,thickness=18mm 2) Grinding of steel pipe surface with hard chromium plating 3) Make balance correction and run smoothly. 4) Manual adjustment range of printing roller clearance dial 1.2~12mm |

3 Paper feeding up and down roller | 1) Upper roll: the outer diameter is 86mm thick-wall steel pipe, with three outer diameters and 120mm paper feeding rings. 2) Lower roll: outer diameter is 156mm thick-wall steel pipe, surface grinding, hard chromium plating. 3) Manual adjustment of paper roller gap dial, adjustment range 1.2~12mm |

4 Steel mesh roller | 1) OD=Ø198.8mm,thickness=22mm 2) Steel pipe surface grinding, pressing mesh, hard chromium plating. 3) Make balance correction and run smoothly. 4) The number of mesh is 180200220.250 mesh, etc., optional. 5) Cooperate with the pneumatic automatic lifting device of the paper feeding system (the mesh roller drops in contact with the printing plate during paper feeding, and stops the screen roller rising and printing plate separation during paper feeding). 6) The mesh roller is equipped with a wedged overrunning clutch, which is convenient and quick to wash ink. |

5 Rubber roller | 1) ID=Ø198.8mm。 2) The surface of the steel pipe is coated with wear-resistant rubber and the balance correction is made. 3) The rubber is high in special grinding, and the ink transfer effect is good. |

6 Phase adjusting mechanism | 1) The structure of the planet gear. 2) The printing phase is adjusted by electric digital 360 °phase meter. (operation, stop can be adjusted) 3) Manually adjust the transverse position and adjust the distance ±7.5mm 4) Automatic memory reset system after cleaning printing plate in printing process |

7 Ink circulation | 1) The pneumatic diaphragm pump has the advantages of stable ink supply and simple operation and maintenance. 2) Ink filter, filter impurities, ink separation. |

8 Printing phase fixing device | 1) Cylinder type automatic brake device 2) When the machine is separated or adjusted, the brake mechanism limits the rotation of the machine and maintains the fixed point of the original gear position. |

You need a product

You May Like

- Nearest port for product export

- Qingdao Port

- Delivery clauses under the trade mode

- FOB, CFR, CIF, EXW

- Acceptable payment methods

- T/T, L/C, MoneyGram, Credit Card, PayPal, Westem Union, Cash, Escrow