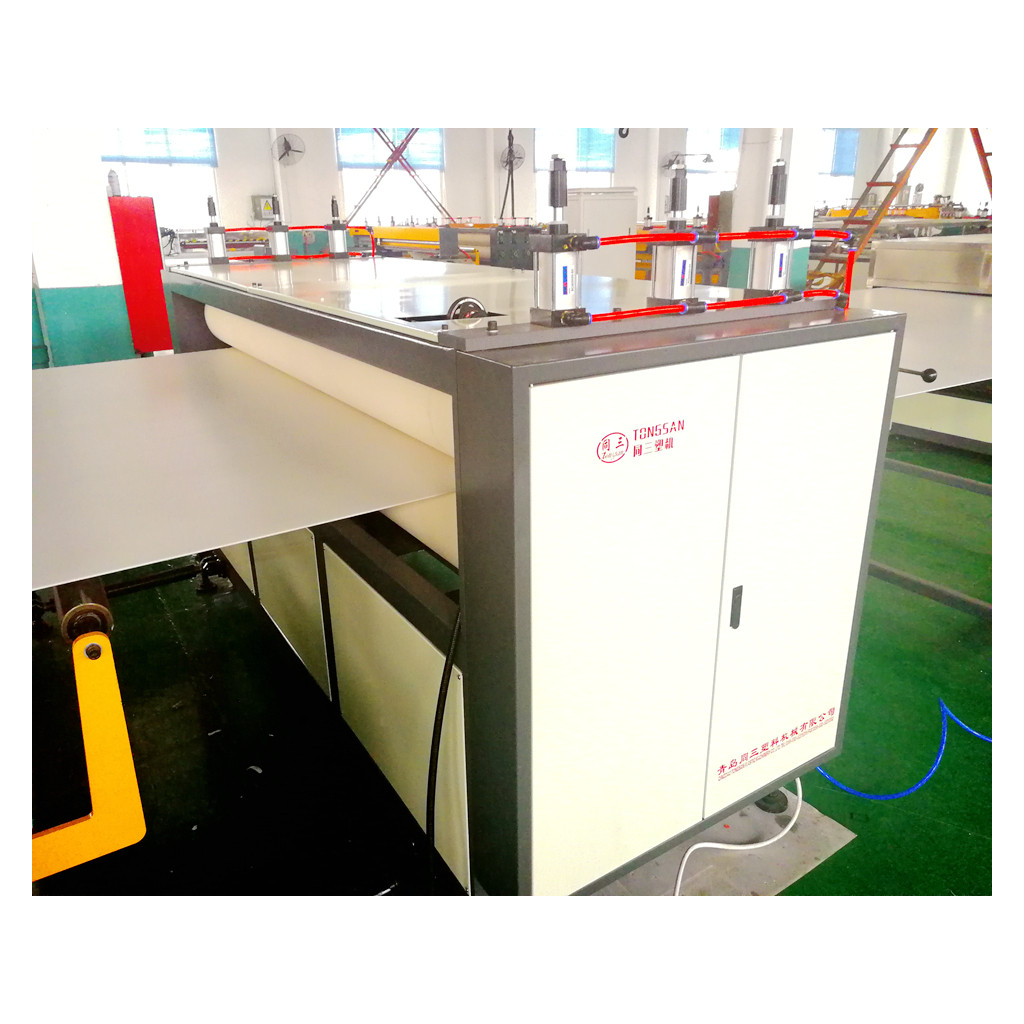

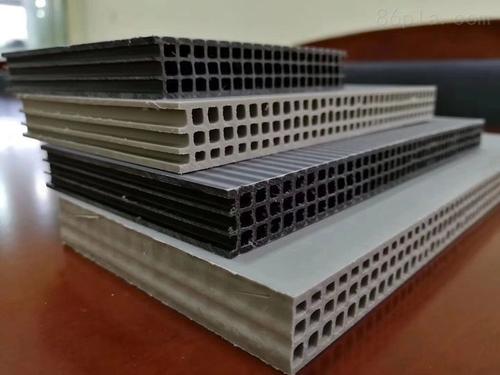

1200mm PP hollow board plastic building template making machine

group namePP PE PC Plastic Hollow Sheet Extrusion Machine

-

Min Order1 piece

brand nameQingdao Tongsan

payment methodT/T, L/C, MoneyGram, Credit Card, PayPal, Westem Union, Cash, Escrow

-

update timeSun, 27 Sep 2020 16:05:20 GMT

Packging & Delivery

Min Order1 piece

Briefing

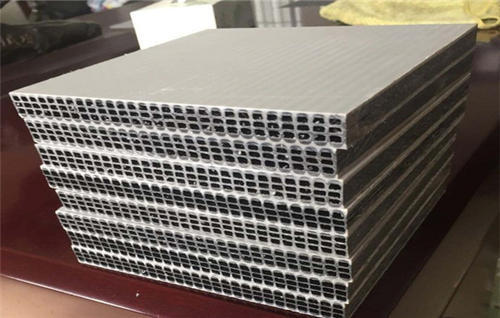

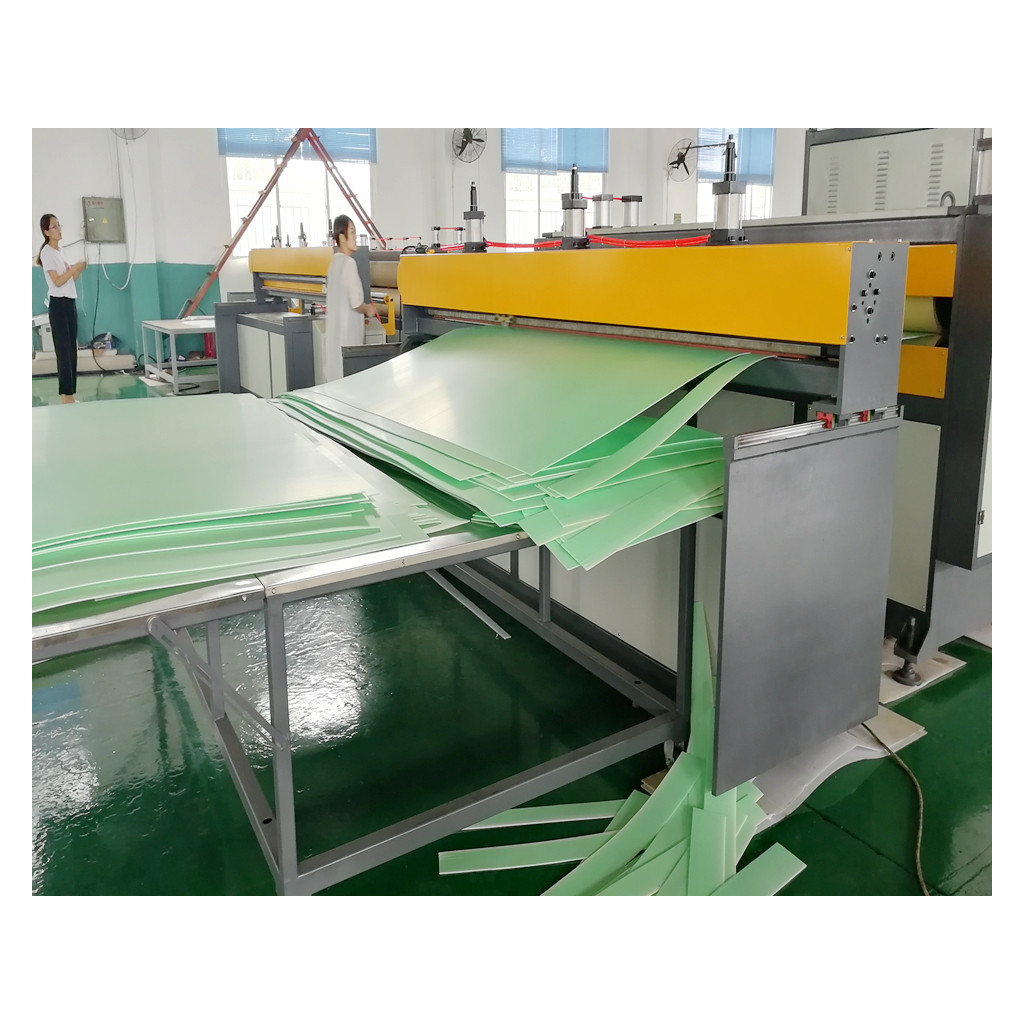

1,width: 1220mm, thickness:12-18mm

2,low cost and high quality

Detailed

|

Product material

|

Recycled PP material

|

|

Product width

|

1220mm

|

|

Product thickness

|

12-18mm

|

|

Product application

|

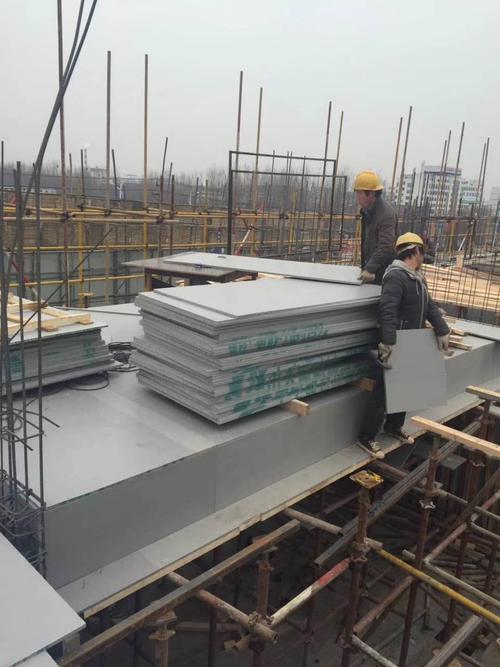

construction formwork, building template

|

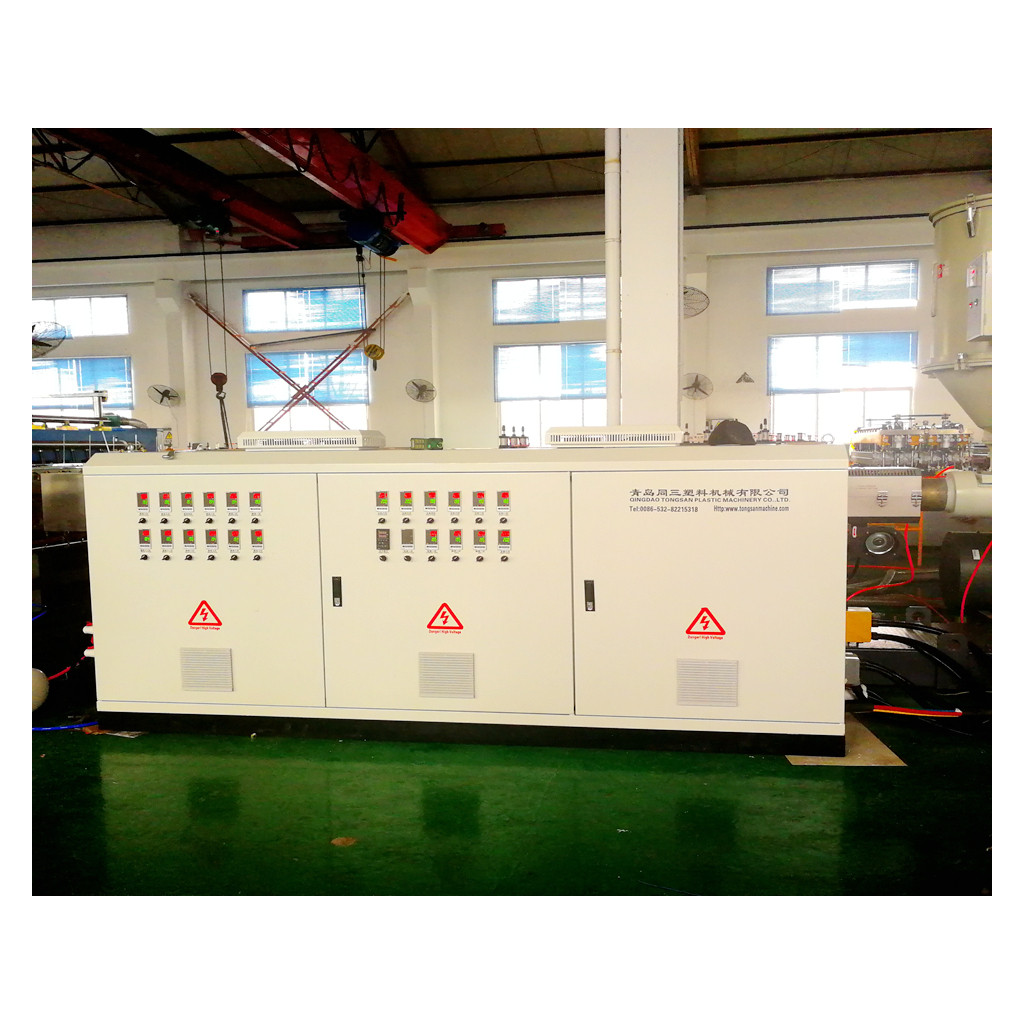

Extruder model | SJ100/36 |

Extruder Power | 75kw |

Extrusion capacity | 300-400kg/h |

Machine price | 120000-160000 USD |

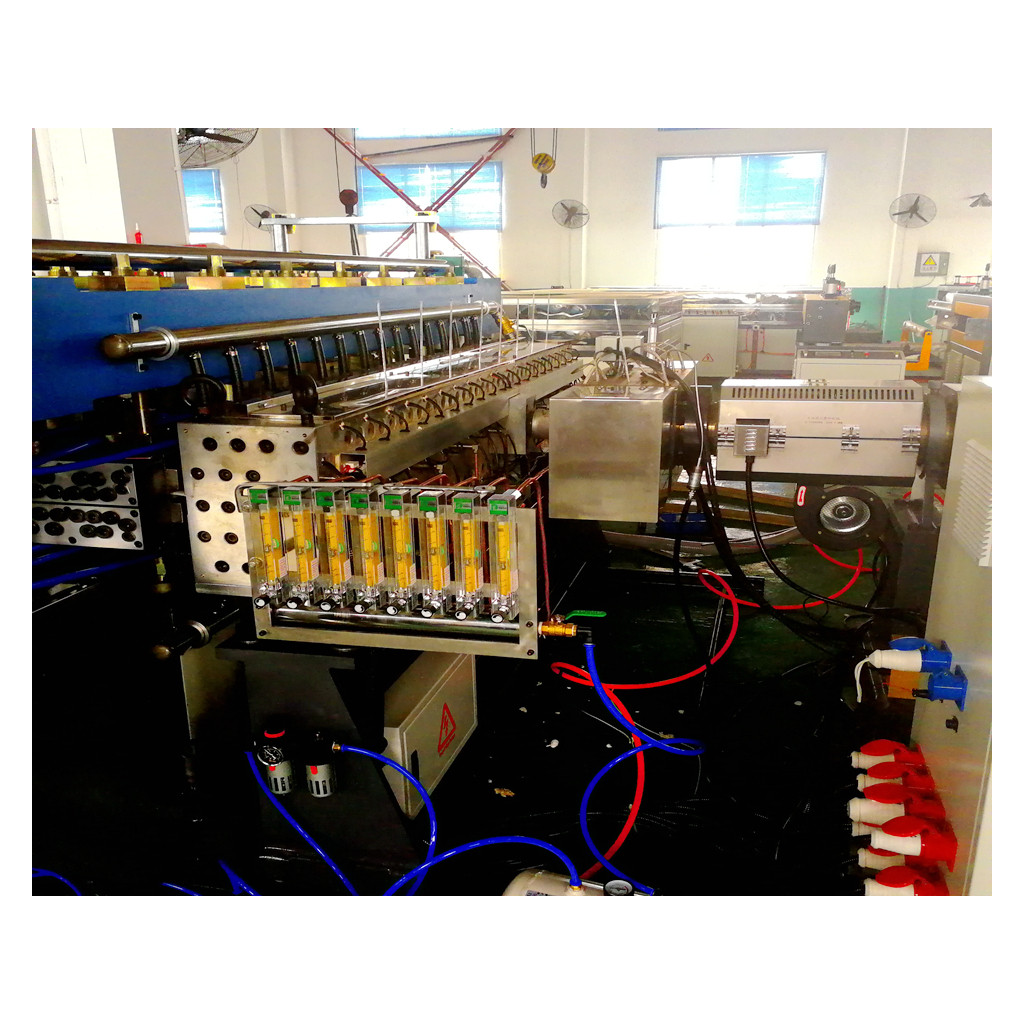

Die head | T shape die head |

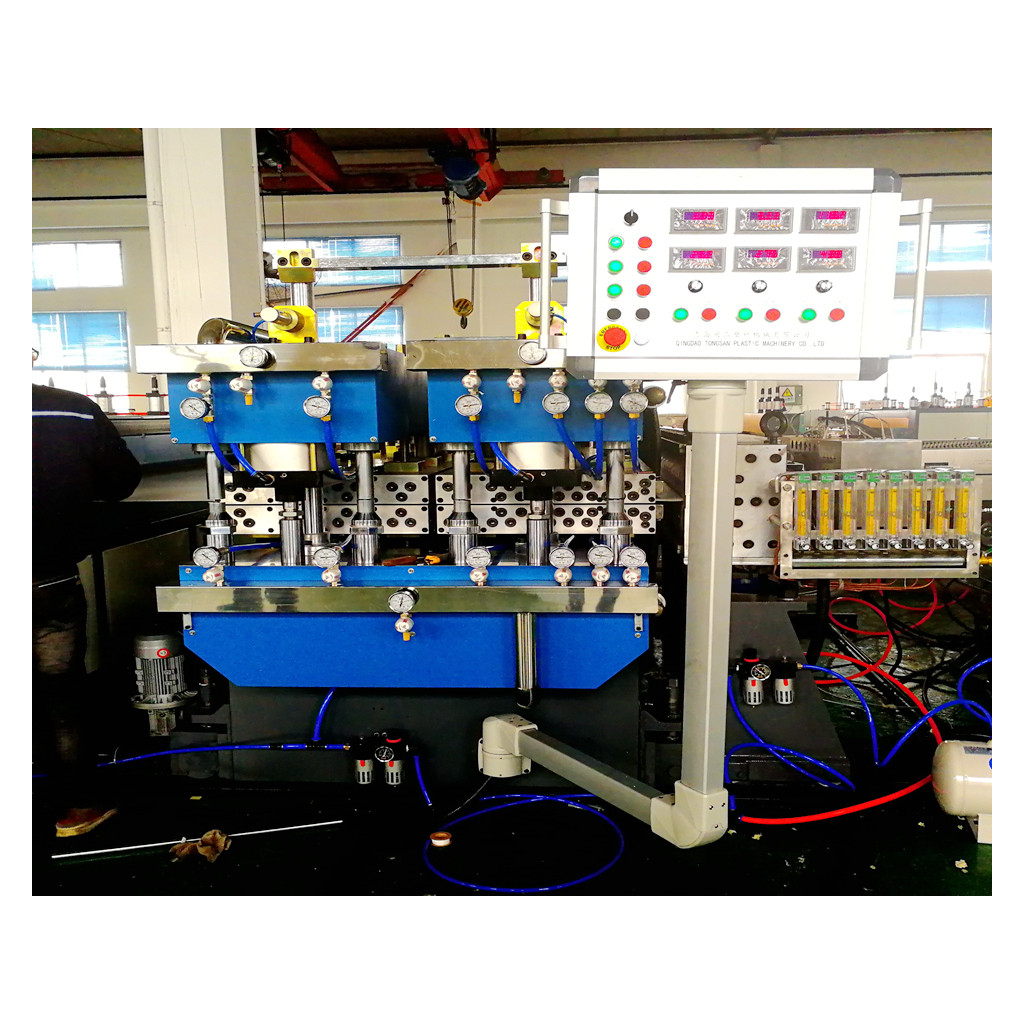

Calibrartors | Vacuum forming, 3 calibrators |

1st haul off | 6-8 pairs of roller |

heating oven | 4 meters |

2nd haul off | 3-4 pairs of roller |

Cutting device | Automatic cutting machine |

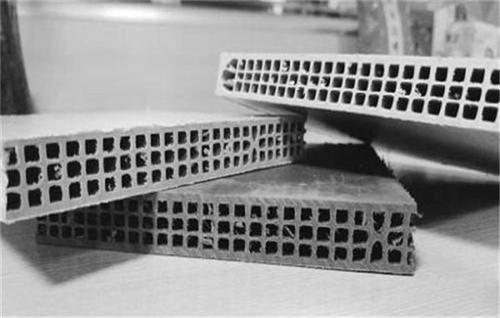

1. High economic benefits and low average cost: a new set of hollow plastic templates can be reused more than 50-100 times, the turnover rate is several times or even ten times that of high-quality wood templates, and the average cost is low.

1. Convenient, simple and efficient construction: The new hollow plastic formwork system is easy to match the molds, and can be dismantled manually without the help of mechanical equipment (only a wrench or a small hammer is required, and the labor intensity is low). The system design is simple and the workers can speed up, Quickly flip templates. Skilled installers can install 50-75 square meters per person per day, which greatly saves labor costs (compared with steel molds: only 50% of steel mold installers are required, no skilled workers are needed, only Construction workers do some simple training before installation).

3. The surface of the concrete is good after demoulding, which reduces the overall cost: After the new hollow plastic formwork is used, the quality of the concrete surface is smooth and smooth, which can meet the requirements of fresh concrete. No plastering (or thin plastering) is needed, which can save plastering costs. . At the same time, the workload of masonry, chiseling, closing and wet operations is reduced, the degree of civilization is high, and the overall cost is greatly reduced.

4. Reduce the use of large equipment: The new hollow plastic formwork uses trucks only when entering and leaving the site. It can be transported manually without the cooperation of cranes and tower cranes, which improves the overall production efficiency of the project, reduces potential safety hazards, does not rust, and has no potential fire hazards.

5. Low carbon emission reduction and high recycling value: The new hollow plastic template is recyclable and can be reused. After dismantling, there is no garbage on the site (no formwork joints, no leakage), the construction environment is safe, clean, and meets the requirements of building energy saving, environmental protection, low carbon, and environmental protection. After the template is discarded, when the residual value of the waste treatment is high, the cost sharing advantage is obvious (the recovery rate is about 30% -50%).

6. Standards and strong universality: The new plastic formwork can be customized to the required type, shape and specifications according to the requirements of the construction project to meet the needs of various buildings. Even standard boards can be cut at any time. cut.

With the spread of the advantages of new hollow plastic formwork, more and more construction sites have begun to choose this new type of building material product for building construction. The commercial value of hollow plastic formwork is irreplaceable!

You need a product

You May Like

- Nearest port for product export

- Qingdao Port

- Delivery clauses under the trade mode

- FOB, CFR, CIF, EXW

- Acceptable payment methods

- T/T, L/C, MoneyGram, Credit Card, PayPal, Westem Union, Cash, Escrow