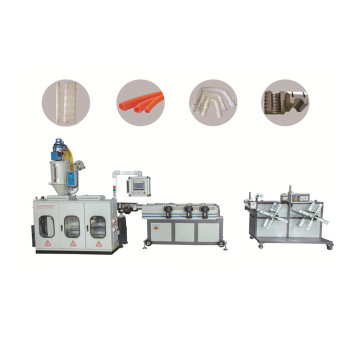

PE PP EVA PVC PA High Speed Single Wall Corrugated Pipe Extrusion Line / Single Wall Pipe Macking Machine From Qingdao Tongsan

- US $34000.00

1 - 3 piece

- US $33000.00

4 - 10 piece

- US $32000.00

11 - 20 piece

group nameSingle Wall Corrugated Pipe Making Machine

-

Min Order1 piece

brand nameQingdao Tongsan

modelSJMS65B

payment methodL/C, Western Union, MoneyGram, T/T

-

update timeSat, 10 Oct 2020 15:29:22 GMT

Paramtents

Suitable raw material PP PE PVC EVA PA

Pipe diameter 12-50mm

Extruder model SJMS65

Main motor 30kw

Extruder capacity 60-80kg/h

Line speed 20-30m/min

Mold block raw material 40 Cr

Mold block quantity 72 pairs

Cooling type water cooling

Pipe application single wall corrugated pipe

Winder device double position winder

Packging & Delivery

Min Order1 piece

Briefing

It can reach 20-30 m/min,suitable for the pipe 5-50mm.

Detailed

Single wall corrugated pipe making machine

SJDBGZ series plastic single wall corrugated pipe extrusion line can produce PP/PE/EVA/PVC/PA corrugated pipe.

Corrugated pipe produced by our machine has the features of high production speed, even corrugated shape,straight pipe seam, and smooth surface.

By equipped with vacuum pump and vacuum type mould,it can produce difffernt use corrugated pipe with joint(wash basin drain pipe,air conditioner pipe, shisha hookah hose pipe etc).

We have three kinds of single wall corrugated pipe making machine:

(1)Normal speed single wall corrugated pipe machine.The line speed of the machine can upto 8-12m/min.

(2)High speed single wall corrugated pipe machine.The line speed of the machine can upto 20-25m/min.

(3)Vacuum type single wall corrugated pipe machine. Used for making pipe with joint.

Corrugated pipe mold making:

we have our own workshop and CNC machines to make corrugated pipe molds by ourself, we also has design team for design the corrugated pipe molds according to customer's requirements.

Company Information

Qingdao Tongsan PLastic Machinery Co.,LTD

Qingdao Tongsan Plastic Machinery Co., LTD is a professional plastic extrusion machines manufacturer which stands by the Jiaozhou Bay. Converged with the national first-class scientific talests, our company is engaged in the study of new- type plastic machines and the conversion of international high-and -new technology. Cooperating with scientific research instifutions and institutions of higher education , we are converting the newest scientific payoffs at top speed. We will supply you the high-performance and high-tech plastic machines, Hollow sheet machine, Corrugated pipe machine, PVC and WPC foam board making machine.

Packaging & Shipping

Fastening of fixed Steel Wire with plastic Film wound Wood Block

Our Services

- We will provide the Feasibility Analysis Report for the wood plastic project.

- We will provide the model selection and technical parameter for wood-plastic machine.

- We will provide the design for the plant and electric powder accounting for the facilities.

- We will provide the design for wood plastic formula according to the product requirement.

- We will provide the technology of wood plastic product surface treatment.

- We will provide technique training for operator.

- We will provide solution for the practical problem during the production.

- We will install and test machine for free.

- We will provide turnkey project to customers.

You need a product

You May Like

- Nearest port for product export

- Qingdao Port

- Delivery clauses under the trade mode

- FOB, CFR, CIF, EXW

- Acceptable payment methods

- T/T, L/C, MoneyGram, Credit Card, PayPal, Westem Union, Cash, Escrow