2100mm Co-extrusion plastic PE hollow corrugated sheet extrusion line

group namePP PE PC Plastic Hollow Sheet Extrusion Machine

-

Min Order1 piece

brand nameQingdao Tongsan

modelTSSJ120

payment methodL/C, Western Union, MoneyGram, T/T, Paypal

-

update timeFri, 22 Nov 2019 12:57:31 GMT

Paramtents

Sheet width 2100mm

Sheet thickness 2mm to 12mm

Main extruder SJ120/36

Co-extruder SJ65/132

Production speed 0.3-6m/min

Production capacity 170kg/g-260kg/h

Packging & Delivery

Weight22000.00kg / piece

Min Order1 piece

Briefing

2, competitiveness sheet with good quality

3,easy operate can high output

Detailed

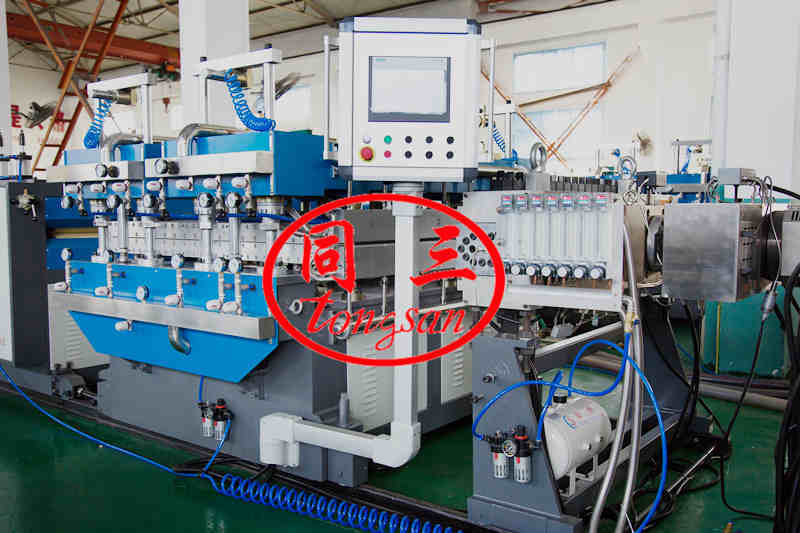

Machine name | Quantity | |

1 | Material mixing machine | 1 set |

2 | Single screw extruder | 1 set |

3 | Single screw co-extruder | 1 set |

4 | Screen changer | 1 set |

5 | Co-extruder mold:ABA | 1 set |

6 | Calibrating machine | 1 set |

7 | Six-pairs haul off machine 1st | 1 set |

8 | Preheating Oven | 2 sets |

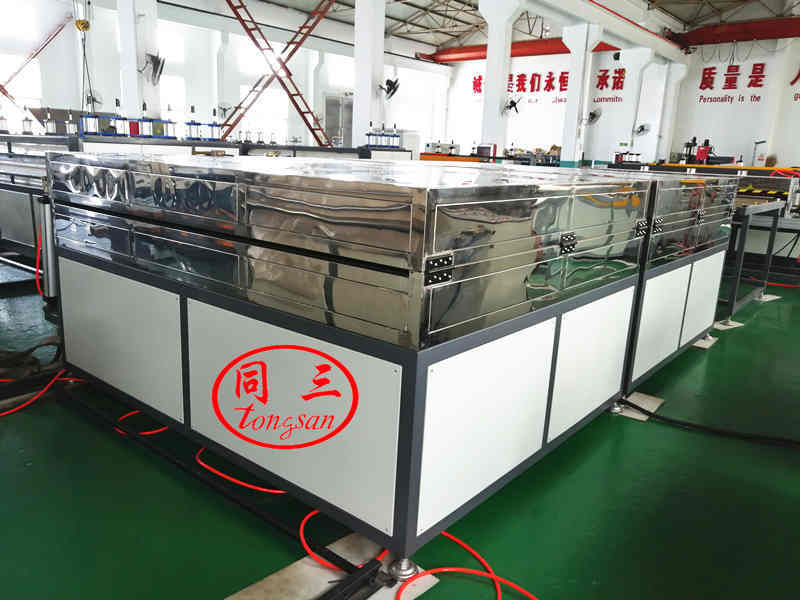

9 | Cooling device | 1 set |

10 | Corona treatment device | 1 set |

11 | Edge cutting device | 1 set |

12 | Three-pairs haul off machine 2nd | 1 set |

13 | Transverse cutting machine | 1 set |

14 | Stacker | 1 set |

The production line adopting the co-extrusion mode,so the recycled material (80 %-90 %) can be used in the middle, and new material can be used for the surface. The product has smooth surface which no visible difference to the naked eye, so it can reduce a lot of costs.

The mold adopt special steel which made with Italian formula technology ,it has the characteristics of memory rebound.The mold is more wear-resistant and the service life is several times longer than ordinary mold.

One set mold can produce different thickness range ,such as 2mm-5mm,5mm-8mm,8mm-12mm,just by change the center of the mold.

The screen changer adopt silk screen circulation, altogether 4 pcs silk screen, 3 normal use, 1 standby . It does not need to stop when changing the silk screen .

There are 6 rollers on the front haul off machine and 3 rollers on the second haul off machine ,so the production line is more stable.

The haul off machine adopt helical gear

The haul off machine and the calibrating platform are on the same guide rail for convenient synchronous alignment adjustment.

We adopt fan cooling style, the cooling speed can be fast.So it won’t shrink after cutting, it can effectively reduce the error.And the speed of production can be more fast.

The oven’s material is 201# stain steel,there are total 4 meters with two 2 meter oven.The customer can choose to use one or two according the product need.

You need a product

You May Like

- Nearest port for product export

- Qingdao Port

- Delivery clauses under the trade mode

- FOB, CFR, CIF, EXW

- Acceptable payment methods

- T/T, L/C, MoneyGram, Credit Card, PayPal, Westem Union, Cash, Escrow