1200mm pp pe pc plastic corrugated board making machine

group namePP PE PC Plastic Hollow Sheet Extrusion Machine

-

Min Order1 piece

brand nameQingdao Tongsan

modelTSSJ120

payment methodL/C, Western Union, MoneyGram, T/T, Paypal

-

update timeFri, 22 Nov 2019 12:56:55 GMT

Paramtents

Sheet width 1200mm

Sheet thickness 2mm to 12mm

Main extruder SJ100/36

Production speed 0.3-6m/min

Production capacity 170kg/g-200kg/h

Packging & Delivery

Weight22000.00kg / piece

Min Order1 piece

Briefing

Detailed

Qingdao Tongsan hollow corrugated sheet making machine can produce the sheet with the width of 1220-2450mm and thickness of 1.5mm-12mm.

Our service

1,We have all series plastic hollow corrugated sheet making machine in production,warmly welcome to visit our factory for machine running.The machine running is the best prove of the machines' quality ,the good quality machine is the granulating for the high effective production.

2,We can testing the machine according customer's formula.One is the customer can inspect the quality of our machine,another is the customer can check the quality of the products,so it is easy to calculate the cost of the sheet and the production capacity of our machines.So it's easy to calculate the investment pay back and increase the feasibility of the project.

3,We are professional for the auxiliary machine for sheet raw material making and plastic boxes making.We can provide the plastic filler masterbatch granulating making machine,the wast sheet crusher,the raw material mixing machine,the die cutting machine,the corona treatment machine,the sheet printing machine,the welding / bookbind machine .

4,Our engineer oversee installation and debugging ,our engineer with rich experience and will teach customer's worker about the operating one by one.And we provide long life time technical support.

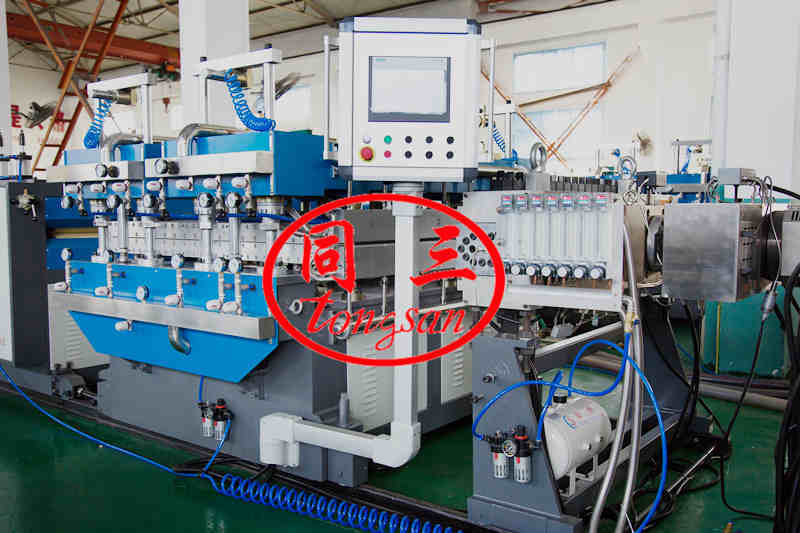

Machine name | Quantity | ||||

1 | Material mixing machine | 1 set | |||

2 | Automatic drying and feeder | 1 set | |||

| Single screw extruder SJ100 | 1 set | |||

4 | Screen changer | 1 set | |||

5 | Co-extruder mold:ABA | 1 set | |||

6 | Calibrating machine | 1 set | |||

7 | Six-pairs haul off machine 1st | 1 set | |||

8 | Preheating Oven | 2 sets | |||

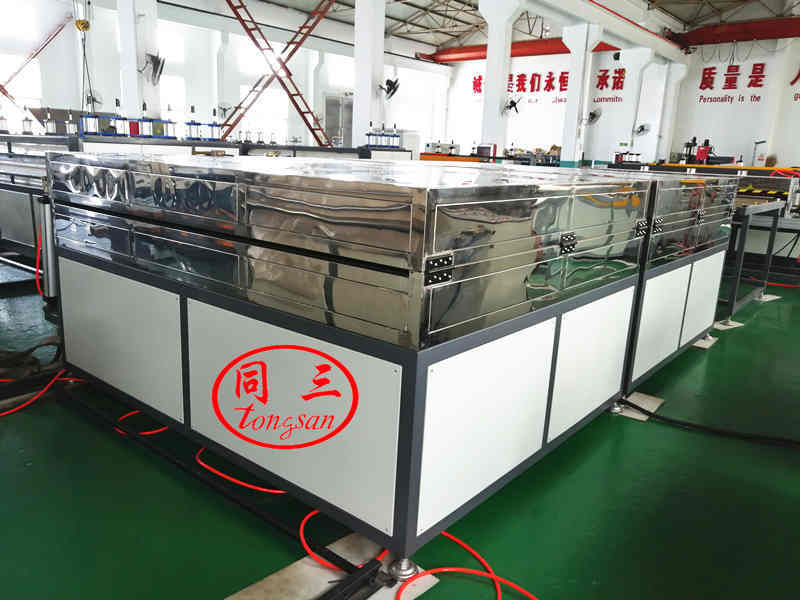

9 | Cooling device | 1 set | |||

10 | Corona treatment device | 1 set | |||

11 | Edge cutting device | 1 set | |||

12 | Three-pairs haul off machine 2nd | 1 set | |||

13 | Transverse cutting machine | 1 set | |||

14 | Stacker | 1 set |

Qingdao Tongsan Plastic Machinery co.,td have been develop the PP hollow corrugated sheet making machine since 2015,now we have the machines for the PP hollow grid plate width from 1220mm to 2450mm and thickness from 1.5mm to 12mm.

We have different model production line,such as the 1400 type PP hollow sheet extruder machine,1860 type PP corrugated sheet production line,2300 type PP hollow corrugated board making machine,2600type plastic hollow grid panel making machine,and for each model,we have the co-extrusion type for customer choose.

The co-extruder type can use 20%-60% fillermatch for reduce the cost,so our customer can product the cost competitiveness sheet with good quality.Our machine have the advantage of high output,easy operation,high precision,good products with smooth surface straight rib.

The specially designed screw and the advanced controlling system ensure excellent plasticization,high output and stable extruding.We have the co-extrusion type to use the recycled plastic to reduce the cost with high quality products.

The mold adopt special steel which made with Italian formula technology ,it has the characteristics of memory rebound.The mold is more wear-resistant and the service life is several times longer than ordinary mold.

One set mold can produce different thickness range ,such as 2mm-5mm,5mm-8mm,8mm-12mm,just by change the center of the mold.

The screen changer adopt silk screen circulation, altogether 4 pcs silk screen, 3 normal use, 1 standby . It does not need to stop when changing the silk screen .

There are 6 rollers on the front haul off machine and 3 rollers on the second haul off machine ,so the production line is more stable.

The haul off machine adopt helical gear

The haul off machine and the calibrating platform are on the same guide rail for convenient synchronous alignment adjustment.

We adopt fan cooling style, the cooling speed can be fast.So it won’t shrink after cutting, it can effectively reduce the error.And the speed of production can be more fast.

The oven’s material is 201# stain steel,there are total 4 meters with two 2 meter oven.The customer can choose to use one or two according the product need.

You need a product

You May Like

- Nearest port for product export

- Qingdao Port

- Delivery clauses under the trade mode

- FOB, CFR, CIF, EXW

- Acceptable payment methods

- T/T, L/C, MoneyGram, Credit Card, PayPal, Westem Union, Cash, Escrow