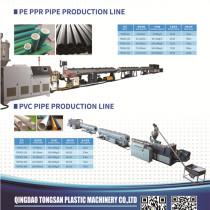

315-630mm SJ120 HDPE PP PPR Plastic pipe extruder making machine

group namePP PE PPR PVC Pipe Machine

-

Min Order1 piece

brand nameQingdao Tongsan

modelSJ120

payment methodT/T, L/C, MoneyGram, Credit Card, PayPal, Westem Union, Cash, Escrow

-

update timeWed, 28 Oct 2020 11:03:32 GMT

Paramtents

Pipe diameter 315-630mm

Main extruder SJ120/33

Extruder motor 250kw

Capacity 500-600kg/h

Production speed 5-20m/min

Motor brand SIEMENS

Inventer ABB

Temperture control OMRON

Packging & Delivery

Min Order1 piece

Briefing

Detailed

hdpe pipe manufacturing machine,plastic pipe production line polypropylene pipes

With this PE production line you can extrude high quality large diameter water and gas supply pipes .This pipes produced by our line have excellent stiffness and flexibility ,resistance to creep deformation ,excellent heat-linkage .Large dismeter HDPE pipes start to play very important role in the city water and gas supply systems.

We have differen model of PE pipe machine for making 16-630mm PE pipe

Main technical parameter

| NO.Parameter | Technical parameter | ||||

| 1 | Mold | SJ-65 | SJ-70 | SJ-75 | SJ-90 |

| 2 | Max.extruding capacity | 120 kg/h | 200 kg/h | 300 kg/h | 450 kg/h |

| 3 | Main drive power | 37 KW | 55 KW | 90 KW | 132KW |

| 4 | Filter changing method | Durable filter | Durable filter | Durable filter | Durable filter |

| 5 | Heating power | 24 KW | 30 KW | 36KW | 42 KW |

| 6 | Sizing way | Vacuum sizing | Vacuum sizing | Vacuum sizing | Vacuum sizing |

| 7 | Pipe specification | Φ16~Φ63 | Φ20~Φ110 | Φ75~Φ250 | Φ160~Φ450 |

| 8 | Cooling way | Spray+immersion | Spray+immersion | Spray+immersion | Spray+immersion |

| 9 | Tracting type | Roller type tractor | Roller type tractor | Roller type tractor | Roller/caterpillar band type for hard pipe |

| 10 | Tractor driving power | 1.5 KW | 2.2 KW | 3 KW | 4 KW |

| 11 | Winding motor | 6 N.m | 6 N.m | 16 N.m | 20 N.m |

| 12 | Installation power | 80 KW | 120 KW | 180 KW | 240 KW |

| 13 | Overall dimension | 12m×1.6m×2.6m | 12.2m×1.6m×2.7m | 13m×1.6m×2.7m | 15.8m×2.3m×2.8m |

| 15m×3m×2.6m | 16.5m×3m×2.7m | 17.5m×3m×2.7m | 21m×2.3m×2.8m | ||

1. The extruder adopts frequency converter control which has the features of easy adjustment, reliable running, stable working and low energy consumption. It adopts independent electric cabinet and it is easy for the whole machine's centralized control and operation.

2. The screw bolt and barrel of the extruder is made of good quality nitriding steel. The design is reasonable and the plasticizing effect is excellent and it features stable production.

3. Shaping of the pipe adopts center material feeding mold and vacuum sizing. Cooling method is the combination of spraying and leach so the precision of the pipe size is high and the outlook is good.

4. It adopts special-purpose roller type tractor and the pipe will not deform easily due to plasticity.

5. Soft pipe rolling machine adopts torque motor control which overcomes disadvantage of tension. It adopts independent electric cabinet control which is convenient for independent control and operation during production.

6. When producing small diameter pipe change winder to coiler for hard pipe and equip the line with suitable extruding mold, hard pipe can be produced. When producing big diameter pipe, it shall adopt caterpillar type tractor and change winder to pipe rack and equipped with suitable extruding mold and pipe cutting device to produce hard pipe.

1. Process flow:

Plastic granules → Vacuum feeding →Single screw extruder → Co-extruder for mark line→ mould → vacuum tank →water cooling tank → haul off machine → cutting machine → stacker or automatic belling winder machine

1.Single screw extruder and mark line co-extruder

2.Die head. Due to the diameter, it can be design according customer requirments

3.Vacuum tank and water cooling tank: due to diameter, it can be designing of single, double vacuum chambers

4.Haul-offs: due to diameter, it can be designing of double, three, four, six, eight caterpillars

5.Cutter: due to diameter, it can be designing of saw cutter or planetary cutter

6.Stacker or automatic winder machine

2,Machine listNo. | Equipment list for PP PE PPR pipe manufacturing plant | Quantity |

1 | Mixing machine | 1 set |

2 | Auto feeder | 2 sets |

3 | Single screw extruder | 1 set |

4 | Die head and sizing mold | customized |

5 | 1st vacuum cooling tank | 1 set |

6 | 2nd water cooling tank | 1 set |

7 | haul off device | 1 set |

8 | auto cutting machine | 1 set |

9 | Laser printer or ink jet printer | 1 set |

10 | Plastic pipe stacker | 1 set |

11 | Plastic pipe automatic winder machine | 1 set |

12 | Waste products crushing machine | 1 set |

13 | Spare pparts for production line | 1 set |

14 | Air compressor | 1 set |

15 | Water chiller | 1 set |

3,Plastic pipe making machine details

1, High effective single screw extruder with PLC control system.

About HDPE Pipe Application

HDPE pipes must bear a certain pressure. PE resins with high molecular weight and good mechanical properties are usually used, such as HDPE resins. LDPE resin has low tensile strength, differential pressure resistance, poor rigidity, poor dimensional stability during molding and difficult connection, and is not suitable as a material for water supply pressure pipes. However, due to its high hygienic index, LDPE especially LLDPE resin has become a common material for the production of drinking water pipes. LDPE and LLDPE resins have low melt viscosity, good fluidity and easy processing, so their melt index can be selected in a wide range, usually with MI between 0.3-3g/10min.

HDPE pipe is a good pipeline. It should not only have good economy, but also have a series of advantages such as stable and reliable interface, impact resistance, crack resistance, aging resistance, corrosion resistance, etc. Compared with traditional pipes, HDPE piping system has The following series of advantages:

1,Reliable connection: The polyethylene pipe system is connected by electric heat melting, and the strength of the joint is higher than the strength of the pipe body.

2,Good low-temperature impact resistance: The low-temperature embrittlement temperature of polyethylene is extremely low, and it can be used safely in the temperature range of -60-60ºC. During construction in winter, because the material has good impact resistance, the pipe will not be brittle.

3,Good stress crack resistance: HDPE has low notch sensitivity, high shear strength and excellent scratch resistance, and its environmental stress crack resistance is also very outstanding.

4,Good chemical resistance: HDPE pipelines can withstand the corrosion of a variety of chemical media, and the chemical substances in the soil will not cause any degradation to the pipeline. Polyethylene is an electrical insulator, so it will not rot, rust or electrochemical corrosion; in addition, it will not promote the growth of algae, bacteria or fungi.

5,Aging resistance and long service life: The polyethylene pipe containing 2-2.5% evenly distributed carbon black can be stored or used outdoors for 50 years without being damaged by ultraviolet radiation.

6,Good wear resistance: The comparison test of the wear resistance of HDPE pipes and steel pipes shows that the wear resistance of HDPE pipes is 4 times that of steel pipes. In the field of mud transportation, HDPE pipes have better wear resistance than steel pipes, which means that HDPE pipes have a longer service life and better economy.

7,Good flexibility: The flexibility of HDPE pipeline makes it easy to bend. In engineering, obstacles can be bypassed by changing the direction of the pipeline. In many cases, the flexibility of the pipeline can reduce the amount of pipe fittings and reduce installation costs.

8,Small water flow resistance: HDPE pipe has a smooth inner surface, and its Manning coefficient is 0.009. The smooth performance and non-adhesive characteristics ensure that HDPE pipes have a higher conveying capacity than traditional pipes, and also reduce the pressure loss of the pipeline and the energy consumption of water transmission.

9,Convenient handling: HDPE pipes are lighter than concrete pipes, galvanized pipes and steel pipes. It is easy to handle and install. Lower manpower and equipment requirements mean that the installation cost of the project is greatly reduced.

10,Various new construction methods: HDPE pipeline has a variety of construction technologies. In addition to traditional excavation methods, it can also use a variety of new non-excavation technologies such as pipe jacking, directional drilling, liner, It is a good choice for some places where excavation is not allowed.

Other products

You need a product

You May Like

- Nearest port for product export

- Qingdao Port

- Delivery clauses under the trade mode

- FOB, CFR, CIF, EXW

- Acceptable payment methods

- T/T, L/C, MoneyGram, Credit Card, PayPal, Westem Union, Cash, Escrow