UPVC Windows and Doors Plastic Profile Machine Manufacturer with Ce

- US $43000.00

1 - 3 piece

- US $40000.00

4 - 10 piece

- US $38000.00

11 - 20 piece

group nameUPVC / PE profiles sheet making machine

-

Min Order1 piece

brand nameQingdao Tongsan

modelSJMS65/132

payment methodL/C, Western Union, MoneyGram, T/T, Paypal

-

update timeWed, 11 Nov 2020 13:14:45 GMT

Paramtents

Extruder type Conical double screw extruder

Extruder model SJMS65/132

Capacity 120-240kg/h

Raw material PVC +Caco3+attitives

Door frame width 100-300mm

Main motor power 37kw

Inventer ABB

Temperature Controller OMRON

Surface treatment Laminting or painting

Production time 60-90 days

pay terms 30% down payment +70% balance

warranty period 12 months

Packging & Delivery

Min Order1 piece

Briefing

Products:UPVC windows and doors,PVC ceiling ,PVC wall panel, PVC rain gutter

Detailed

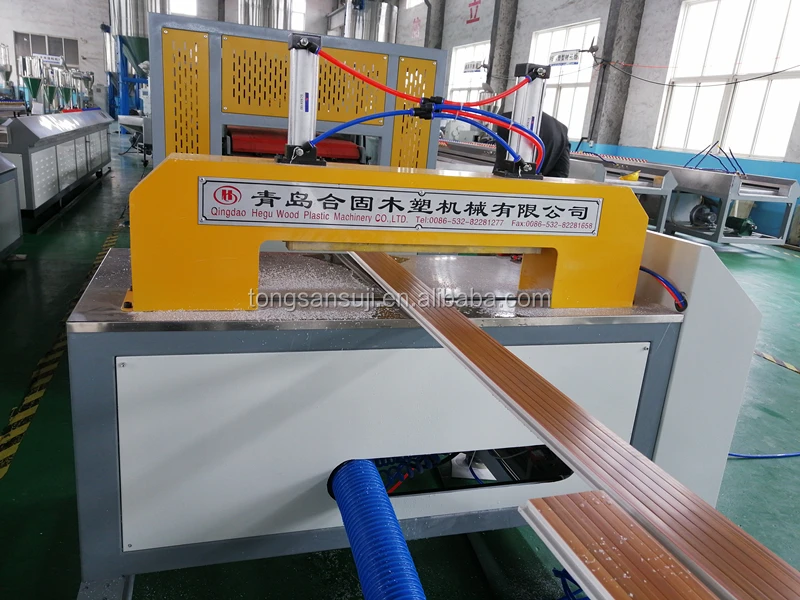

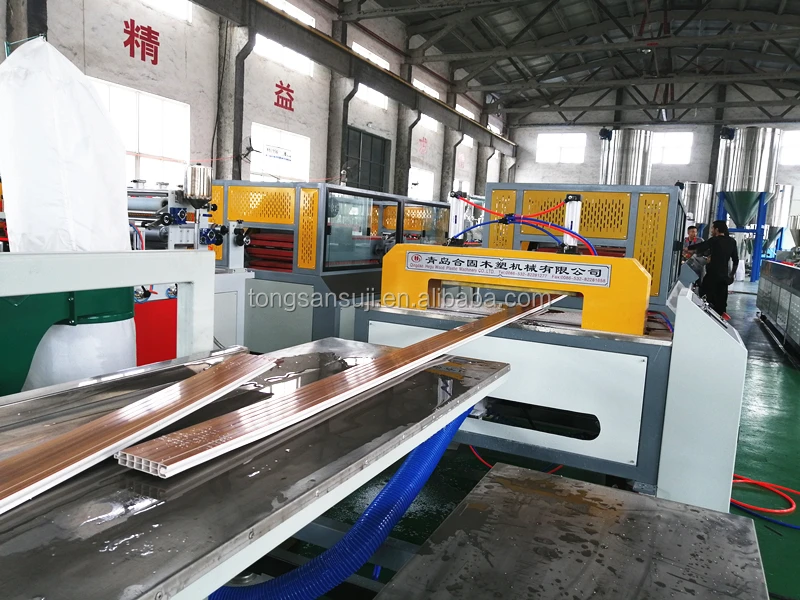

WPC door panel machine/UPVC windows profile extrusion machine introduction

This WPC profile machine/PVC UPVC windows profile extrusion machine is specializing in producing WPC door frame,wpc deckings, PVC plastic profiles including windows and doors, decorative plates,foam profile etc.By absorbing advanced technology from abroad, our company developed the large plastic profile extrusion line, which is equipped with conical double screw extruder, and it possesses the advantage of high degree automation, stable performance,high output and efficiency, etc.

model | YF180 | YF240 | YF300 | YF400 | YF500 | YF600 |

max width | 180MM | 240MM | 300MM | 400MM | 500MM | 600MM |

extruder | SJZ51/105 | SJZ65/132 | SJZ65/132 | SJZ80/156 | SJZ80/156 | SJZ80/156 |

main power | 22KW | 37KW | 37KW | 55KW | 55KW | 75KW |

capacity | 100-150KGH | 150-200KGH | 150-200KGH | 250-300KGH | 250-300KGH | 300-350KGH |

PVC Co-extrusion window profiles making process

Function:Mixing all raw materials together by hot mixer and so then can compound well,then cooling by the cold mixer preventreaction.

Working process:Automatic loading feeder--6-10min hot mixing--10-15min cooling

In order to avoid pollution, the mixer needs to be alone in a room. In addition, the mixed raw materials can be stored in silos,then transported directly from the silo to the extruder.

2,PVC window profiles extrusion line

Function and working process:

Automatic loading ----Conical double screw extruder +Co-extruder---die mould---calibrator platform cooling----haul off

device---Automatic cutting machine---Productus stacker

Special design screw for PVC powd erextrusion,SIEMENS brand motor,famous brand gear box,with automatic loading and feeder.In order to cooling the products well,adopt the cauum pump and water pump,two sets water tank.All parts contact with water are made by stainless steell.The haul off device clamped the products by the rubber block, then the movement of the rubber block pulls the product forward.Automatic cutting machine can customized cut the final products at the required length .It has the functions of measuring cutting and accumulative counting.It adopt with the dust collector avoid pollution.Carry and support the cutted final product, and then arrange neatly.Made of stainless steel, the slide rail is equipped with a rubber protective layer.

3,ASA co-extrusion and rubber strip co-extrusion extruder

The ASA color won't fading in the outdoor under sunshine for 10 years.And it is cheaper than laminating .

ASA materials can not only resist degradation, aging, and fading caused by ultraviolet radiation, but also oxidation in the

atmosphere and high temperature during processing will not cause decomposition or discoloration. Test results show that the anti-aging performance of ASA is more than 10 times that of ABS.

SJ30/25 for rubber co-extrusion,It can get the final products with the rubber sealing,it is save labor and cost less.

4,PVC window and door profiles mould

We can design the mold according your requirments,mould material: 3cr17,the special high-quality mold steel

We offer the mold for 60 /65/80/85 series PVC window and doors,the co-extrusion type for ASA surface and sealing rubber.

5,SWP360 Plastic crusher

The crusher used to recycling the waste products ,then cutting them into small flakes.

6,SMW-500 high speed PVC Grinding machine

The high speed PVC grinding machine used to milling the PVC flakes into powder,so the waste PVC products can be recycled use.

7,20HP Water chiller :HANGKANG ANGES brand,Danfoss compressor

Cooling the recycle water which used to cooling the products,

so it can increace the production speed and get good products surface.

8,30A air compressor

Provide the air to the mold,cylinder for haul off device,cutter,and stacker

Extruder SJ65/132 with automatic loader

Conical double screw extruder SJ65/132

PVC door panel mold

PVC door panel water tank

Cooling calibrator platform

PVC door panel haul off device

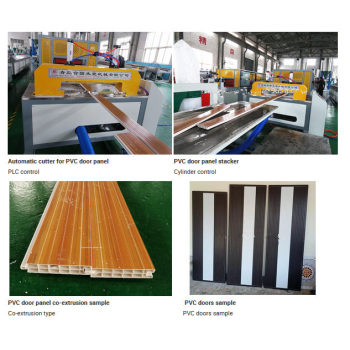

Automatic cutter for PVC door panel

PVC door panel stacker

PVC door panel co-extrusion sample

PVC doors sample

1 According to the opening method, it is divided into: fixed windows, top-hung windows, middle-hung windows, bottom-hung windows,vertical swing windows, side-hung doors and windows, pulley side-hung windows, pulley windows, side-hung lower doors and windows,sliding doors and windows, sliding side-opening Windows, folding doors, floor spring doors, lifting sliding doors, sliding folding doors, and inverted sliding doors.

2. According to performance, it is divided into: ordinary doors and windows, sound insulation doors and windows, and thermal insulation doors and windows.

3. According to the application part, it is divided into: inner doors and windows, outer doors and windows.

The characteristics of different types of windows

1. Casement window

The advantages are large opening area, good ventilation, good airtightness, sound insulation, heat preservation and

impermeability. The inward opening type is convenient for cleaning windows; the outward opening type does not take up space when opening. The disadvantage is that the window is small and the field of view is not wide. Opening windows outside the wall takes up a space outside the wall and is easily damaged when strong winds blow; and windows opening inside takes up part of the indoor space. It is inconvenient to use screens, and it is inconvenient to use screens and curtains when opening windows. If the quality is not good enough, there may be rain.

2, sliding window

The advantages of sliding windows are simple, beautiful, large window width, large glass blocks, wide view, high lighting rate,convenient glass cleaning, flexible use, safety and reliability, long service life, open in a plane, less space, and convenient installation of screens Wait. The most popular one is the sliding window. The disadvantage is that the two windows cannot be opened at the same time, at most they can only be opened halfway, and the ventilation is relatively poor; sometimes the airti-ghtness is slightly poor. Sliding window: divided into left and right, up and down sliding. Sliding windows have the advantages of not occupying indoor space, beautiful appearance, economical price, and better sealing. It adopts high-grade slide rails, which can be opened flexibly with one push. With a large piece of glass, it not only increases indoor lighting, but also improves the overall appearance of the building. The window sash has a good stress state and is not easy to damage, but the ventilation area is limited.

3, downward suspension

This is a kind of aluminum alloy and plastic steel window that appeared later. It is a new form developed on the basis of casement windows. It has two opening methods, which can be opened horizontally or pushed away from the top. When the casement window is closed, pull the upper part of the window inward to open a gap of about ten centimeters. That is to say, the window can be opened from the top down a little, and the opened part is suspended in the air and fixed with the window frame by hinges. , So it is called the lower suspension. Its advantages are: it can be ventilated, but also can ensure safety. Because of the hinges, the windows can only be opened with a seam of ten centimeters, and hands cannot be reached from the outside. It is especially suitable for use when there is no one at home. This function is not limited to casement windows, sliding windows can also be opened downwardly.

4, swing the door

There are single-open and double-open swing doors: single-open doors refer to only one door panel, while double-open doors have two door panels. Swing doors are divided into one-way opening and two-way opening. One-way opening means that the door can only be opened in one direction (only push in or out). Two-way opening means that the door leaf can be opened in two directions (such as a spring door). Side-hung doors are distinguished from other opening methods, because the doors also have mobile opening, upturning,rolling curtain lifting, vertical lifting, rotating and so on.

5. Sliding doors

Originated from China and spread to North Korea and Japan through Chinese culture. Literally speaking: push and pull the door; from the material point of view: there are wood, metal, organic, and inorganic materials; from the use point of view: for the door of bookcases, wall cabinets, bedrooms, living rooms, and exhibition halls . Sliding doors originated in China and spread to Korea and Japan through Chinese culture. The exact time cannot be verified, but scattered sliding doors can be seen in some ancient Chinese paintings, such as the landscape paintings of the Song Dynasty. The original sliding door was only used for the sliding door of the bedroom or dressing room closet, but with the development of technology and the diversification of decoration methods,from the traditional plate surface to glass, fabric, rattan, aluminum alloy profiles, from sliding doors, From folding door to partition door, the function and use range of sliding door are constantly expanding. In this case, the use of sliding doors began to become diverse and abundant. In addition to the most common partition doors, sliding doors are widely used in bookcases, wall

cabinets, living rooms, showrooms, sliding doors, etc.

You need a product

You May Like

- Nearest port for product export

- Qingdao Port

- Delivery clauses under the trade mode

- FOB, CFR, CIF, EXW

- Acceptable payment methods

- T/T, L/C, MoneyGram, Credit Card, PayPal, Westem Union, Cash, Escrow