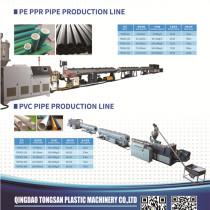

75-250mm SJ75 HDPE PP PPR Plastic pipe extruder making machine

group namePP PE PPR PVC Pipe Machine

-

Min Order1 piece

brand nameQingdao Tongsan

modelSJ75

payment methodT/T, L/C, MoneyGram, Credit Card, PayPal, Westem Union, Cash, Escrow

-

update timeWed, 28 Oct 2020 10:58:00 GMT

Paramtents

Pipe diameter 75-250mm

Main extruder SJ75/33

Extruder motor 90kw

Capacity 260-300kg/h

Production speed 5-20m/min

Motor brand SIEMENS

Inventer ABB

Temperture control OMRON

Packging & Delivery

Min Order1 piece

Briefing

Detailed

75-250mm Plastic PE PP PPR pipe making machine

We have differen model of PE pipe machine for making 16-630mm PE pipe

Extruder model | Pipe diameter |

SJ50/30 | 16-25mm |

SJ65/33 | 16-63mm |

SJ75/30 | 20-110mm |

SJ75/33 | 75-250mm |

SJ90/33 | 160-450mm |

SJ120/33 | 315-630mm |

Feature of Tongsan PE pipe making machine:

1,The main machine adopts screws specially used for polyolefin. Equipped with auto vacuum charger and auto constant temperature dryer hopper, it possesses features of high production, good plasticization and stable extruding.

2,Die heads of helical type and basket type are perfect for polyolefin, and can help to produce sound melting pressure, and improve the plasticization capacity. Meanwhile, stable material-flow and pressure grade can be guaranteed.

3, Advanced vacuum calibrating method improves the cleanliness and hardness of surface. Reasonable high-speed sprinkling cooling water tank guarantees the pipe quality and high speed stable extruding.

4,Caterpiller of the hauling machine adopts anti abrassion alloy material, which realizes stable traction, wide frequency adjustment range and long lifespan.

5,New generation auto dust-free cutting blade realizes smooth cutting secant, high precison and low noise.

Detailed Images

the complete extrusion line for making PE pipe, including auto feeder, extruder, die and mold, cooling tank, haul off machine, cutting machine, stacker

the co-extruder can make the marking line on the pipe.

we will design the co-extruder according to the pipe marking line requirements.

for different size of PE pipe making, the quantity and capacity of water and vacuum tank may also different.

according to the PE pipe size, we shall equip double caterpillar haul off, three caterpillar haul off, four caterpillar haul off, six caterpillar haul off.

5, and automatic cutting machine without dust:

the cutter is equipped with PLC touch screen system,

the user can set the cutting length and it shall cut automatically.

the stacking device is 6 meter length, it shall stack the PE pipes together automatically.

7, Electricity control system.

| Electric applicant: 380V/50HZ/3 PHASES or customized |

| 1). ABB inverter 2). Siemens contactor 3). Omron temperature controller 4). Siemens motor 5). Taiyuan Yuanli Pump 6). Guomao brand vertical gearbox 7). cables:equipped cables for connection the machines to the electricity cabinet. The complete extrusion line electricity needs shall all connected to this cabinet. 8). heat ventilation of cabinet is designed with blowing fans:6 sets 9). Siemens PLC control system is optional |

You need a product

You May Like

- Nearest port for product export

- Qingdao Port

- Delivery clauses under the trade mode

- FOB, CFR, CIF, EXW

- Acceptable payment methods

- T/T, L/C, MoneyGram, Credit Card, PayPal, Westem Union, Cash, Escrow